Test piece-hanging frame for testing high-pressure kettle

A technology for autoclave and testing, which is applied in the field of test piece racks for autoclave testing, which can solve problems such as inconvenience, interference, and melting, and achieve the effects of reliable performance, simple structure, and ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

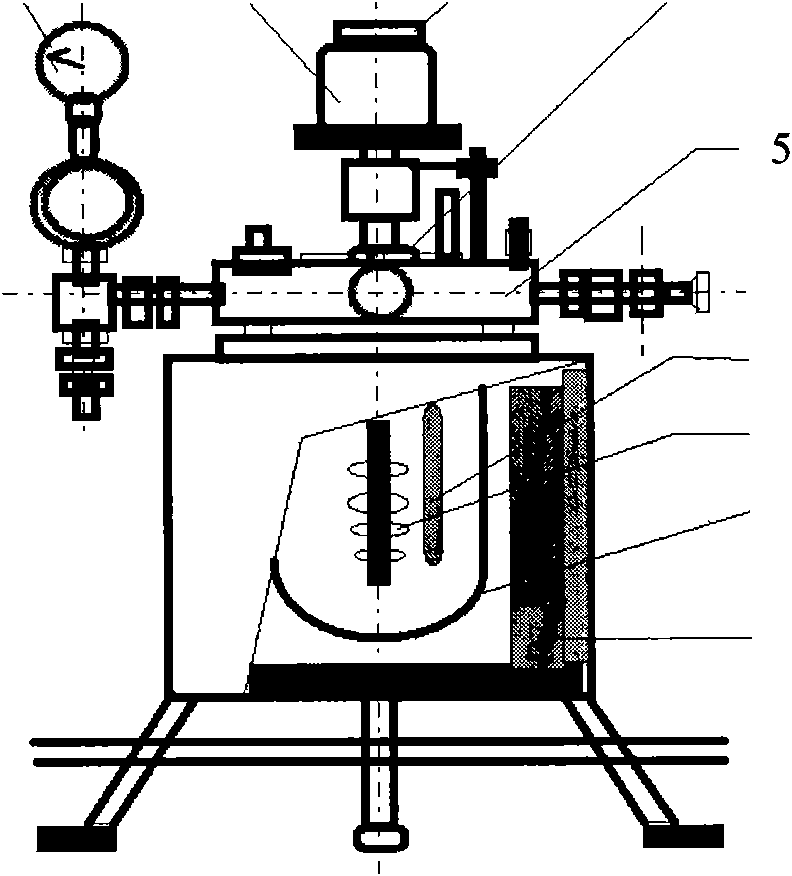

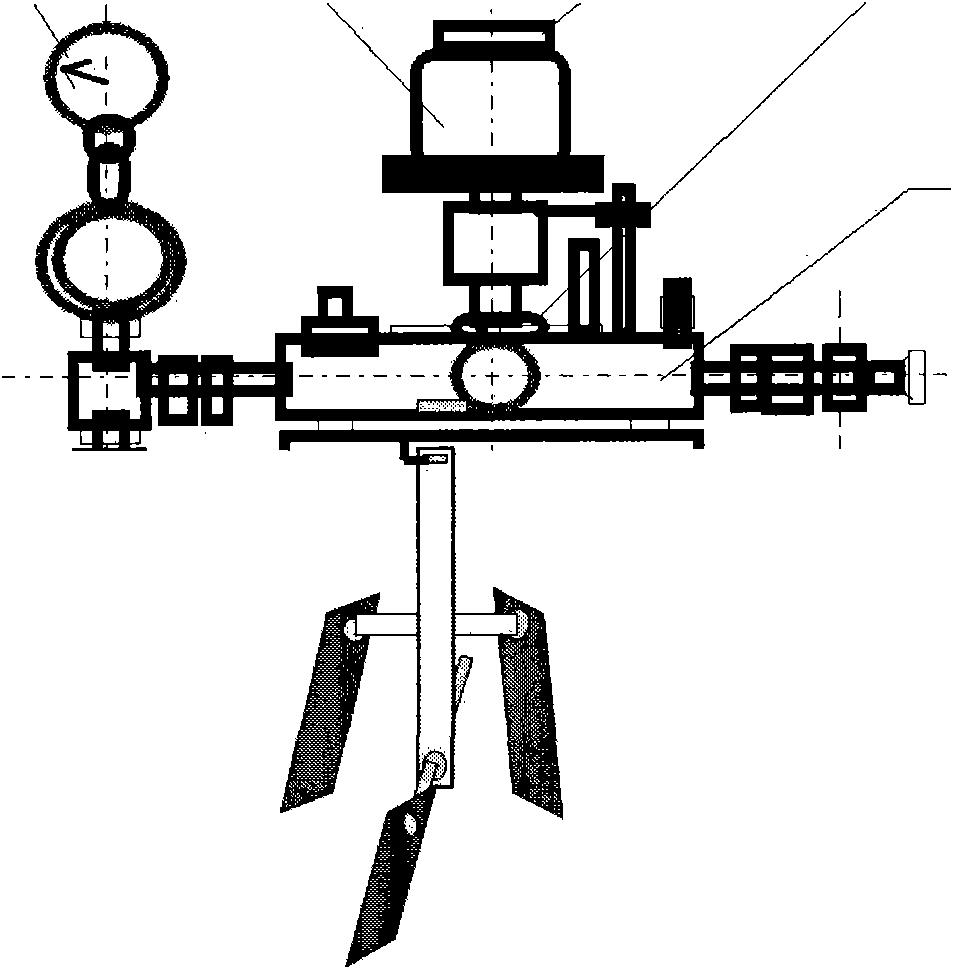

[0009] See attached figure 2 , this figure provides a detailed schematic diagram of the autoclave structure, and 5 in the figure indicates the lid of the autoclave. The present invention is used in an autoclave, and the hanger is fixed by the lid of the kettle, so that the corrosion research test pieces are immersed in different positions of the kettle barrel, and the kettle barrel withstands a test environment as high as 350°C and 19.0MPa.

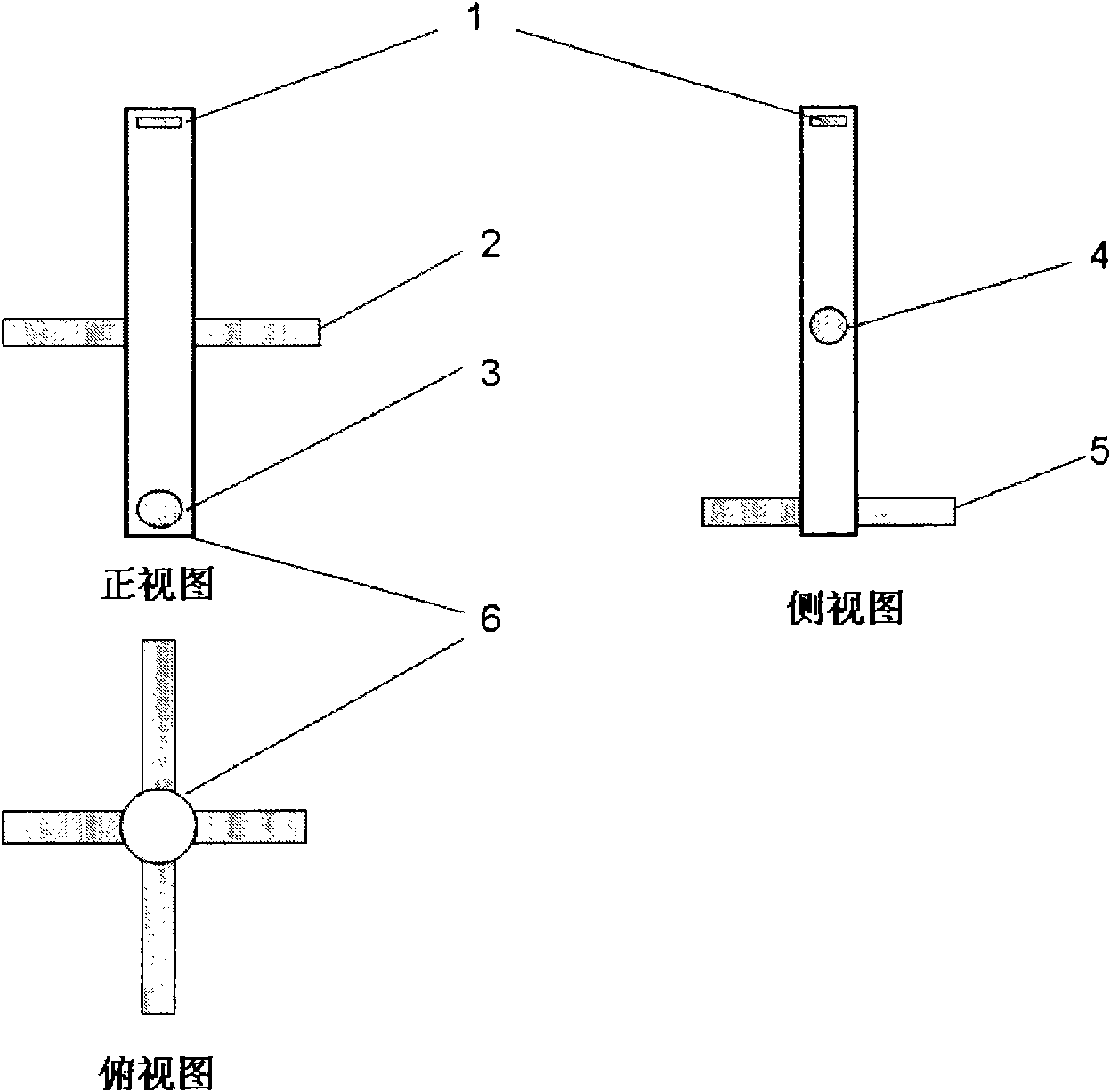

[0010] See attached figure 1 , the top of the ceramic column 6 is provided with a groove 1, the groove is hung on the top cover of the autoclave, the circular support rod 2 in the middle passes through the circular hole 4 in the middle of the ceramic column and is fixed, and the circular support rod 5 at the bottom passes through the ceramic column The round hole 3 at the bottom is fixed; the two round rods are used to hang the test piece for corrosion test respectively, and each round rod can hang two test pieces for parallel test rese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com