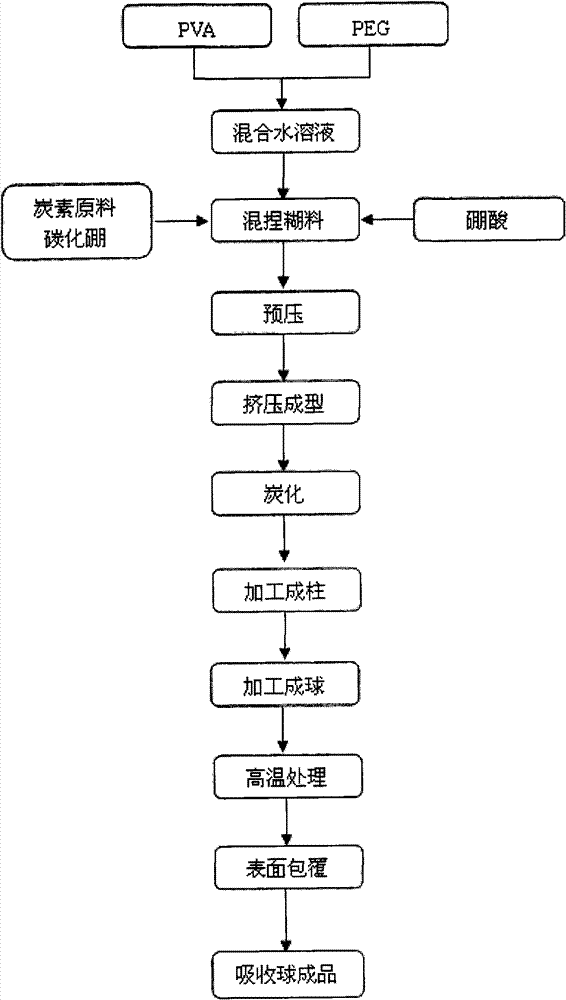

Neutron absorption ball preparation method

A technology of absorbing balls and neutrons, applied in the field of nuclear reactors, to achieve the effects of easy cracking and discharge, high purity of PVA, and low equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

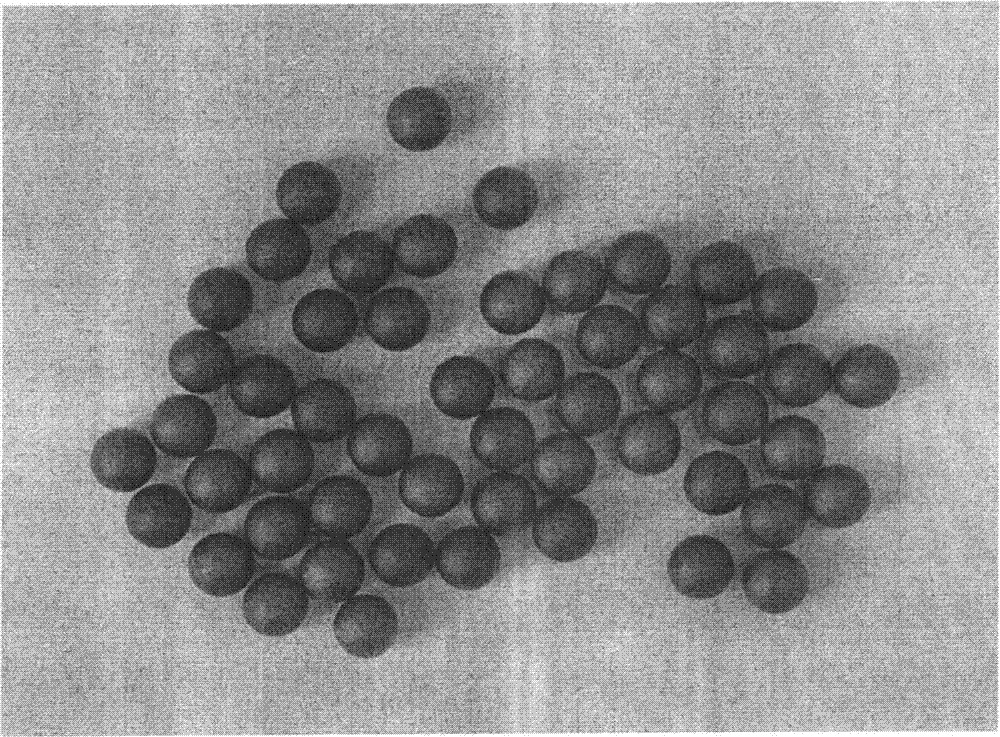

Embodiment 1

[0030] Weigh 55Kg of natural graphite, 20Kg of carbon black, and 25Kg of boron carbide. A mixed aqueous solution of PVA and PEG is prepared, the concentration of the mixed aqueous solution is 10 wt%, wherein the mass ratio of PVA:PEG is 4:1. Add the weighed powder into the mixed aqueous solution, the mass ratio is 2:3, knead in the kneader for 1 hour, the kneading temperature is 80°C, then add 2Kg of boric acid, continue kneading for 3 hours, and make it available for extrusion molding of paste. Put the obtained paste into an SL65B extrusion molding machine for pre-compression, pressurize at 350MPa, and hold the pressure for 5 minutes. After pre-compression, a rod with a diameter of 10.5 mm is extruded on the extruder, and the extrusion pressure is 300 MPa. The bar is carbonized under the protection of nitrogen, the temperature is raised to 800°C at 4°C per minute, kept for 4 hours, and the temperature is naturally lowered. Bar stock is cut into small columns that are appro...

Embodiment 2

[0032] Weigh 55Kg of natural graphite, 30Kg of carbon black, and 15Kg of boron carbide. A mixed aqueous solution of PVA and PEG is prepared, the concentration of the mixed aqueous solution is 10 wt%, wherein the mass ratio of PVA:PEG is 4:1. Add the weighed powder into the mixed aqueous solution, the mass ratio is 2:3, knead in the kneader for 1 hour, the kneading temperature is 60°C, then add 2Kg of boric acid, continue kneading for 2 hours, and make it available for extrusion molding of paste. Put the obtained paste into an SL65B extrusion molding machine for pre-compression, pressurize at 350MPa, and hold the pressure for 5 minutes. After pre-compression, a rod with a diameter of 10.5 mm is extruded on the extruder, and the extrusion pressure is 300 MPa. The bar is carbonized under the protection of argon, the temperature is raised to 1000°C at a rate of 3°C per minute, the temperature is kept for 3.5 hours, and the temperature is naturally lowered. Bar stock is cut into...

Embodiment 3

[0034] Weigh 50Kg of natural graphite, 25Kg of carbon black, and 25Kg of boron carbide. A mixed aqueous solution of PVA and PEG is prepared, the concentration of the mixed aqueous solution is 8wt%, wherein the mass ratio of PVA:PEG is 4:1. Add the weighed powder into the mixed aqueous solution, the mass ratio is 1:1, knead in the kneader for 1 hour, the kneading temperature is 20 ° C, then add 1.5Kg of boric acid, continue kneading for 2 hours, and make it available for extrusion Shaped paste. Put the obtained paste into an SL65B extrusion molding machine for pre-compression, pressurize at 300MPa, and hold the pressure for 8 minutes. After pre-compression, a rod with a diameter of 6.5 mm is extruded on the extruder, and the extrusion pressure is 250 MPa. The bar is carbonized under the protection of nitrogen, the temperature is raised to 900°C at a rate of 3°C per minute, the temperature is kept for 3 hours, and the temperature is naturally lowered. Bar stock is cut into sm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com