Recurvation-prevention aluminum electrolysis cell upright column flexible bus bar

An aluminum electrolytic cell and soft busbar technology, applied in the field of column soft busbars, can solve the problems of increasing the tensile stress of the anode busbar and reducing the operating space, so as to reduce the tensile stress and stress deformation, avoid stretching, and ensure safe operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

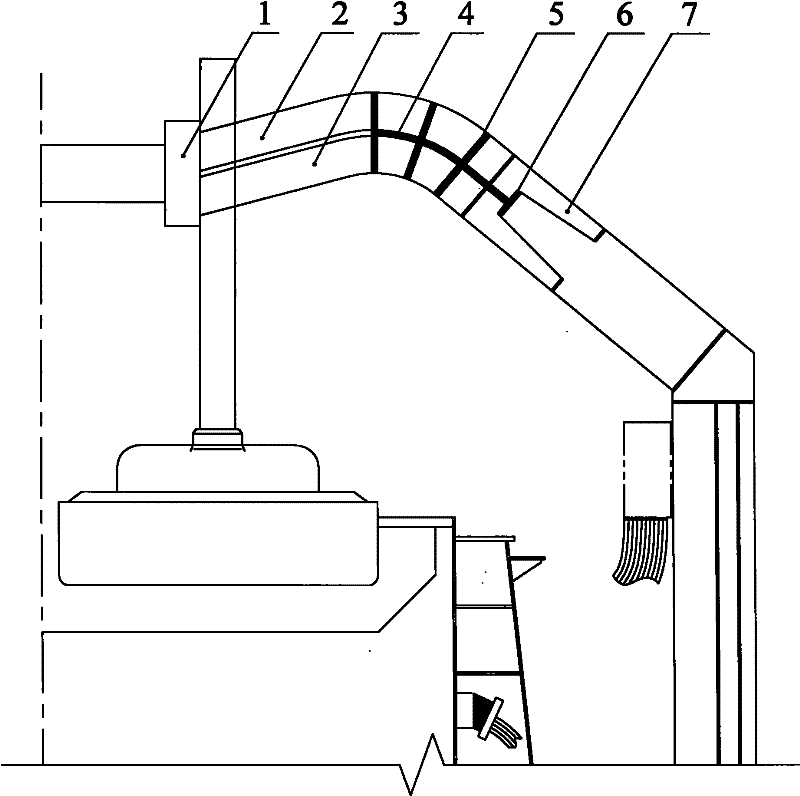

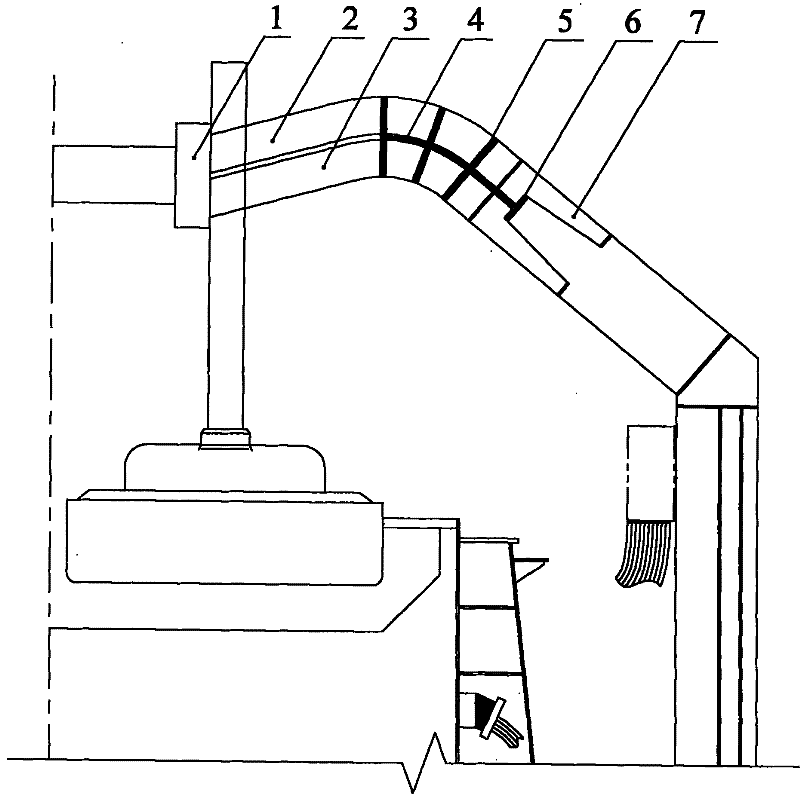

[0016] Such as figure 1 As shown, the aluminum electrolytic cell column soft busbar with anti-bending of the present invention includes the upper column soft busbar 2 and the lower column soft busbar 3, the front end of the column soft busbar is connected to the anode busbar 1, and the rear end is connected to the connecting block 7 , an arc-shaped steel plate 4 is installed between the soft busbar 2 of the upper column and the soft busbar 3 of the lower column. The length of the arc-shaped steel plate 4 is 1 / 2 of the length of the column soft busbar, the width of the arc-shaped steel plate 4 is less than the total width of the column soft busbar, and greater than half of the total width of the column soft busbar, and the thickness of the arc-shaped steel plate 4 is 2mm. A bottom steel plate 6 is welded at the lower end of the curved steel plate 4 . The length of the bottom steel plate 6 is 50mm, the width of the bottom steel plate 6 is smaller than the width of the curved st...

Embodiment 2

[0018] The structure is basically the same as in Example 1, except that the thickness of the curved steel plate 4 is 6 mm, the length of the bottom steel plate 6 is 150 mm, the thickness of the bottom steel plate 6 is 6 mm, the width of the bottom steel plate 6 is equal to the width of the curved steel plate 4, and the steel strip The quantity of 5 is 3, the thickness of the steel strips 5 is 2mm, the width of the steel strips 5 is 30mm, and the distance between the steel strips 5 is 200mm.

Embodiment 3

[0020] The structure is basically the same as in Example 1, except that the thickness of the curved steel plate 4 is 10 mm, the length of the bottom steel plate 6 is 300 mm, the thickness of the bottom steel plate 6 is 10 mm, the width of the bottom steel plate 6 is equal to the width of the curved steel plate 4, and the steel strip The number of 5 is 5, the thickness of the steel strips 5 is 3 mm, the width of the steel strips 5 is 50 mm, and the distance between the steel strips 5 is 300 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com