High flow-rate medium pressure resin bed

A high flow rate, resin bed technology, applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as increased manufacturing costs, easy to pull out welded joints, and reduced space. Achieve the effect of reducing manufacturing cost and operating cost, reducing material cost and processing cost, and avoiding irreparable damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

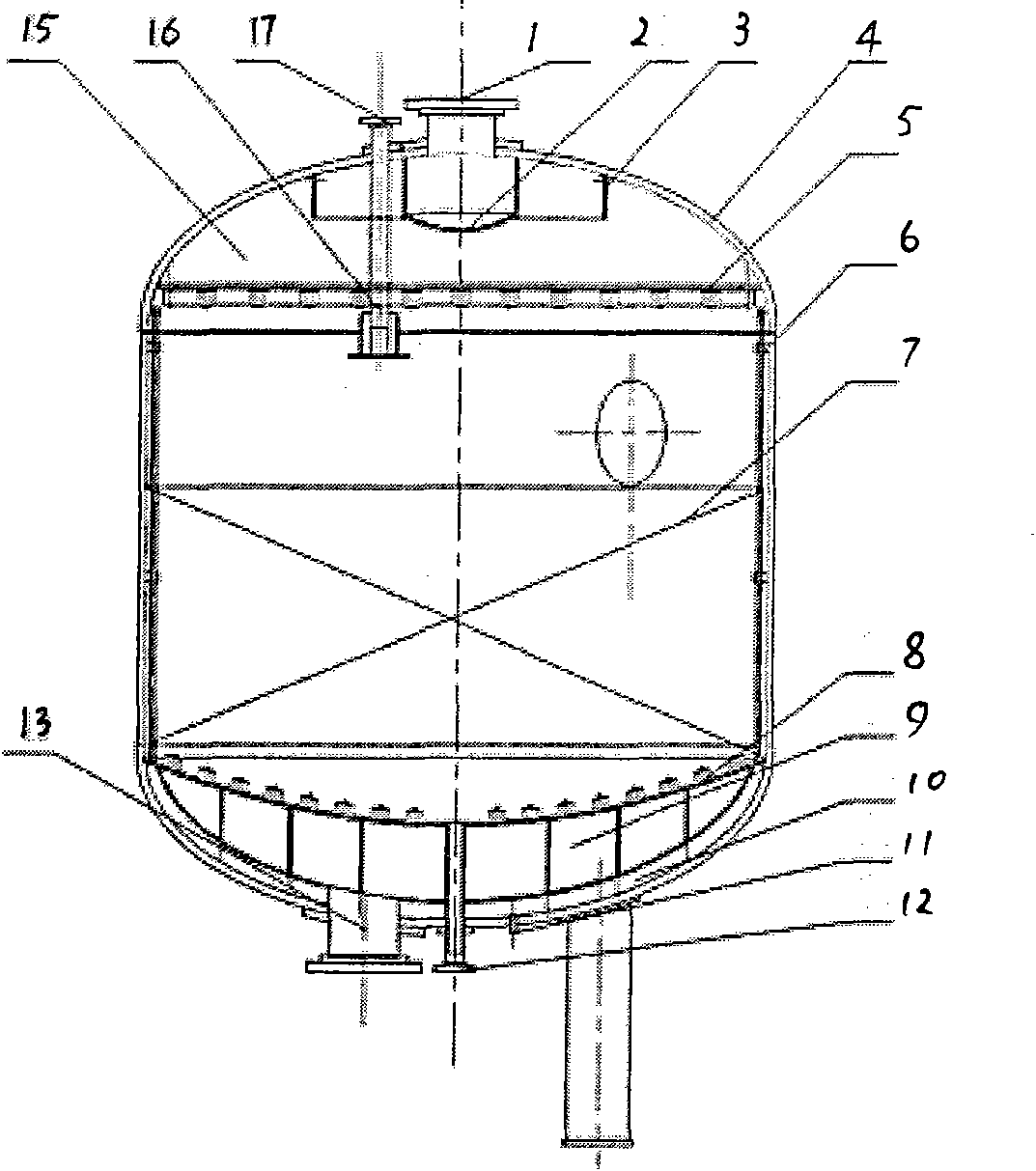

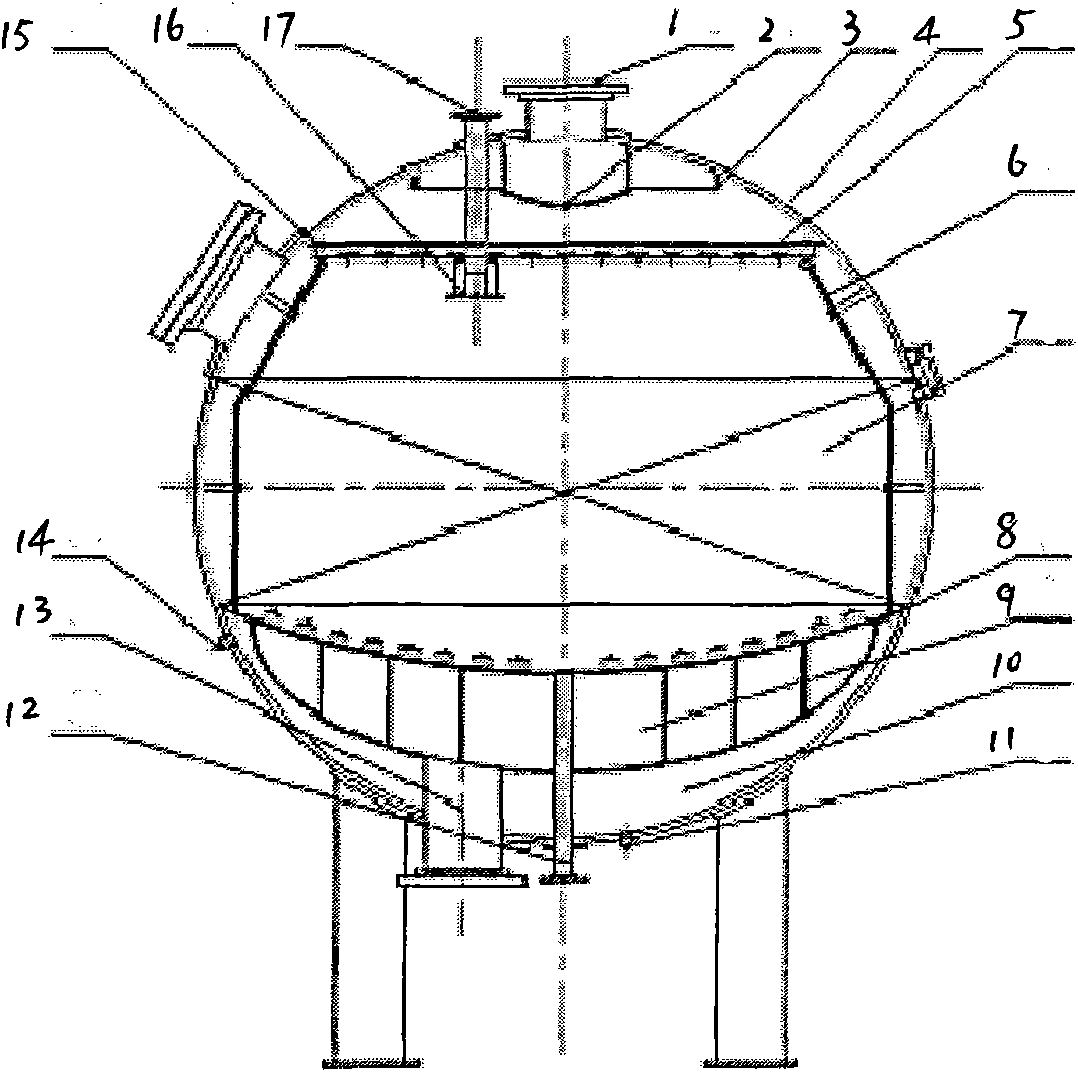

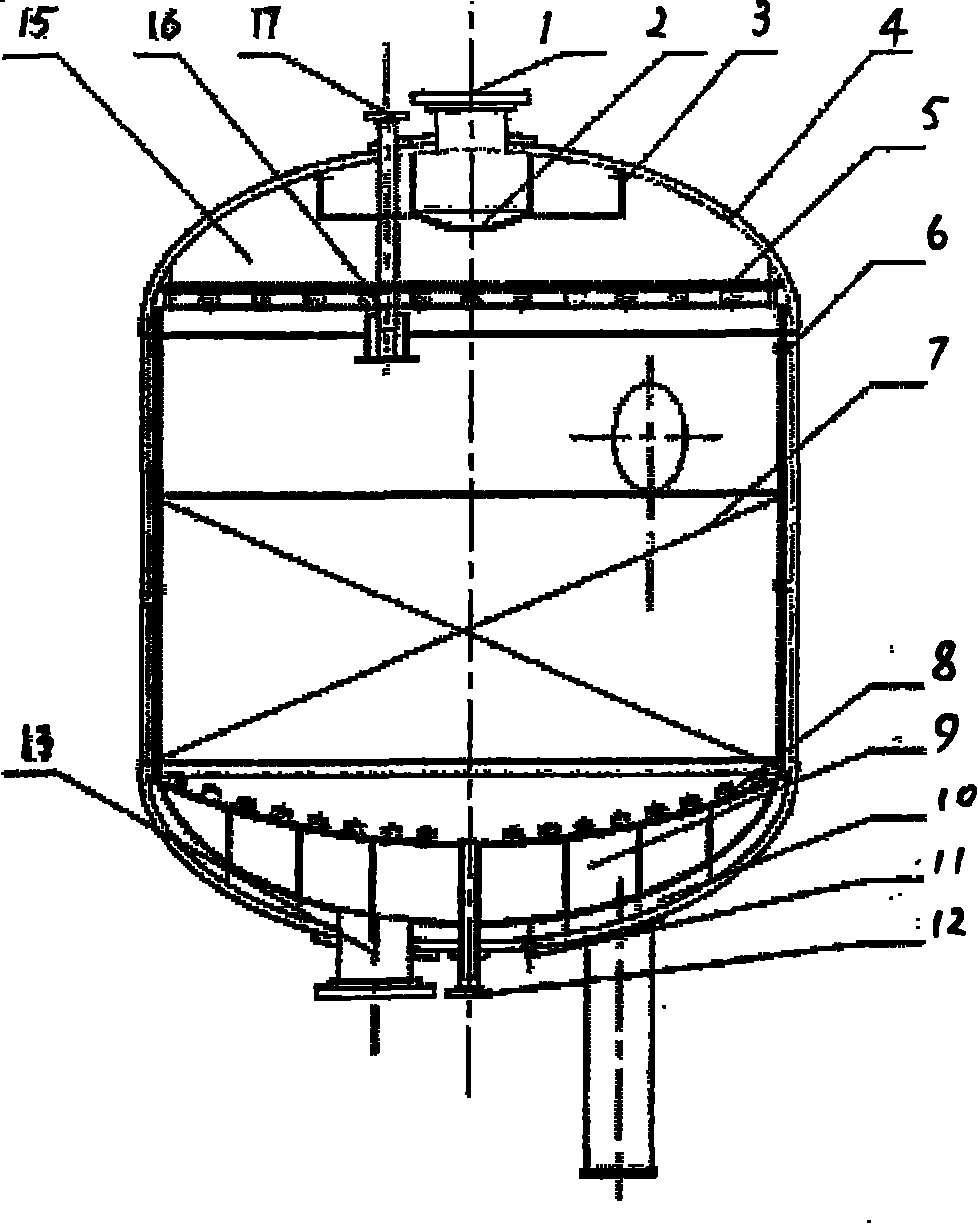

[0018] The device of the present invention will be further described below in conjunction with the accompanying drawings.

[0019] A medium-pressure resin bed with a high flow rate, with a cylinder flow rate of 80-120m / h, a design pressure of PN1.6 to 5.0MPa, and a design temperature of 30°C to 85°C.

[0020] figure 1 Shown is a high flow rate medium pressure resin bed, its structure mainly includes water inlet 1, water baffle plate 2, splash guard 3, cylinder body 4, water inlet device 5, pressure balance pipe 6, resin layer 7, water outlet device 8. Water outlet area 9, pressure balance area 10, balance area drain port 11, resin outlet port 12, water outlet port 13, balance area exhaust port 14, water inlet device support ring 15, resin inlet baffle plate 16, resin inlet port 17 .

[0021] The barrel 4 of the high-flow medium-pressure resin bed can be spherical or cylindrical. For containers with the same wall thickness, the pressure resistance of the spherical container i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap