Heat exchange plate with alternate intercommunicating microchannel net structure and manufacturing method thereof

A network structure, interlaced technology, applied in the direction of heat exchange equipment, lighting and heating equipment, laminated components, etc., can solve the problems of difficult large-scale use, miscellaneous spraying deposition methods, etc., to achieve high cost and increase specific surface area , the effect of excellent boiling enhancement performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

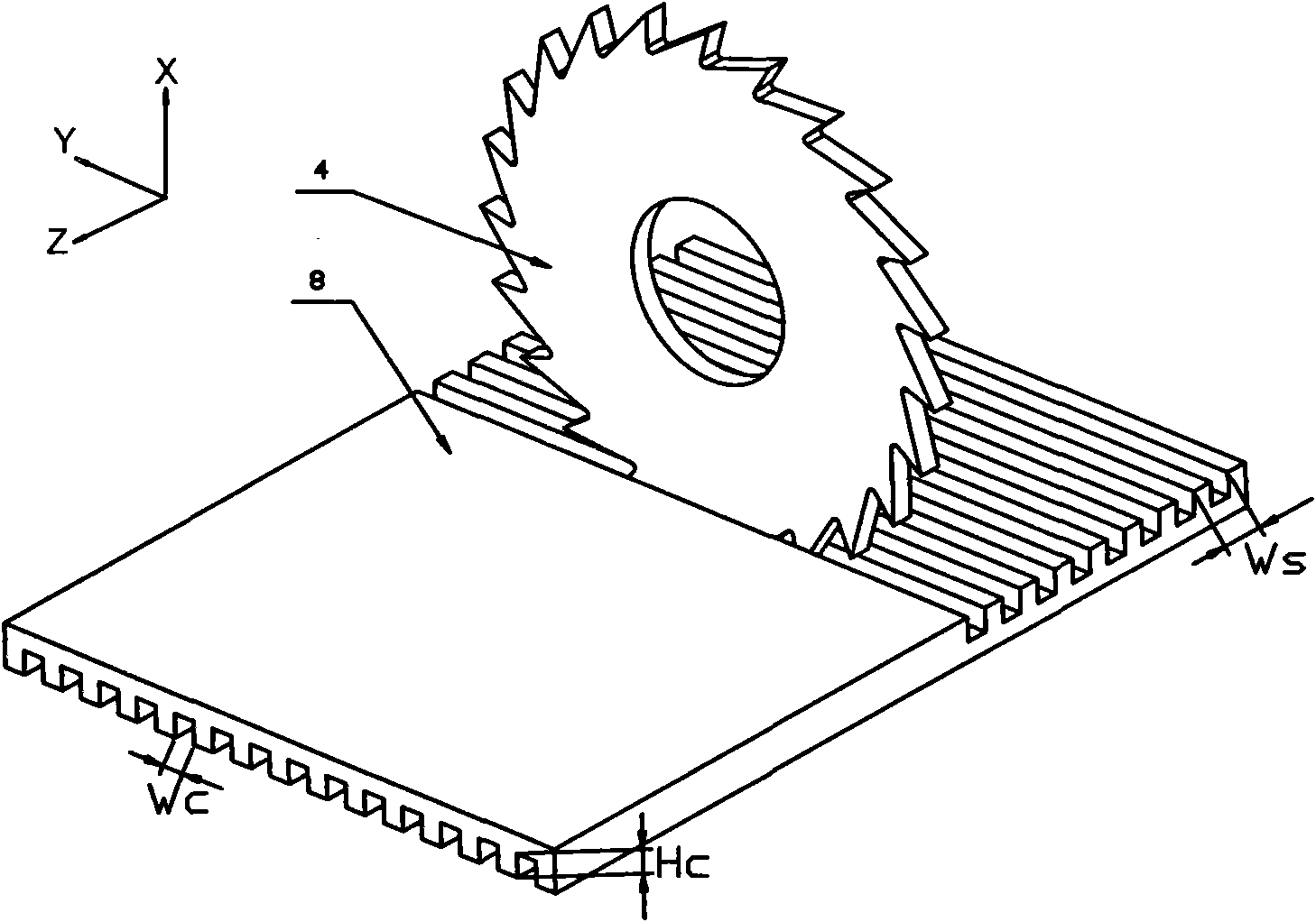

[0033] Taking the processing of 2mm thick, 0.4mm microchannel width, 0.4mm fin width, and aluminum bronze substrate as an example, the process is as follows:

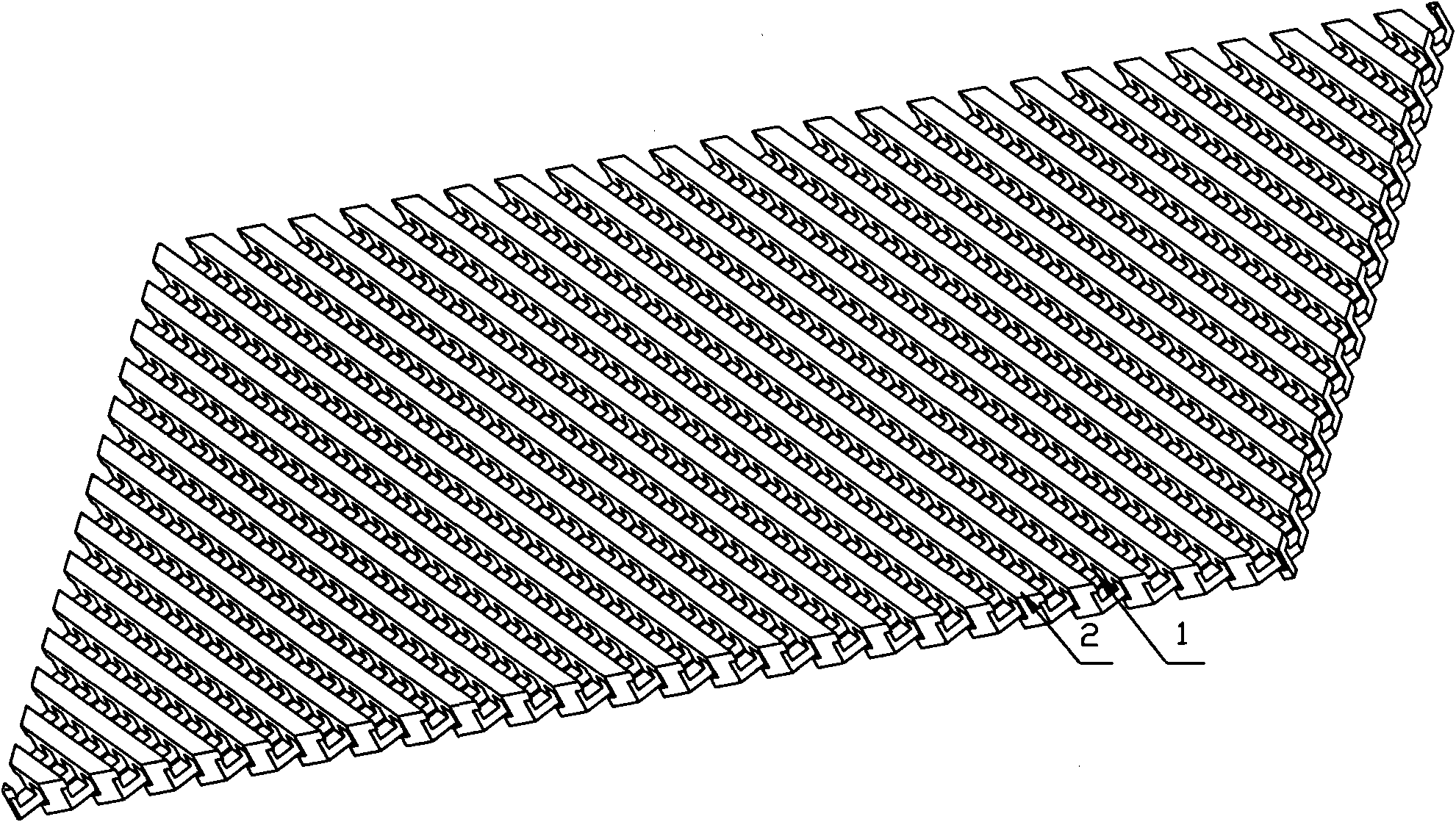

[0034] (1) Fix the thin plate to be processed on the indexing head of the milling machine with a fixture, and adjust the angle between the workpiece edge and the main shaft by adjusting the indexing head to realize the processing of microchannels at any angle on the workpiece. In this example, choose 45 degrees, that is, as figure 1 The channel shown is at a 45 degree angle to the sideline.

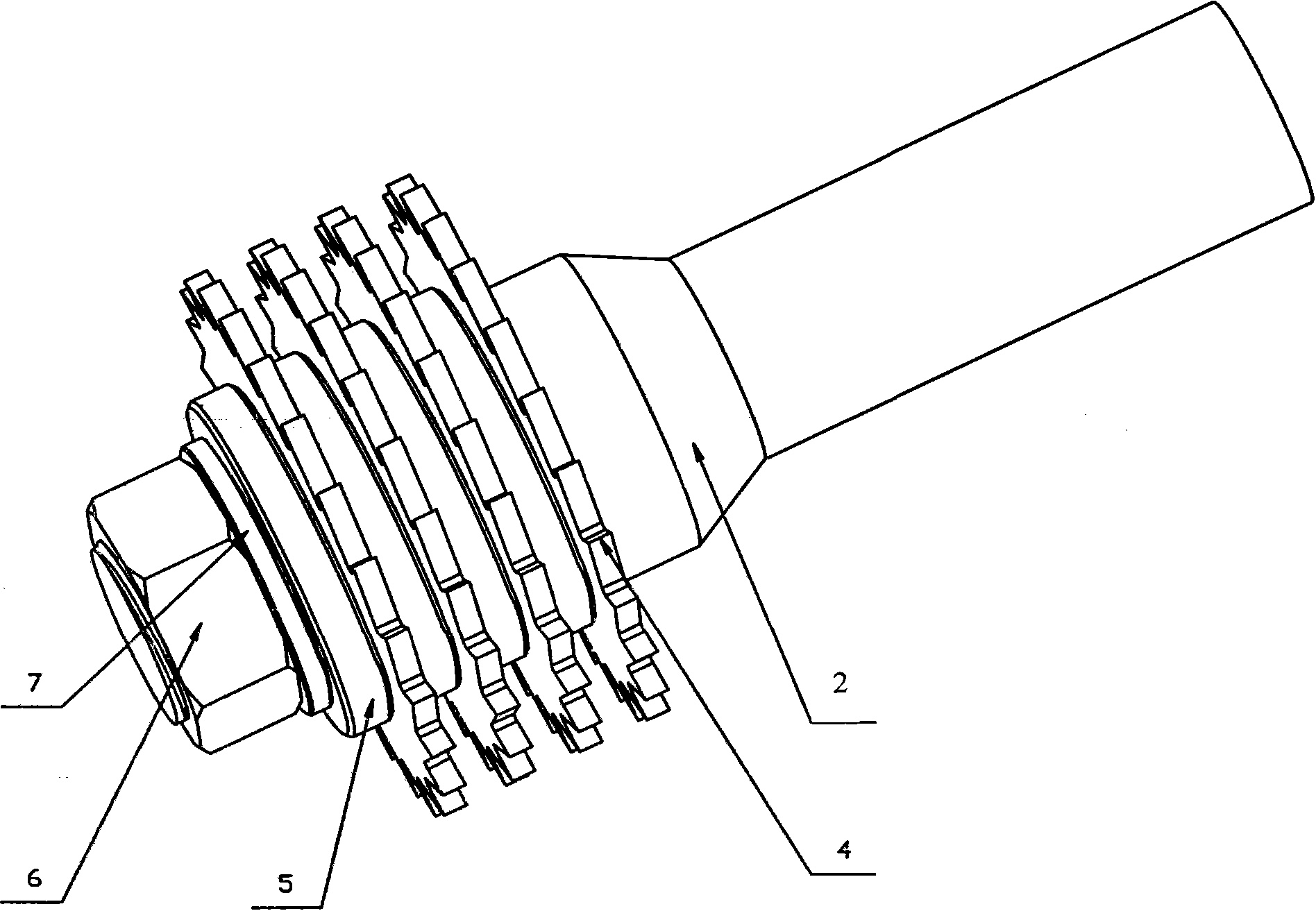

[0035] (2) First, use multiple superimposed milling cutters on one side of the board (such as figure 2 ) is processed by milling the micro-channel array by interval jumping method to improve the precision. Such as Figure 4 The microchannel array shown is not processed sequentially from front to back, but is processed by pressing multiple milling cutters with a large-thickness tool shim (in this example, the thickness is 3 ribs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com