Metal plate defect online detection method and device

A detection method and metal plate technology, applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve problems such as interference, failure to display images, and inability to detect unpenetrated holes in the steel plate to achieve anti-interference Strong, accurate detection data effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

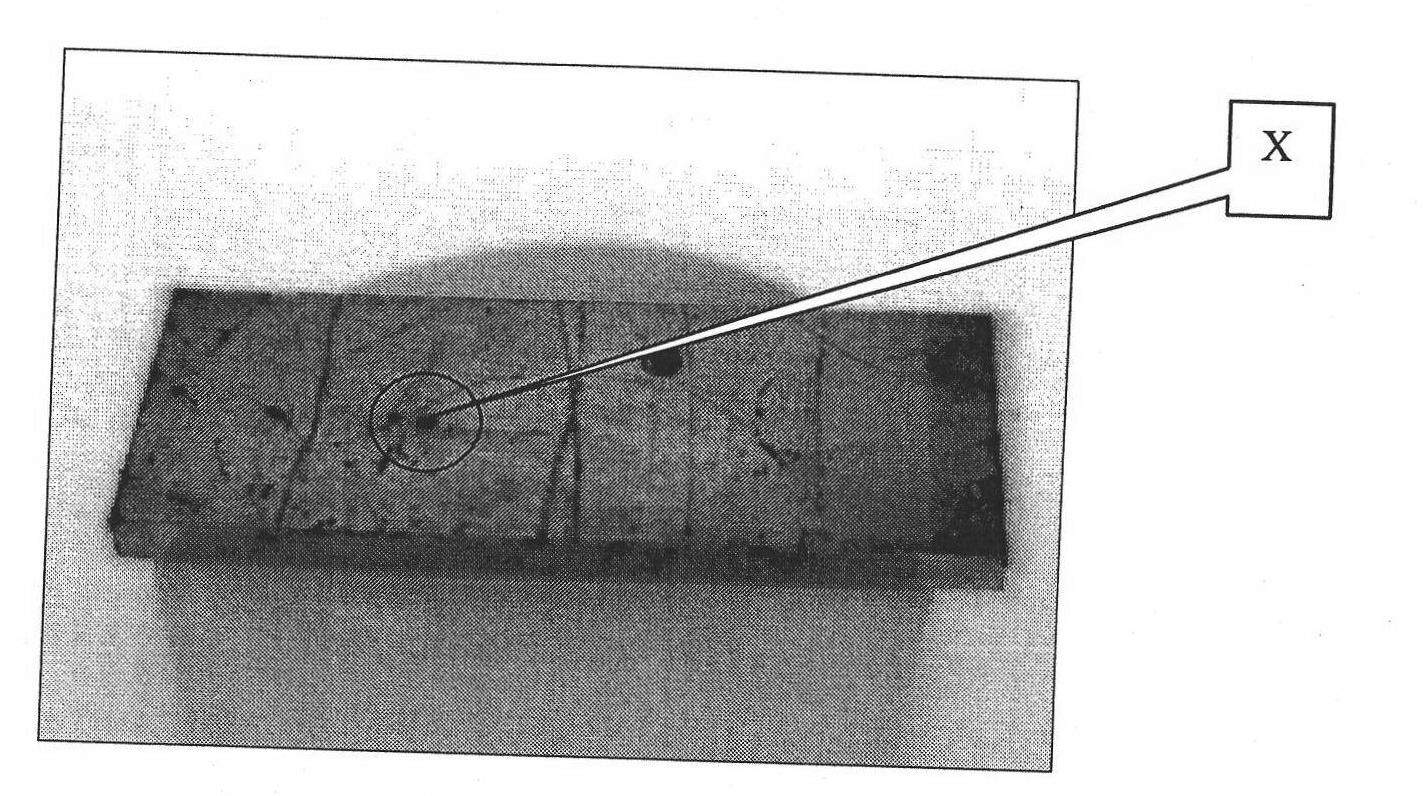

[0052] On-line detection method for metal plate defects, according to Figure 4 Process arrangement shown. The metal plate 1 to be detected is a hot steel plate at a high temperature of 190-250° C. which is being horizontally sent out on the conveying line during the hot rolling process.

[0053] The selected metal plate online detection device includes: a device 3 for spraying or blowing refrigerant on the top surface of the detected metal plate 1 (specifically, it can be a cold water, cold air nozzle or refrigerant nozzle with a control valve), According to the forward direction A of the metal plate, the thermal imager 4 and the thermal imager 6 (both select the infrared thermal imager manufactured by Keyi Company or Rhine Technology Co., Ltd.) before and after the nozzle or set up, and a timer control function Digital program control device 5 (specifically, it can be realized by computer). The three are connected, and according to the traveling speed of the metal plate, t...

Embodiment 2

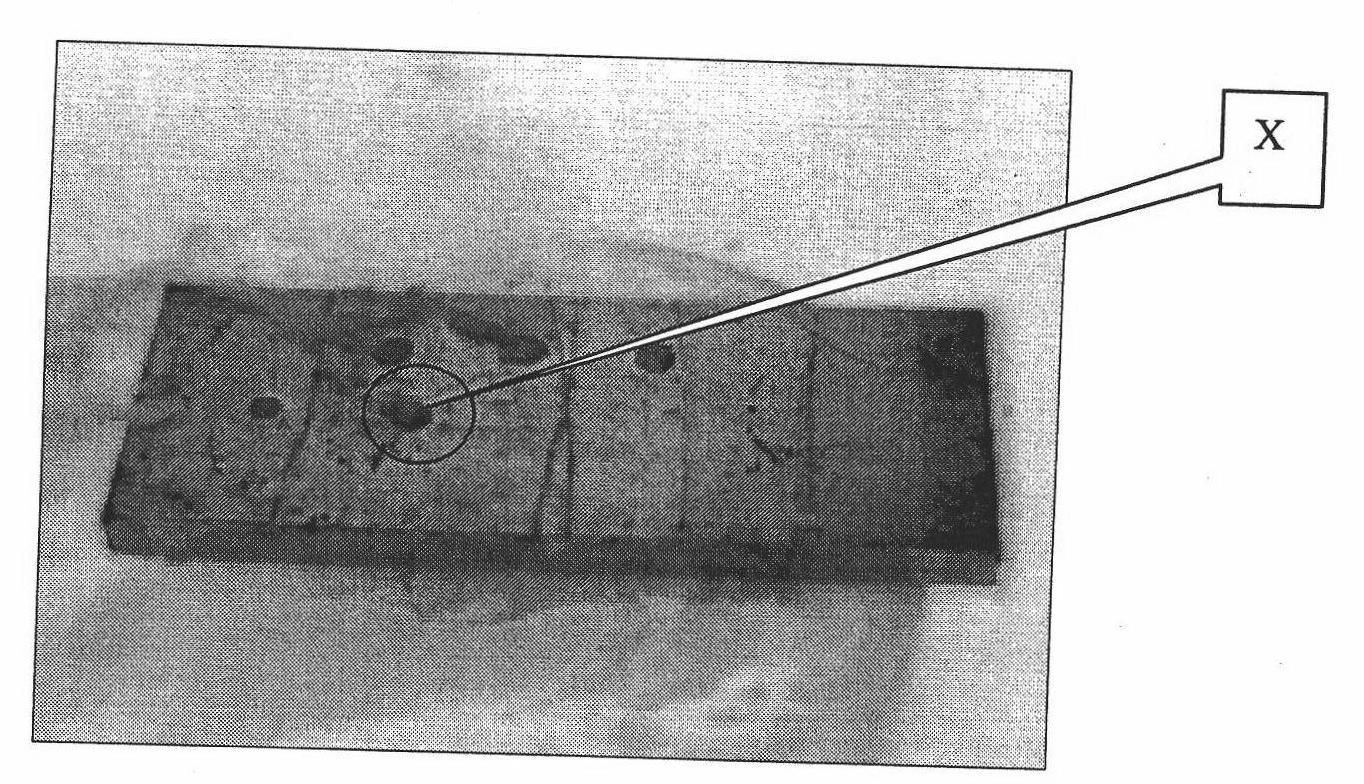

[0055] On-line detection method for metal plate defects, according to Figure 5 Process arrangement shown. The metal plate 1 to be tested is a hot steel plate at a high temperature of 200-210°C that is being horizontally sent out on the conveyor line during the hot rolling process. The device 3 suddenly sprays cold water on the metal plate to cool down to 185°C; c, pre-installs an infrared thermal imager 4 above the metal plate to be tested, and sprays the cold water on the metal plate to cool down in a short period of time after the instantaneous cooling. After a period of time, the real-time infrared thermal image is taken; d, when the temperature of the metal plate returns to about 200°C, use another infrared thermal imager 6 to take another picture of the part of the metal plate that has been sprayed with cold water to cool down; e, compare the two before and after The thermal images taken by two infrared thermal imaging cameras on the same area of the metal plate, the ...

Embodiment 3

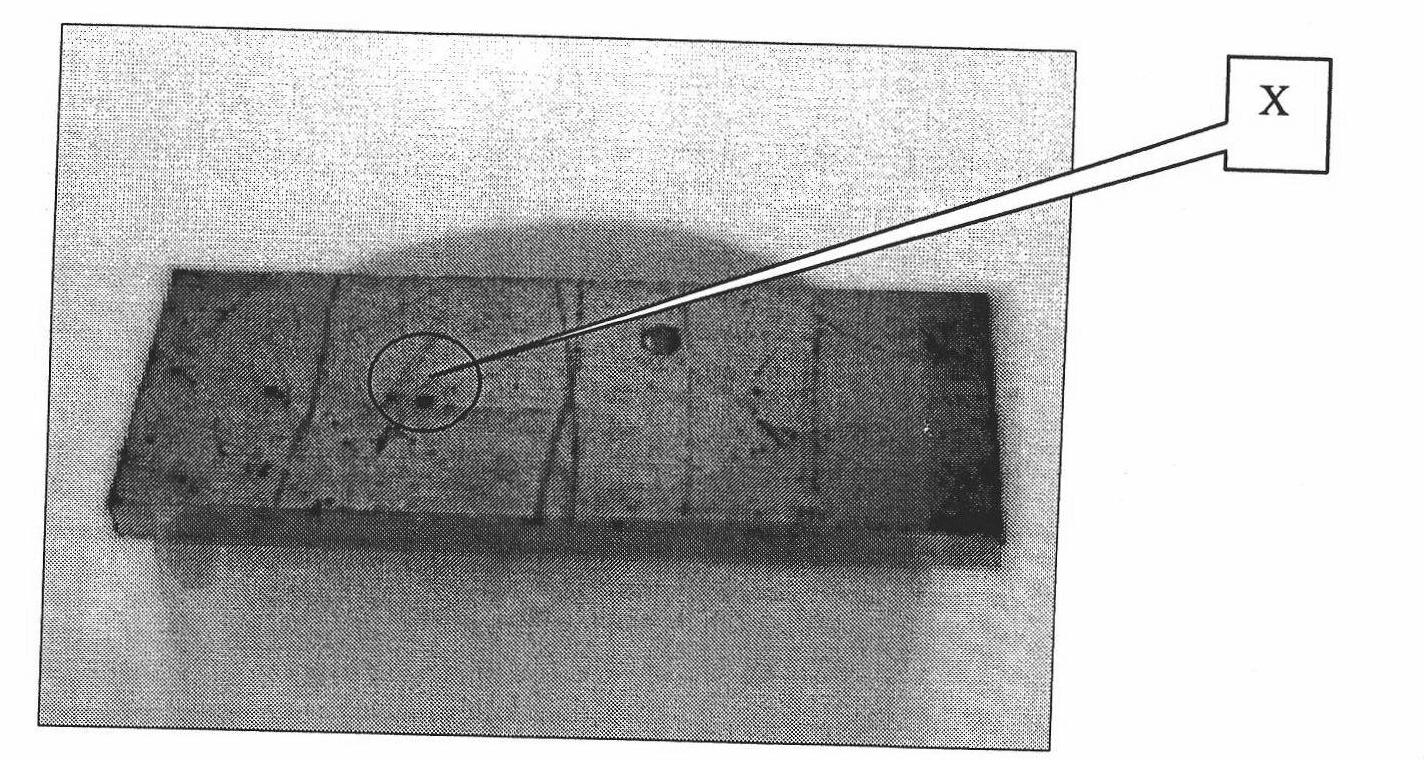

[0058] On-line detection methods for metal plate defects, such as Figure 6 As shown, the following steps are included: a. Make the metal plate to be tested at a high temperature (1000° C.) and stagnate or move slowly (relative to the infrared thermal imager of high-speed camera, which is almost stationary); b. Using the metal plate to be tested An infrared thermal imager installed above takes pictures of the metal plate in real time; c. Use a spraying device to suddenly spray cold water on the metal plate to cool down to about 900°C in the area corresponding to the photographed metal plate; d . Use the same infrared thermal imager to quickly take infrared thermal images of the cooling area of the metal plate when the water vapor is gone; e. Compare the two infrared thermal images before and after the same infrared thermal imager. If there is an abnormal defect image, it indicates that there are defects including through holes at this position; if there is no abnormal defect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com