Intelligent horizontal lollipop heat sealing twist packaging system

A packaging system and horizontal technology, applied in the field of intelligent horizontal lollipop heat-sealing and kink packaging system, can solve the problems of high labor intensity, poor sanitary conditions, poor sanitary conditions, etc., so as to reduce labor intensity and ensure work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

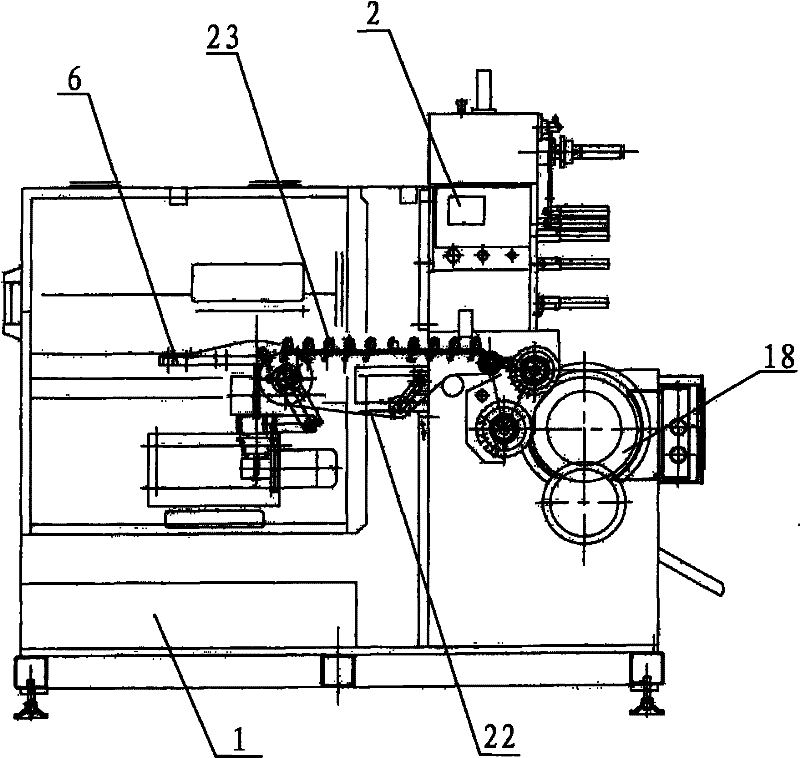

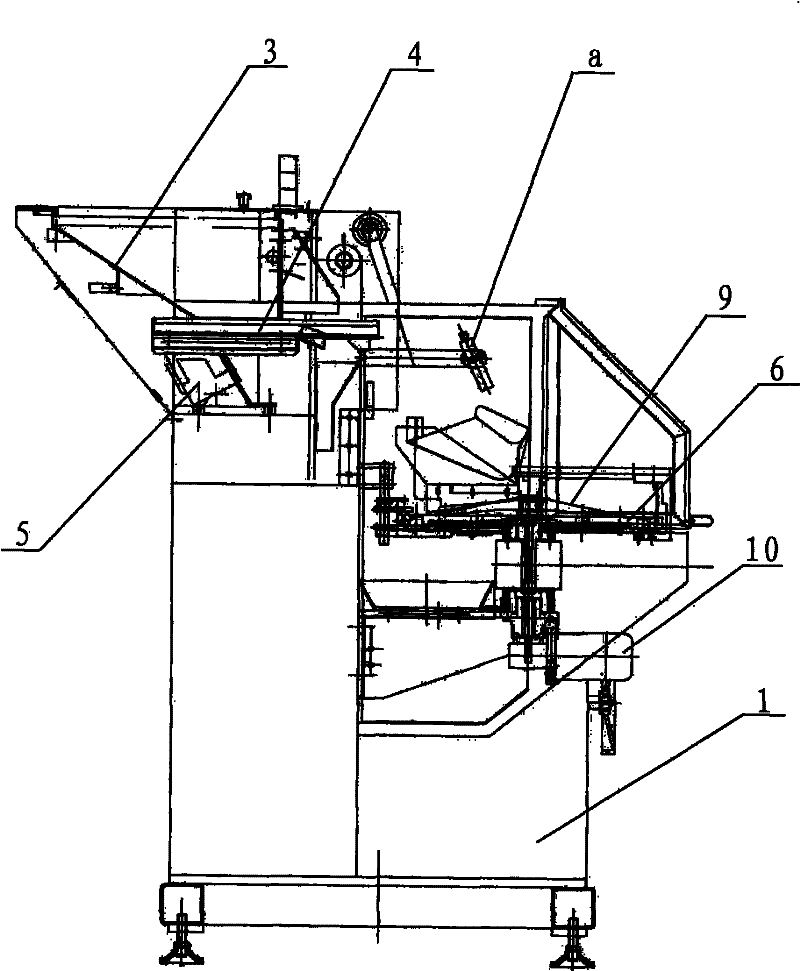

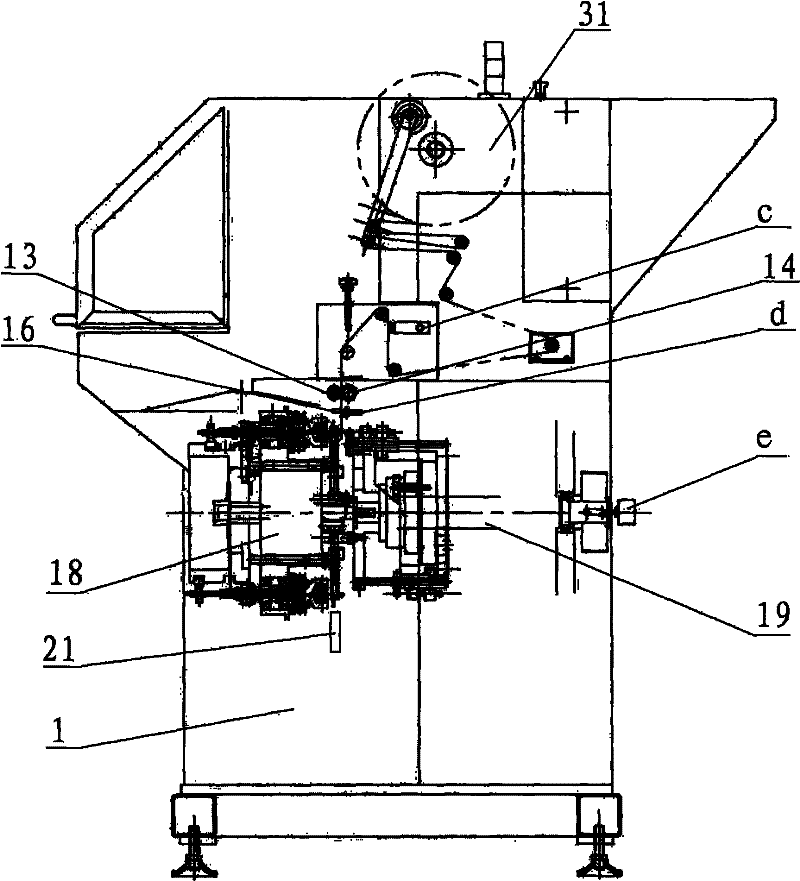

[0020] like figure 1 , 2 , 3, the present invention includes a rack 1, a control system 2, and also includes an automatic sugar feeding mechanism located at the upper part of the rack, see figure 2 : Including sugar hopper 3, vibrating sugar pan 4, electromagnetic oscillator 5 and photoelectric switch a, sugar hopper 3 is arranged on the upper part of rack 1, and is a conical structure with an opening at the bottom, and the bottom opening is located above the shaking sugar pan 4, which shakes the sugar pan. 4. An electromagnetic oscillator 5 is installed at the bottom, and the photoelectric switch a is arranged in front of the lower sugar mouth of the shaking sugar tray 4, and is located directly above the sugar management mechanism. It is used to detect the stacking thickness of the lollipops in the sugar management tray 6. The electromagnetic oscillator 5 is connected to the control system 2;

[0021] The sugar handling mechanism located in the middle of the left side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com