Method for purifying and ageing wine

A technology of aging and aging agent, which is applied in the preparation of alcoholic beverages, etc., can solve the problems of long time and achieve the effects of simplifying the production process, speeding up the aging process, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

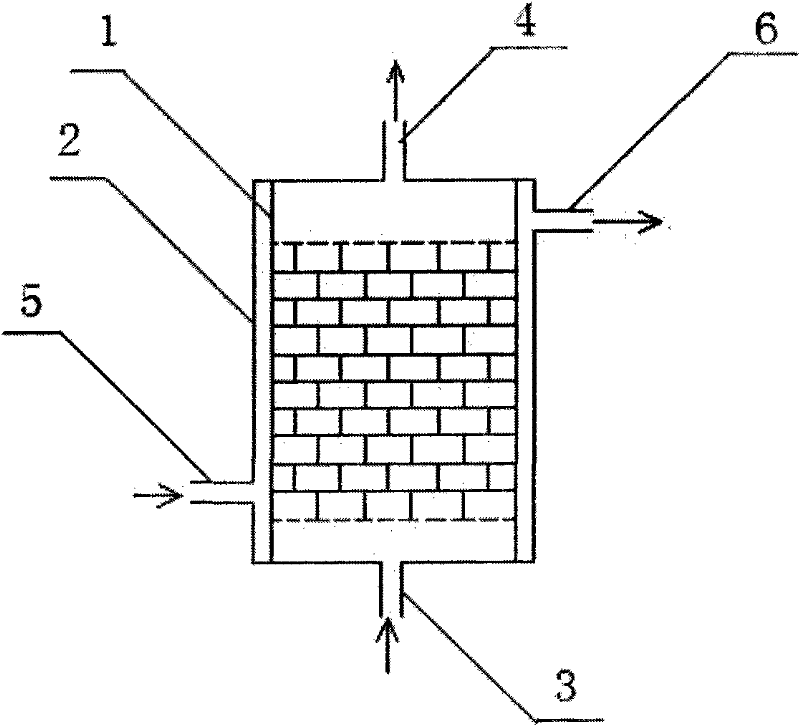

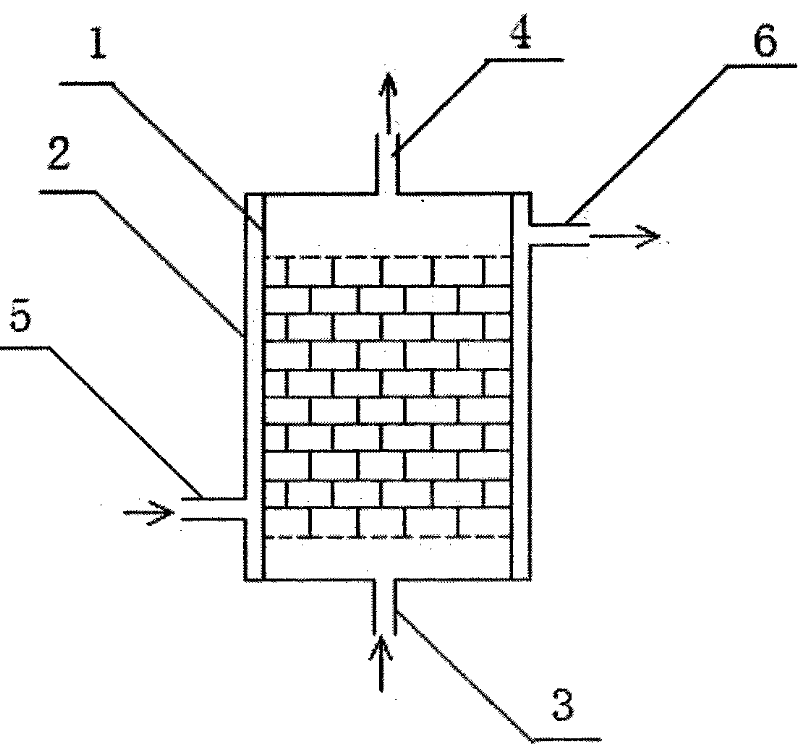

Image

Examples

Embodiment 1

[0016] Example 1: The attapulgite-based purification aging agent is placed in a cylindrical maturation cylinder with a jacket; warm water is passed into the jacket to ensure that the contact temperature between the wine and the attapulgite-based purification aging agent is 20°C; It enters from the bottom of the cylinder and flows out from the top of the cylinder. The contact time between the wine and the attapulgite-based purification aging agent in the cylinder is 8 minutes. The analysis of gas chromatography and GC-MS showed that the chromatographic skeleton composition of the wine processed by the method of the present invention is significantly different from the corresponding pure liquor, and it is basically the same as the skeleton composition of the same type wine that has been stored for 10 years; at the same time, the wine taster After tasting, it was found that the taste and aroma of the processed wine were basically the same as those of the same type that had been in ...

Embodiment 2

[0017] Example 2: The attapulgite-based purification aging agent is placed in a cylindrical maturation cylinder with a jacket; warm water is passed into the jacket to ensure that the contact temperature between the wine and the attapulgite-based purification aging agent is 30°C; It enters at the bottom of the cylinder and flows out from the top of the cylinder. The contact time between the wine and the attapulgite-based purification aging agent in the cylinder is 5 minutes. The analysis of gas chromatography and GC-MS showed that the chromatographic skeleton composition of the wine processed by the method of the present invention is obviously different from the corresponding pure liquor, and it is basically the same as the skeleton composition of the same type wine that has been stored for 15 years; at the same time, the wine taster After tasting, it was found that the taste and aroma of the processed wine were basically the same as those of the same type wine in the cellar for ...

Embodiment 3

[0018] Example 3: The attapulgite-based purification aging agent was placed in a cylindrical maturation cylinder with a jacket; warm water was passed into the jacket to ensure that the contact temperature between the wine and the attapulgite-based purification aging agent was 10°C; The bottom of the cylinder enters and flows out from the top of the cylinder. The contact time between the wine and the attapulgite-based purification aging agent in the cylinder is 10 minutes. The analysis of gas chromatography and GC-MS showed that the chromatographic skeleton composition of the wine processed by the method of the present invention is obviously different from the corresponding pure liquor, and it is basically the same as the skeleton composition of the same type wine that has been stored for 5 years; at the same time, the wine taster After tasting, it was found that the taste and aroma of the processed wine were basically the same as those of the same type wine in the cellar for 5 y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com