Laser restoring method of aircraft engine cylinder body

An aircraft engine and laser repair technology, applied in the field of laser repair, can solve the problems of irreparable, deep depth and high production cost, and achieve the effects of dense cladding layer and interface structure, improved wear resistance and fine grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

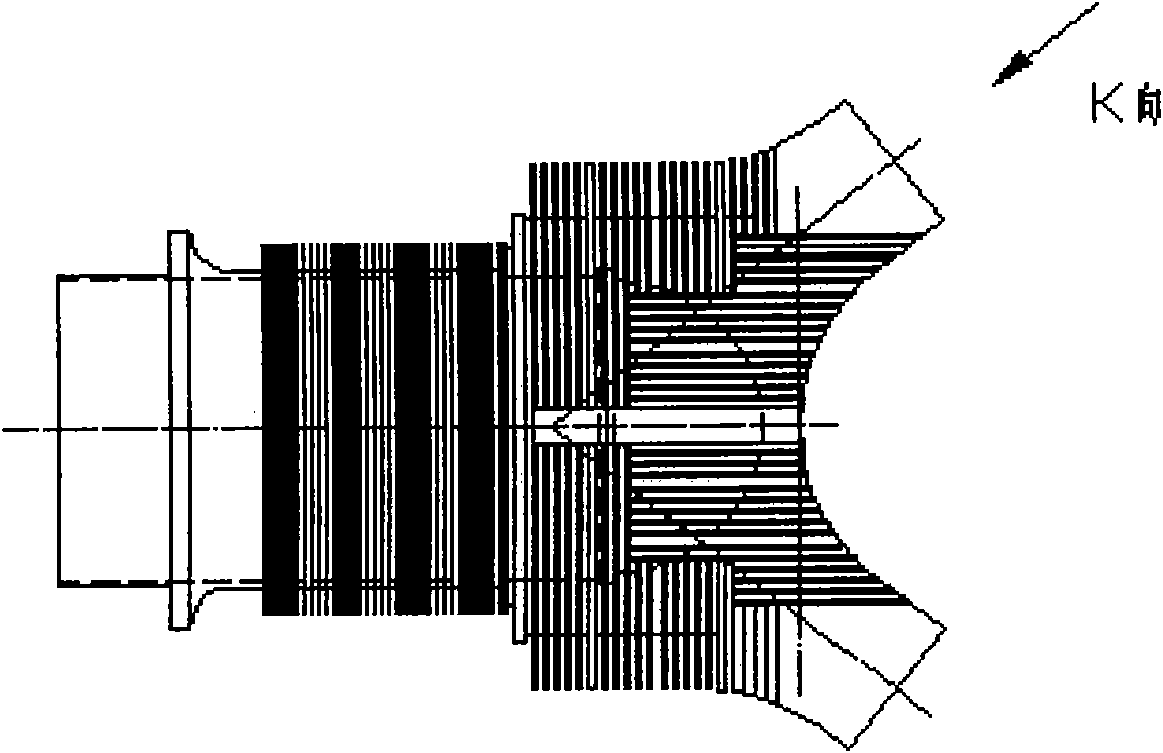

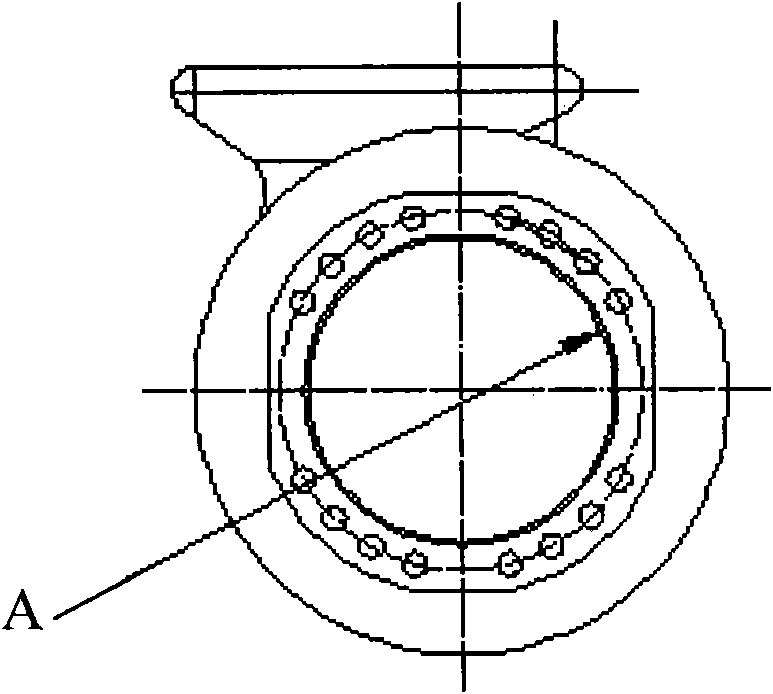

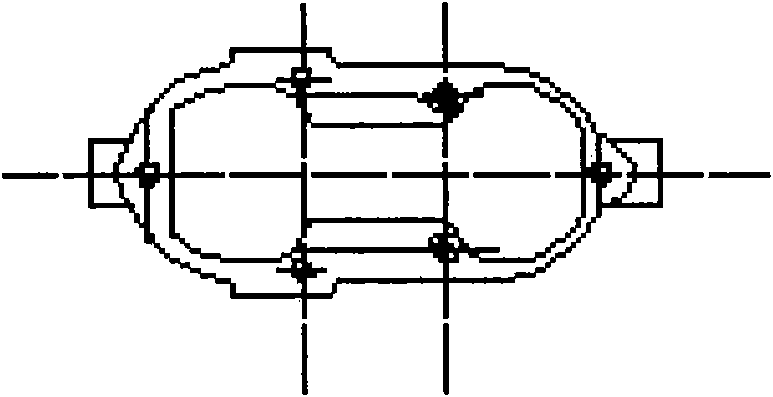

[0015] It can be seen from the drawings that when the inner cavity A of the aircraft engine cylinder block is unusable due to wear, a specific laser process can be used for cladding at this time, so that the worn part can be repaired, and then its geometric size can be restored by machining without Heat treatment results in a reusable engine block. The specific repair method is as follows:

[0016] (1) Use mechanical processing to remove the fatigue layer on the parts to be repaired in the inner cavity of the cylinder to reach a state suitable for laser repair, and then carry out coloring flaw detection to ensure that the fatigue layer is completely removed;

[0017] (2) Prepare the alloy powder, the particle size of the alloy powder is 50-150 μm, the composition (wt%) is: C: 0.1-0.2, Cr: 14-20, Ni: 2-6, Mn: 0-1.5, Mo: 0.5~1.5, W: 0~2.5, Si: 1.5~2.5, B: 2.0~3.0, the rest is Fe;

[0018] (3) Use the focusing lens to guide the laser beam into the inner cavity of the cylinder, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com