Cold-drawing die

A technology of drawing dies and drawing die sets, which is applied in the direction of wire drawing dies, etc., can solve the problems of inaccurate cross-bar twist spacing, heavy waste of talc powder, short service life, etc., and achieve smooth surface forming, high product quality and accurate spacing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

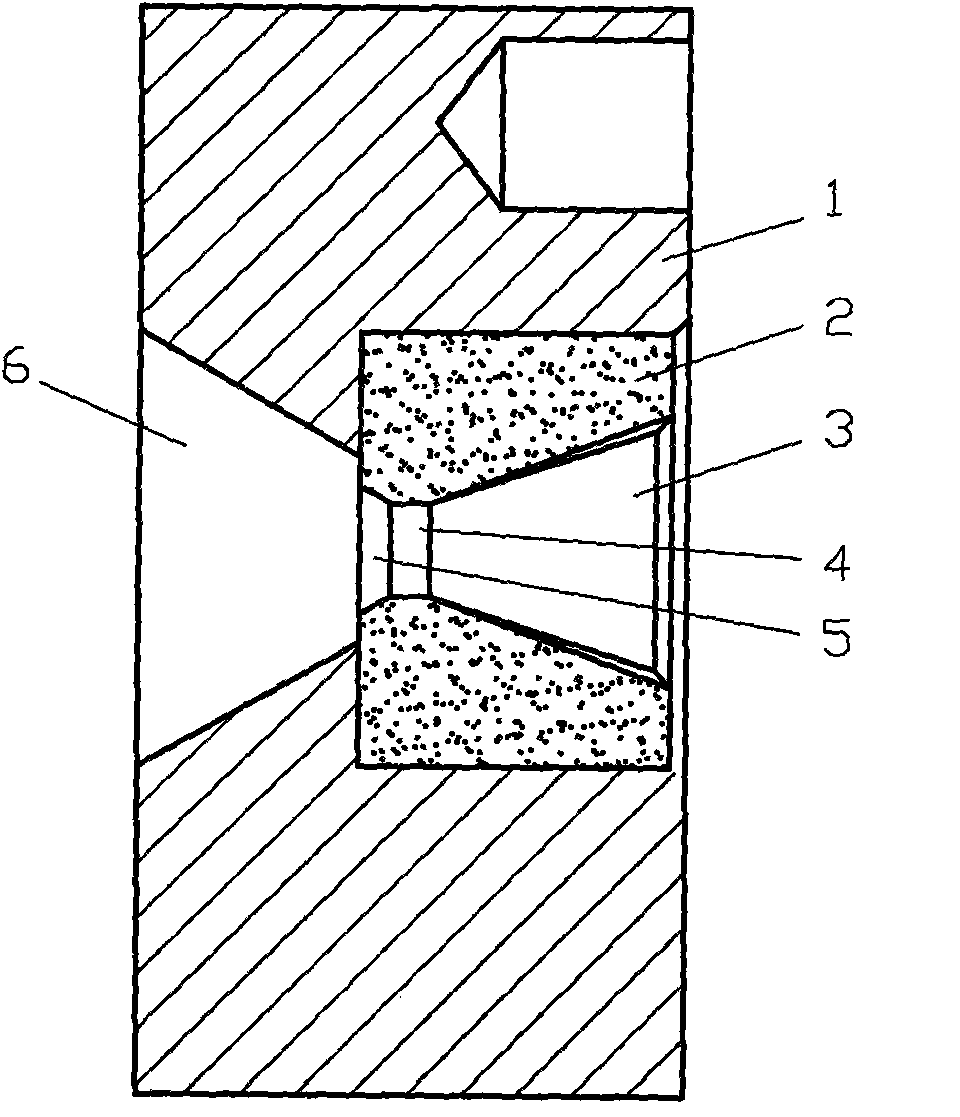

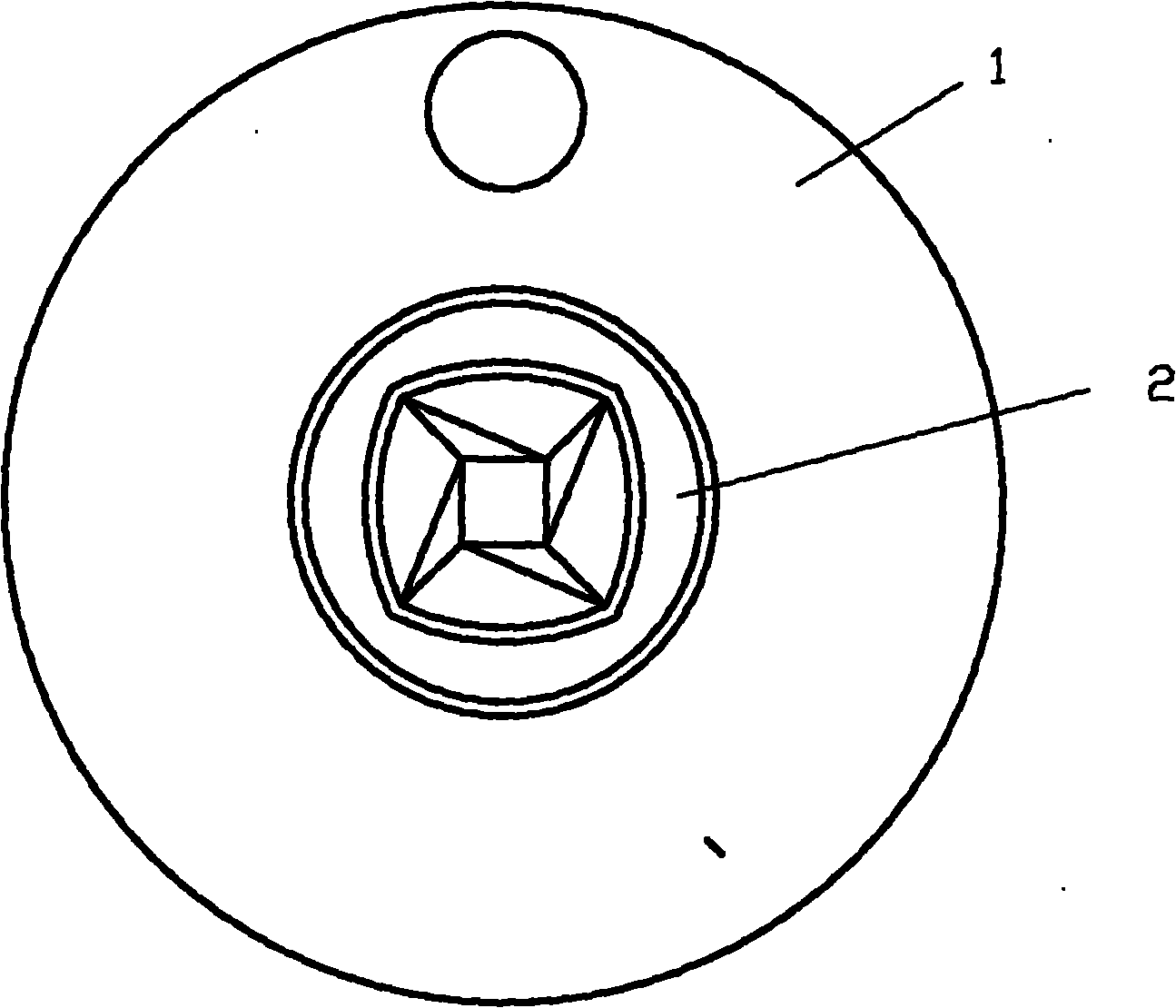

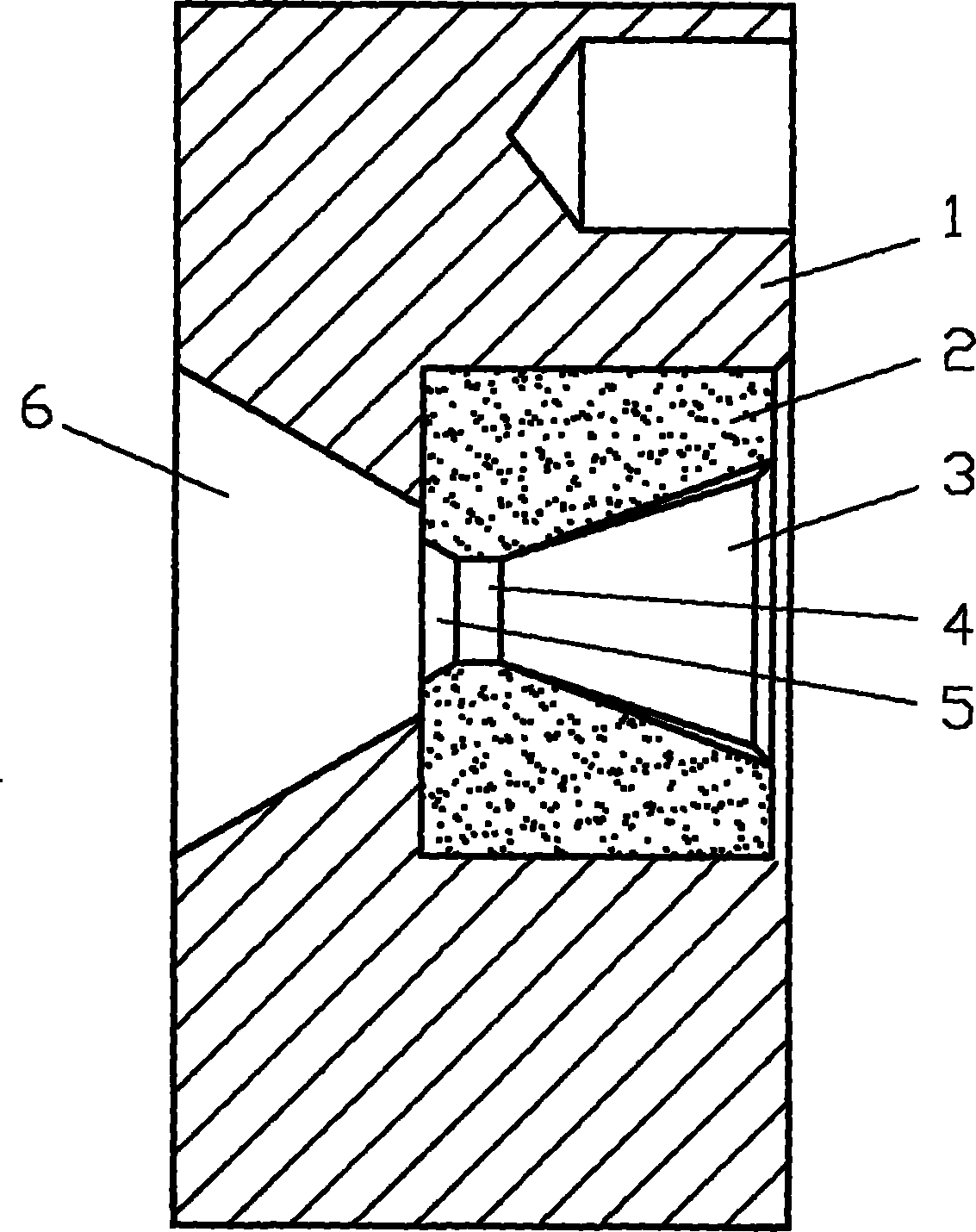

[0010] As shown in the accompanying drawings, the present invention includes a die set 1 and a die 2, the die set 1 has a die groove and a conical outlet 6 communicating with the die groove, and the die groove is interference fit with the die 2. The drawing die 2 has a drawing die hole, and the drawing die hole is a transition section 3, a sizing section 4 and a talcum powder export section 5 successively from the entrance to the exit. The transition section 3 is a trumpet-shaped arc surface, which can prevent the surface of the drawing die 2 from being burned due to the friction of the high-wire disk element due to lack of talcum powder. The sizing section 4 is a twist-shaped arc. The outlet section 5 of the talcum powder is a trumpet-shaped arc surface, and the outlet section 5 of the talcum powder is the discharge port 6 of the die sleeve 1 . The material of the die cover 1 is Q235-A. The material of the drawing die 2 is YG8 cemented carbide, which is formed by sintering...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com