Manufacturer advanced service system for NC (numerical control) processing center

A service system and manufacturer's technology, applied in the direction of program control devices, etc., can solve the problem that the operation interface cannot meet the more and more professional needs of users

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

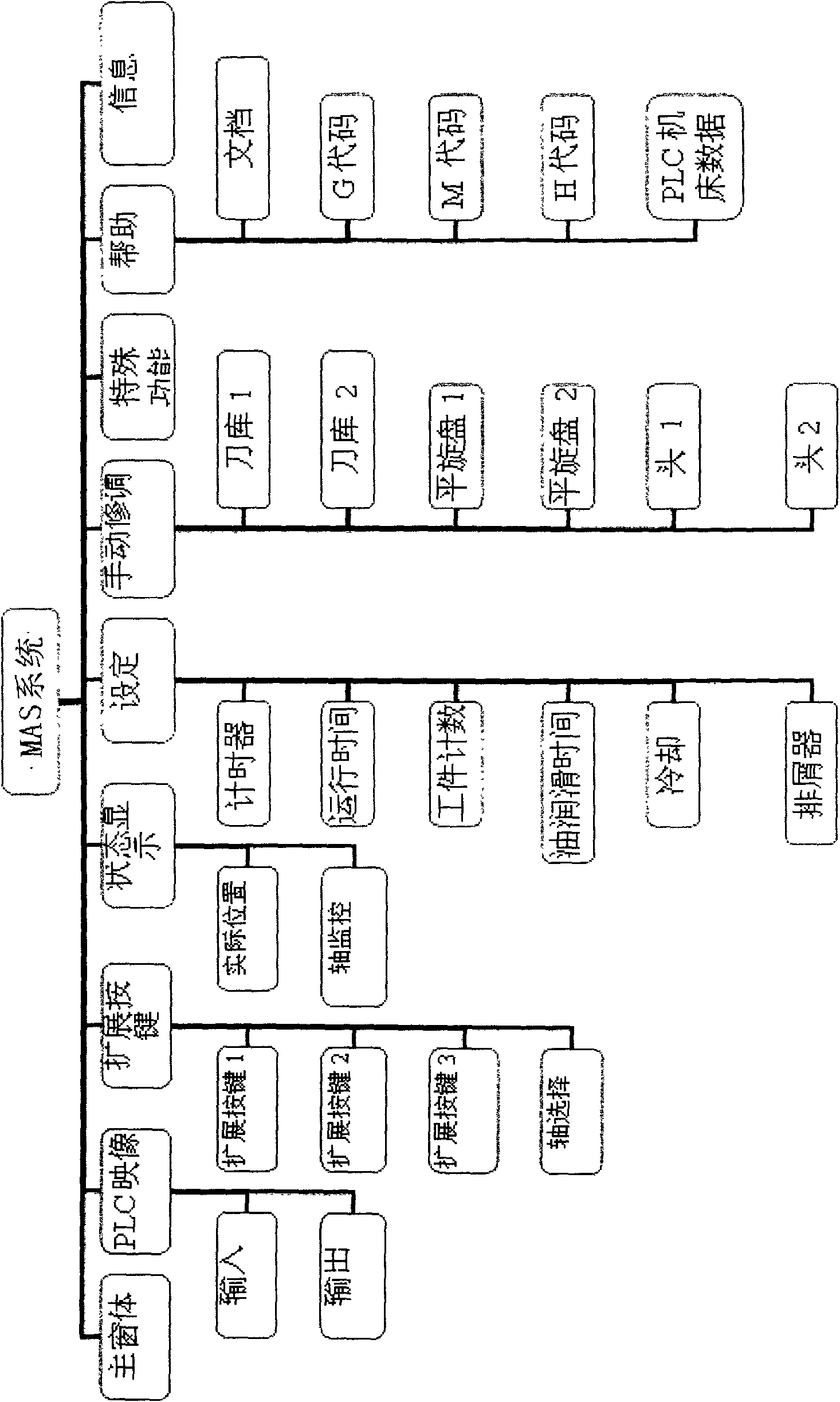

[0029] The present invention is used for the high-level service system of the manufacturer of the CNC machining center control system, based on NC, PLC, HMI of Siemens 840D, it is characterized in that the development of the whole project is completed according to the following measures,

[0030] 1. Project development process:

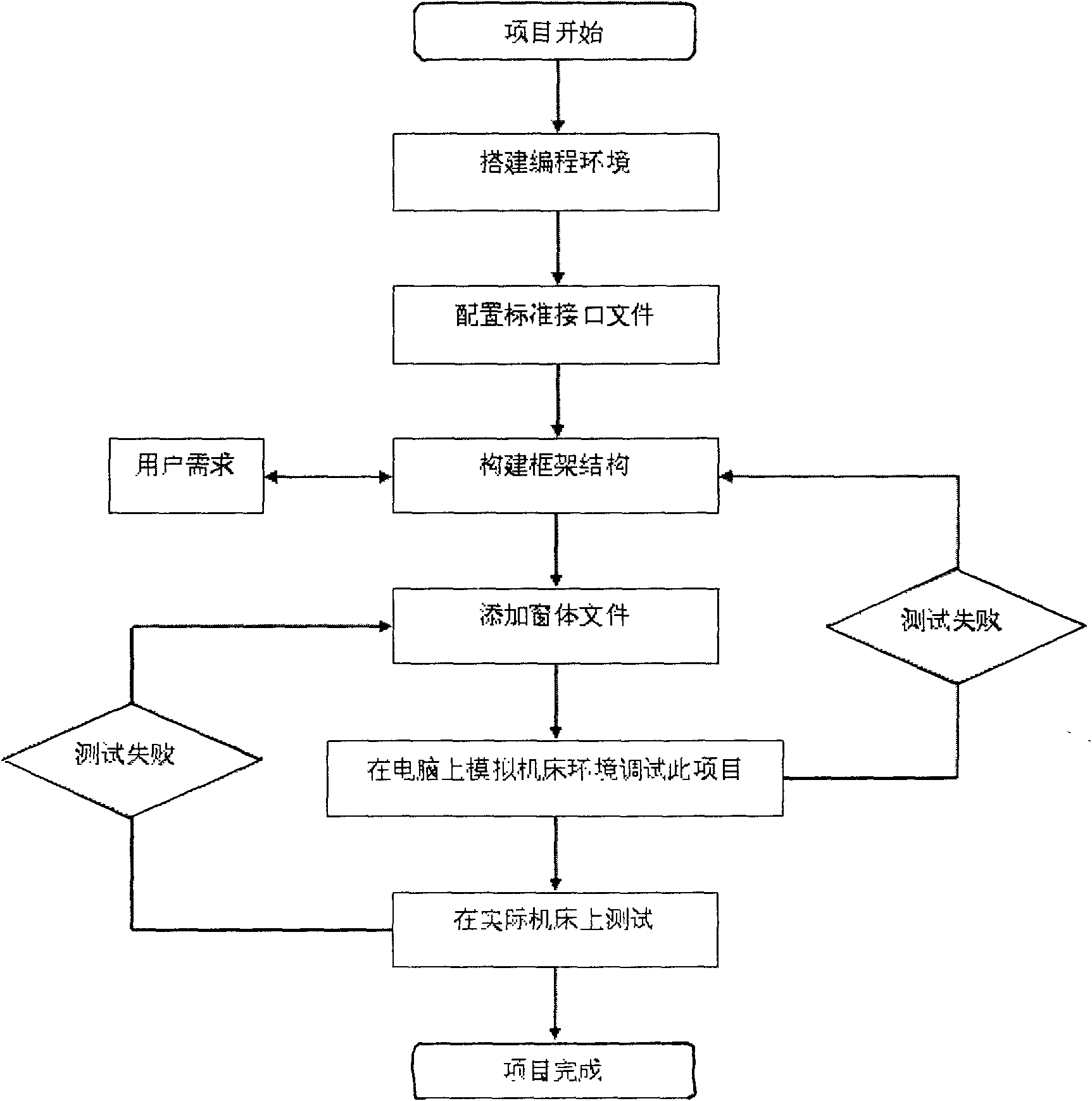

[0031] The advanced manufacturer service system of the present invention, according to demand analysis, coordinates the overall structure, feasibility and project cycle of the project, such as figure 1 :

[0032] 1) Build a programming environment: install English version VB6.0, English version VC++6.0, OEM programming package, Advanced HMI simulator.

[0033] 2) Configure standard interface files: configure VB6.0, VC++6.0 programming environment, modify REGIE.INI system boot file, mmc2.ini file, add *.ZUS and *.MDI files, add *.dll language management files, The interface button files RE_UK.ini. and RE_CH.ini assign the position sequence of each fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com