Method for designing non-overload vortex pump impeller with edge folding blades

A design method and technology of vortex pumps, which are applied to components, pumps, and pump components of pumping devices for elastic fluids, can solve problems such as increasing power reserve coefficients, energy waste, and increased investment, and achieve reduced circulation Effects of flow loss, investment reduction, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

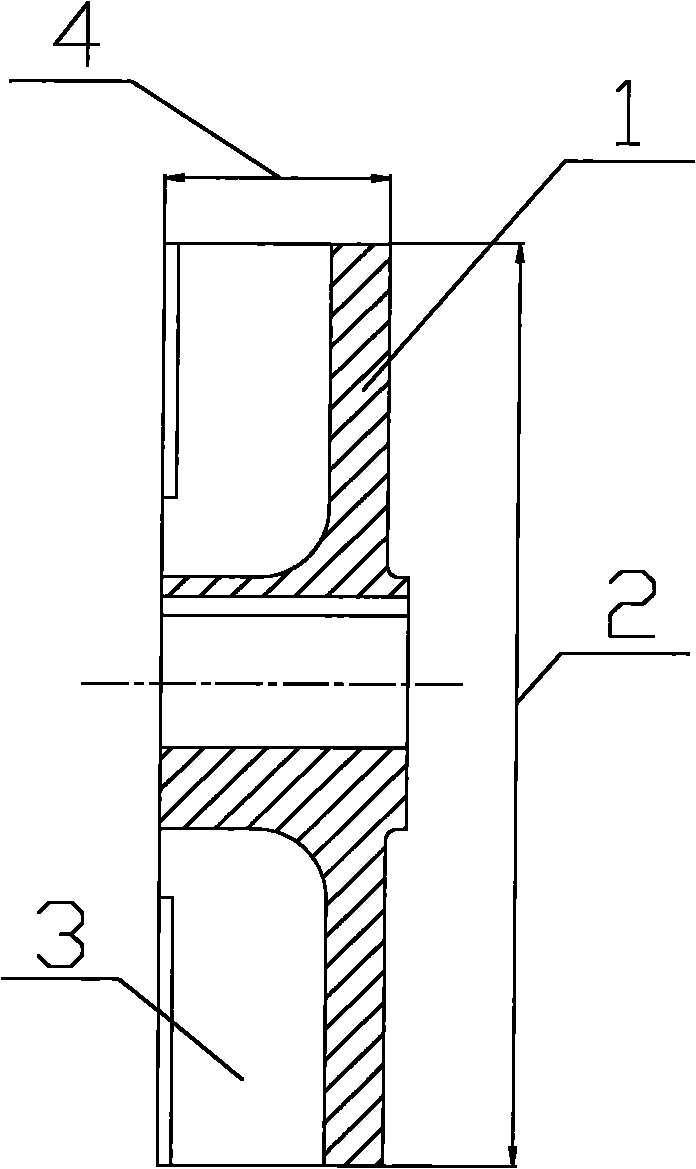

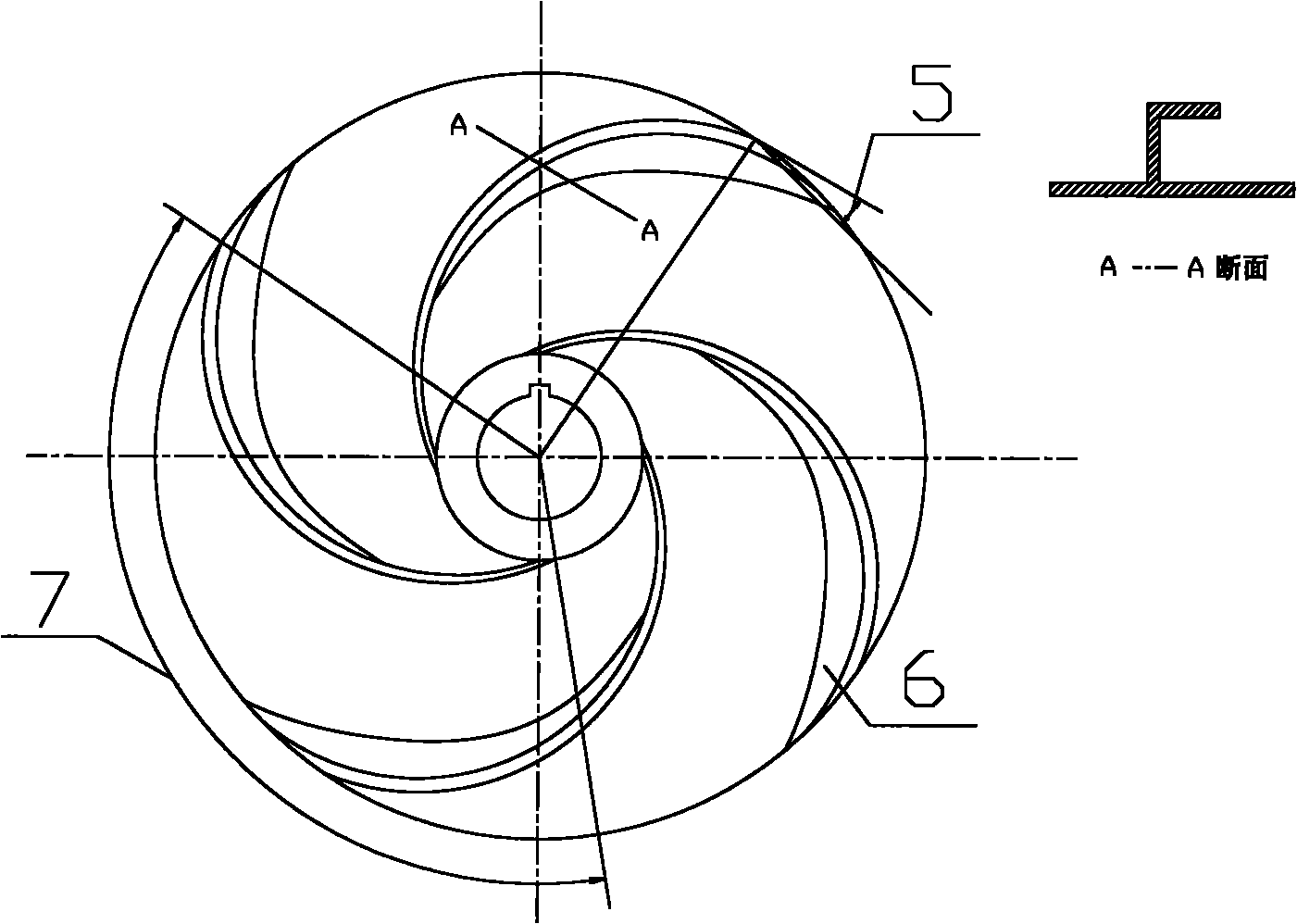

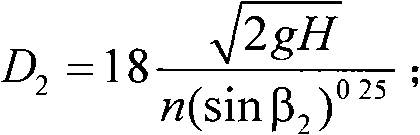

[0028] figure 1 and figure 2 Together determine the impeller shape for this embodiment. Like most centrifugal pump impellers, it has an impeller back cover (1) and is an open impeller. The direction of the flanging (6) is opposite to the direction of rotation of the impeller. When the vortex pump is running, the folded edge (6) can limit the circulation flow from radial direction to axial direction, reduce the loss of circulation flow, and improve the lift and efficiency. The present invention determines the outlet width b of the impeller blades through the following relational expressions 2 , The diameter of the outer circle of the impeller blade D 2 , The outlet angle β of the impeller blade 2 , impeller blade wrap angle and the flange width B, so that the performance of the vortex pump in this embodiment meets the requirements of the full head.

[0029] D 2 = 18 2 gH ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap