Novel infant formula milk powder with optimized fat composition and preparation method thereof

A technology of infant formula and fat, applied in dairy products, whey, application, etc., can solve problems such as low cognitive score, achieve the effect of narrowing the gap and high similarity evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention also provides a method for preparing novel infant formula milk powder with optimized fat composition, comprising the following steps:

[0037] (1) Accept milk and standardize it;

[0038] (2) Milk, lactose, desalted whey powder, whey protein concentrate, prebiotics, baby vitamin premix, baby mineral premix, choline chloride and taurine are mixed evenly and completely dissolved to obtain the material Liquid A;

[0039] (3) Mix and stir the breastmilk substitute fat and edible vegetable blending oil, raise the temperature to 40-50°C, mix it into the feed liquid A after melting, and mix evenly to obtain the feed liquid B;

[0040] (4) Homogenize the obtained material liquid B, sterilize, concentrate, and spray dry to obtain material C;

[0041] (5) Mix material C with docosahexaenoic acid DHA, arachidonic acid ARA, nucleotides and lutein to get it. The mixing temperature is 25-30°C. The relative humidity is 40% to 50%;

[0042] (6) Store in compos...

Embodiment 1

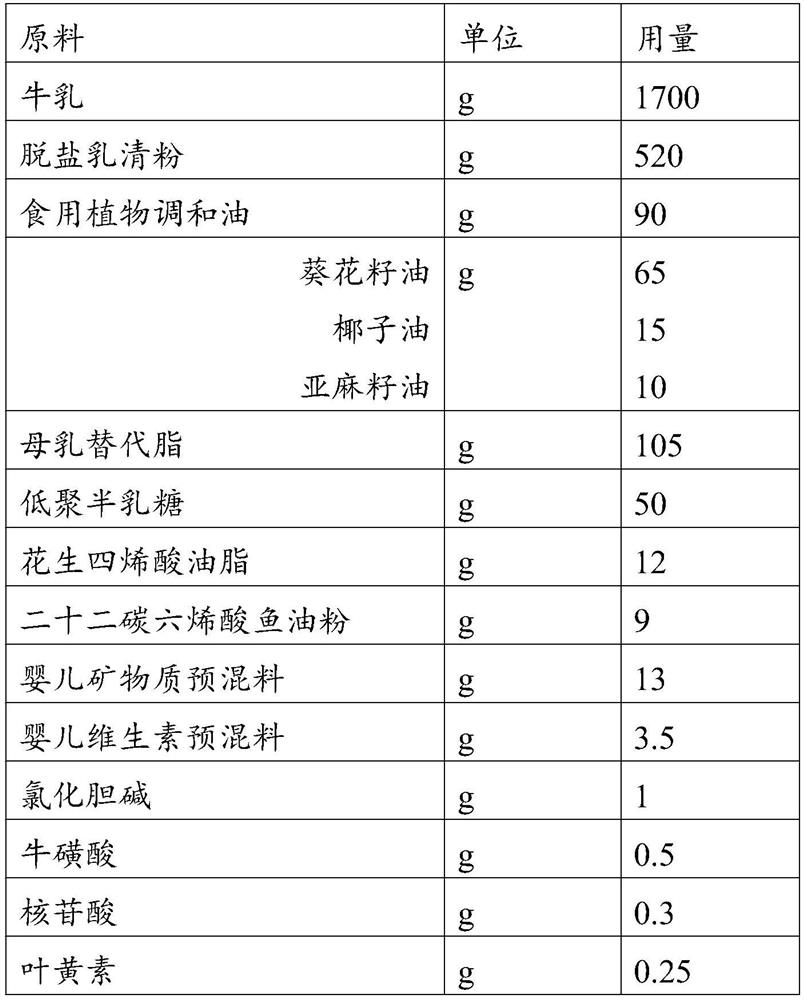

[0051] Formula of infant formula milk powder (calculated per 1000 grams of milk powder)

[0052]

[0053] Preparation:

[0054] (1) Accept milk and standardize it;

[0055] (2) Mix cow's milk, desalted whey powder, galacto-oligosaccharide, baby vitamin premix, baby mineral premix, choline chloride, and taurine in a batching tank and dissolve them completely to obtain a feed liquid A, the temperature is controlled at 40°C, and the mixing time is 15 minutes;

[0056] (3) Mix breast milk substitute fat and edible vegetable blending oil into the oil tank and start the agitator, heat up to 40°C, mix it into feed liquid A after melting, and mix evenly to obtain feed liquid B;

[0057] (4) Homogenize the obtained material liquid B at 15MPa, 50°C, sterilize at 80°C for 40 seconds, concentrate, and use pressure spray drying to obtain material C. The feed temperature of the pressure spray dry is 65°C, and the inlet air temperature The temperature is 150°C, the exhaust air temperat...

Embodiment 2

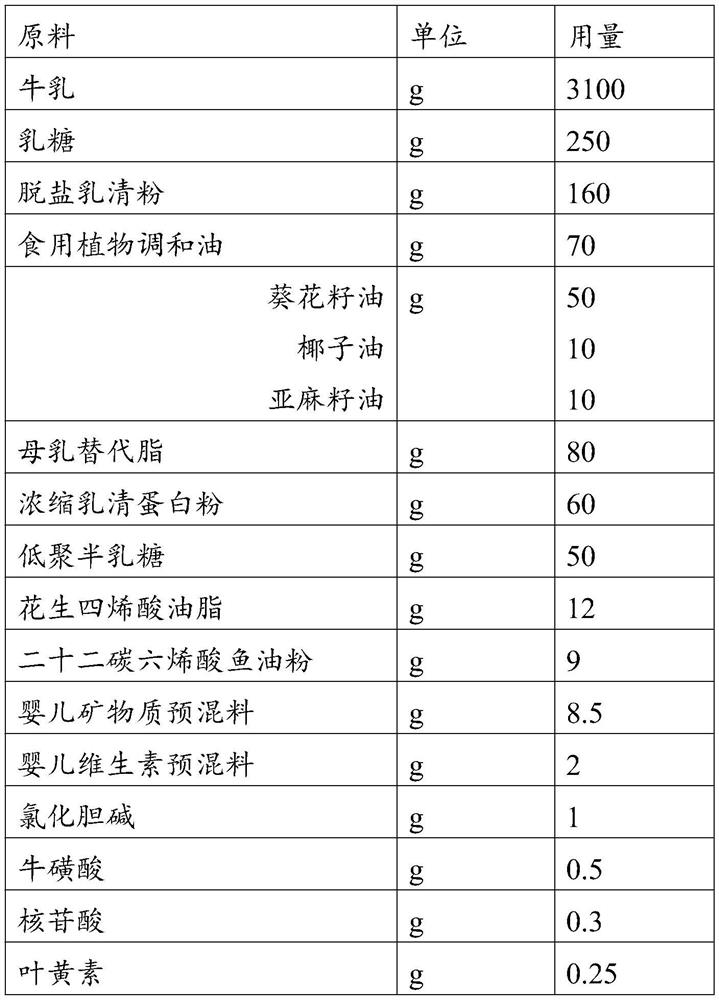

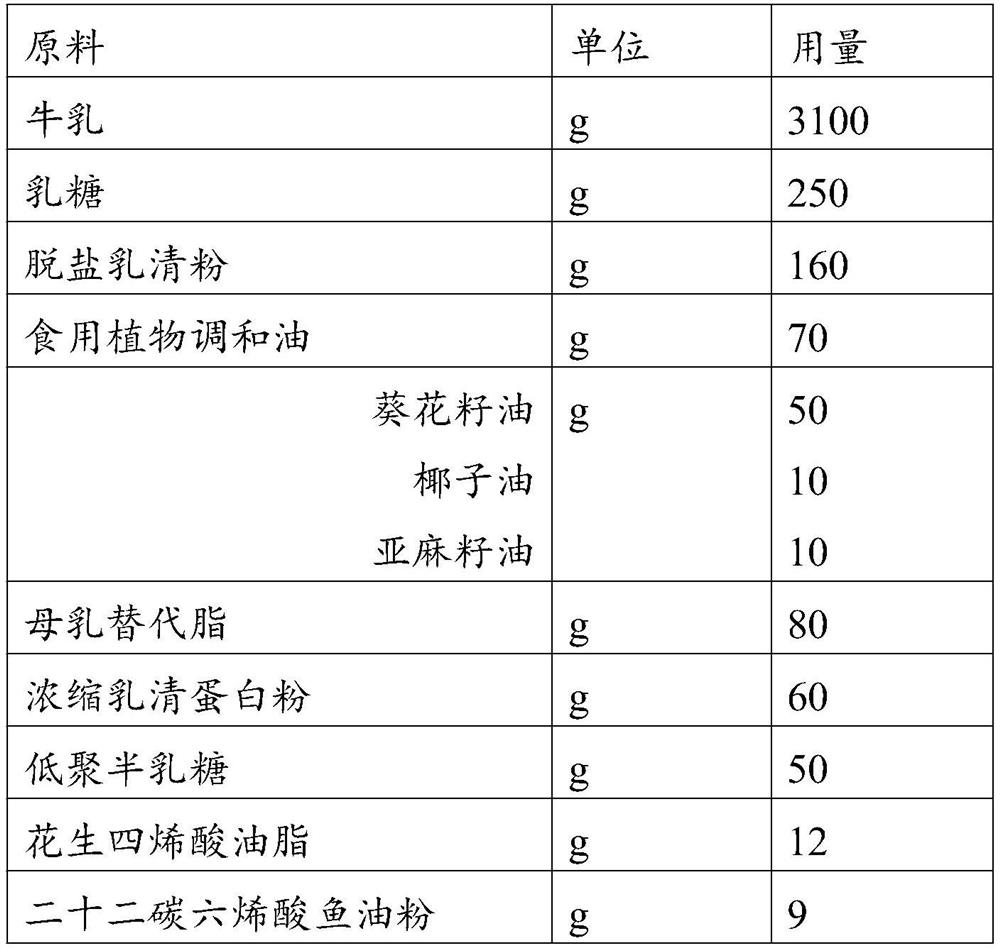

[0061] Formula of infant formula milk powder (calculated per 1000 grams of milk powder)

[0062]

[0063] Preparation:

[0064] (1) Accept milk and standardize it;

[0065] (2) Milk, lactose, desalted whey powder, whey protein concentrate, galacto-oligosaccharides, infant vitamin premix, infant mineral premix, choline chloride, and taurine are mixed uniformly in the batching tank. Completely dissolve to obtain material liquid A, the temperature is controlled at 30°C, and the mixing time is 10 minutes;

[0066] (3) Mix breastmilk substitute fat and edible vegetable blending oil into the oil tank and start the agitator, heat up to 50°C, mix it into feed liquid A after melting, and mix evenly to obtain feed liquid B;

[0067] (4) Homogenize the obtained material liquid B at 20MPa, 55°C, sterilize at 85°C for 35 seconds, concentrate, and use pressure spray drying to obtain material C. The feed temperature of the pressure spray dry is 70°C, and the inlet air temperature The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com