Die repairing device

A mold and component technology, applied in the field of mold maintenance devices, can solve problems such as poor safety, increased safety risks, and low efficiency, and achieve the effects of improving work efficiency, high degree of automation, and reducing safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

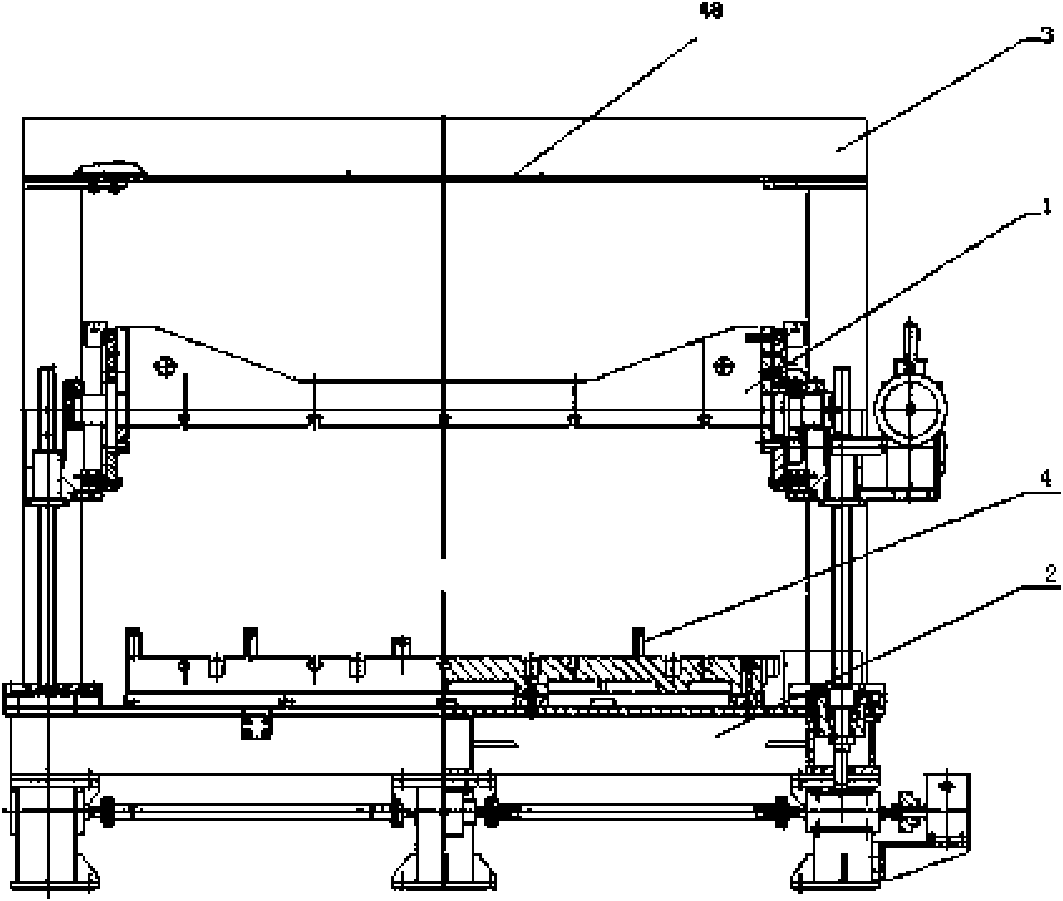

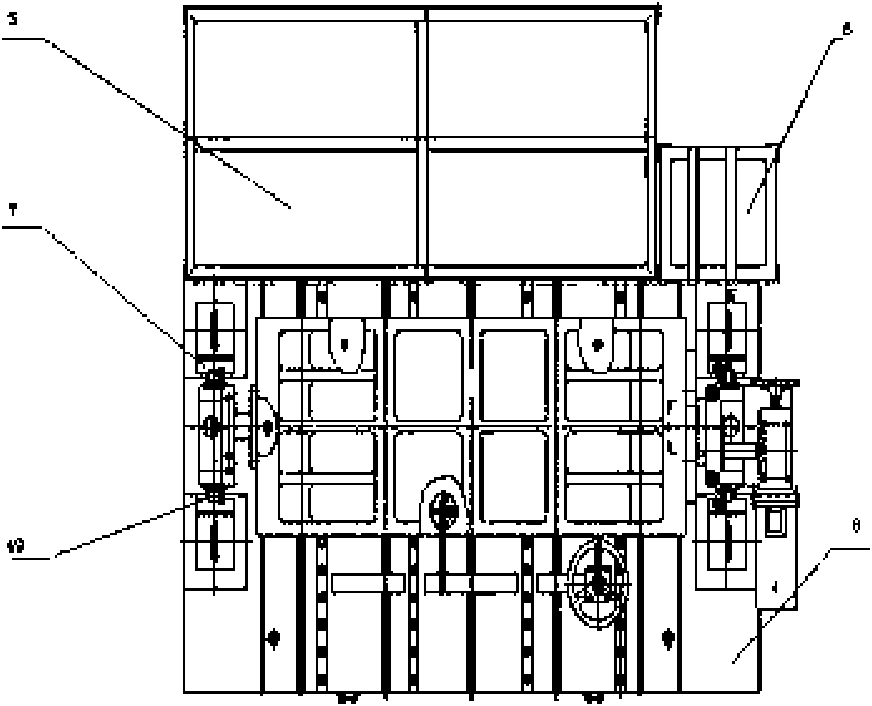

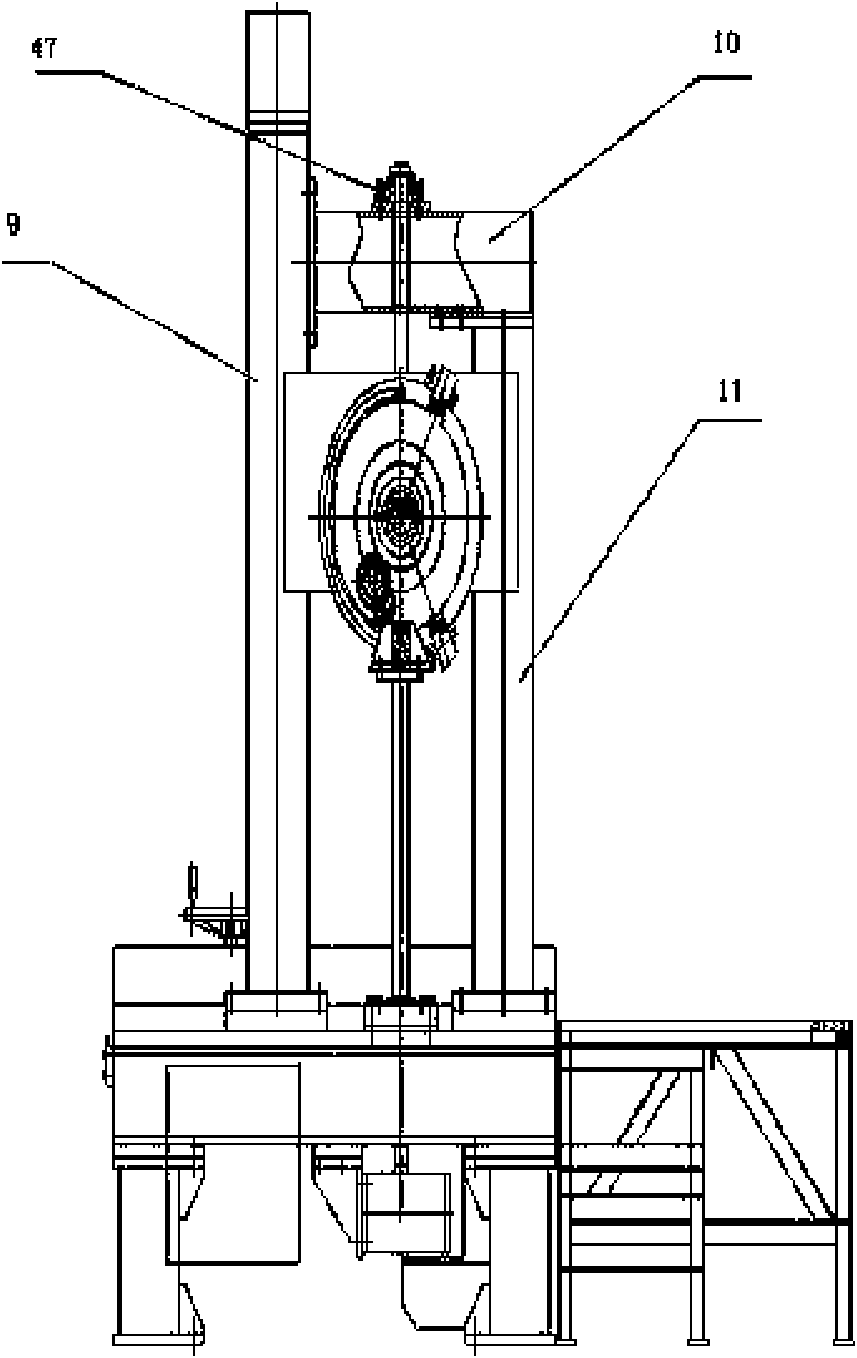

[0023] like figure 1 , figure 2 and image 3 As shown, the present invention includes a lower workbench assembly 1, a rotary workbench 2, a limit pin 4, a long column 9, a short column 11, a longitudinal beam 10, a linear guide rail 49, a beam 3, an operation platform 5, an operation ladder 6, a spherical Rolling bearing 47, track positioning plate 7, lighting equipment 48, control system 8; Figure 4 , Figure 5 and Image 6 As shown, the lower workbench assembly 1 is composed of a workbench 16, a main bracket assembly 17, a screw assembly 14, a support assembly I20, a support assembly II22, a support assembly III23, an eccentric wheel assembly 13, a handwheel assembly 12, and a hydraulic lifting guide rail 15. Electromagnetic clutch 18, reducer 19, shaft coupling 21, reducer 24, reducer 45, overload protector 25 and motor 26. The surface of the workbench 16 is designed with a T-shaped groove for fixing the mold, a U-shaped groove for installing the hydraulic lifting gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com