Transfer printing method, photomask for transfer printing and manufacturing method thereof

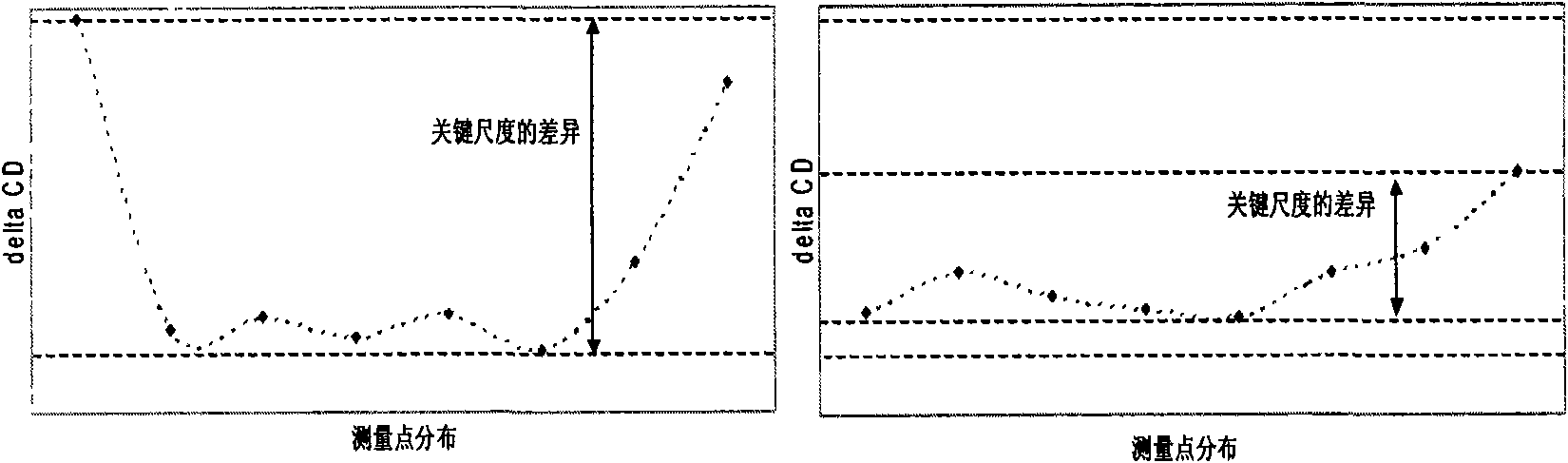

A photomask and graphics technology, applied in the field of transfer photomask and its manufacturing, can solve the problems of key scale differences, and achieve the effect of narrowing the gap and reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

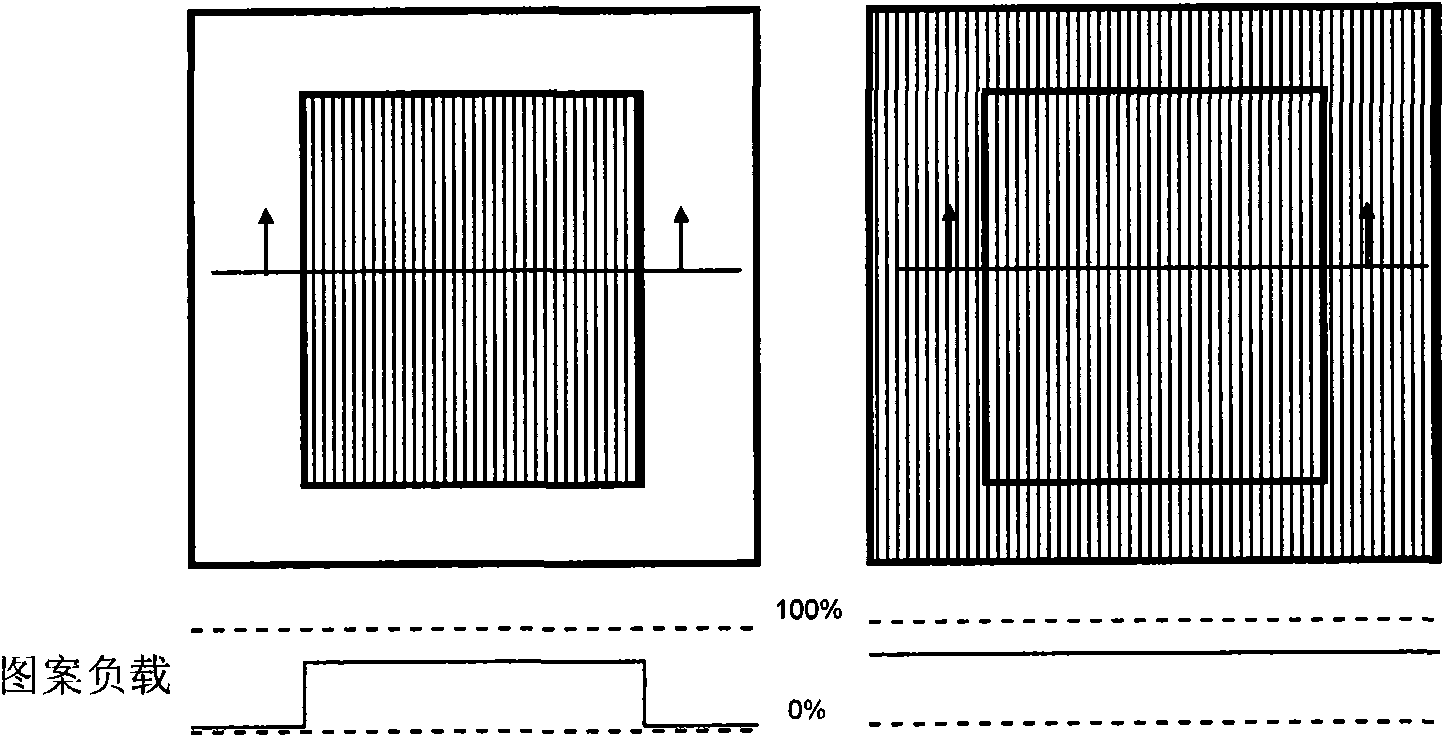

[0027] Figure 4 A schematic diagram of the principle of the solution of the present invention is shown. 401 is the main graphic to be transferred to the wafer, with a certain graphic load; 402 is a graphic corresponding to the preset frame graphic data, and the graphic has a graphic load close to that of the graphic 401 . The scheme of the present invention combines 401 and 402 to generate a photomask 403. The main pattern area of the photomask 403 has a figure as shown in 401, and the border area has a figure as shown in 402, so that the figure on the edge of the pattern area The load will not change drastically.

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further elaborated below in conjunction with specific examples.

[0029] Embodiment 1 of the present invention proposes a method for manufacturing a photomask. Various types of frame pattern data are prepared in advance. The fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com