Oil injection timing control policy of diesel engine double-swirl combustion system

A combustion system and fuel injection timing technology, applied in fuel injection control, engine control, electrical control, etc., can solve problems such as improper matching, matching relationship between double swirl combustion chambers at the start of fuel injection, and combustion deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

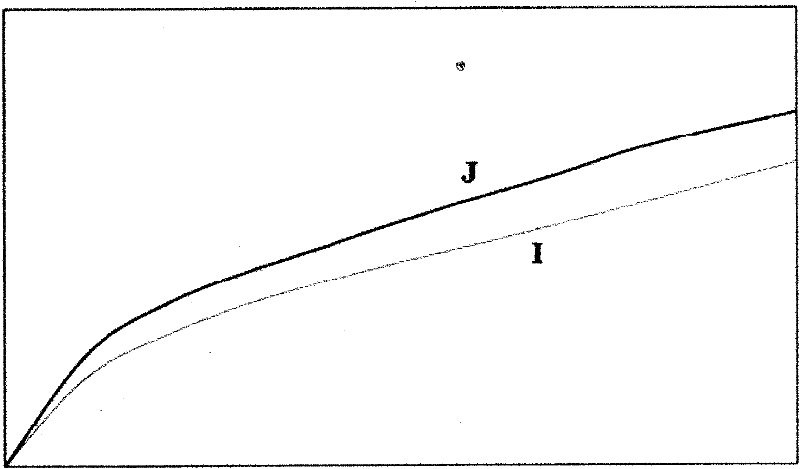

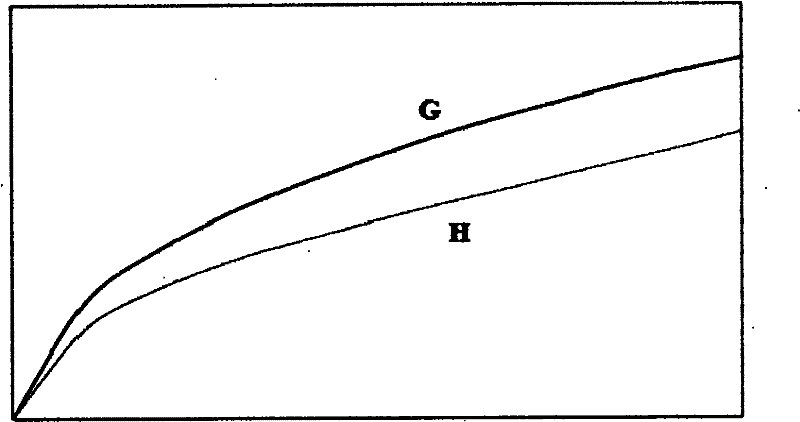

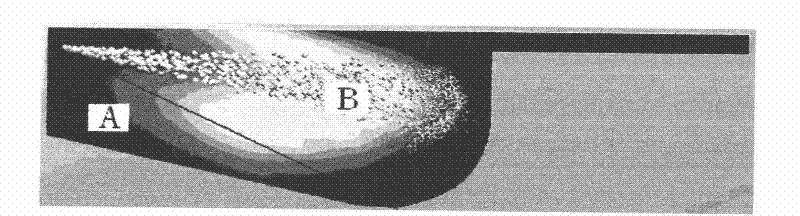

[0019] The fuel injection timing control strategy under the double plume combustion system is divided into two parts in the implementation process, one part is to determine the relative installation position between the fuel injector and the double plume combustion chamber, and the other part is to control the fuel injection timing through electronic fuel injection. The system determines the injection start point.

[0020] Due to the high requirements for the cooperation between the fuel jet and the shape of the combustion chamber in the double-plume combustion system, there are also high requirements for the installation position of the injector in the double-plume combustion system. Therefore, when designing the double-plume combustion system, the relative installation position between the injector and the double-plume combustion chamber should be determined first to ensure that the distribution ratio of the oil beam between the inner chamber and the outer chamber is 1:9.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com