Hot-air air conditioner using biomass fuel

A biomass fuel and air conditioner technology, which is used in air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of insufficient fuel combustion, insufficient oxygen supply to combustion materials, and low heat conversion efficiency, and achieve combustion Sufficient, high heat conversion efficiency, effect of dispersing wind speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

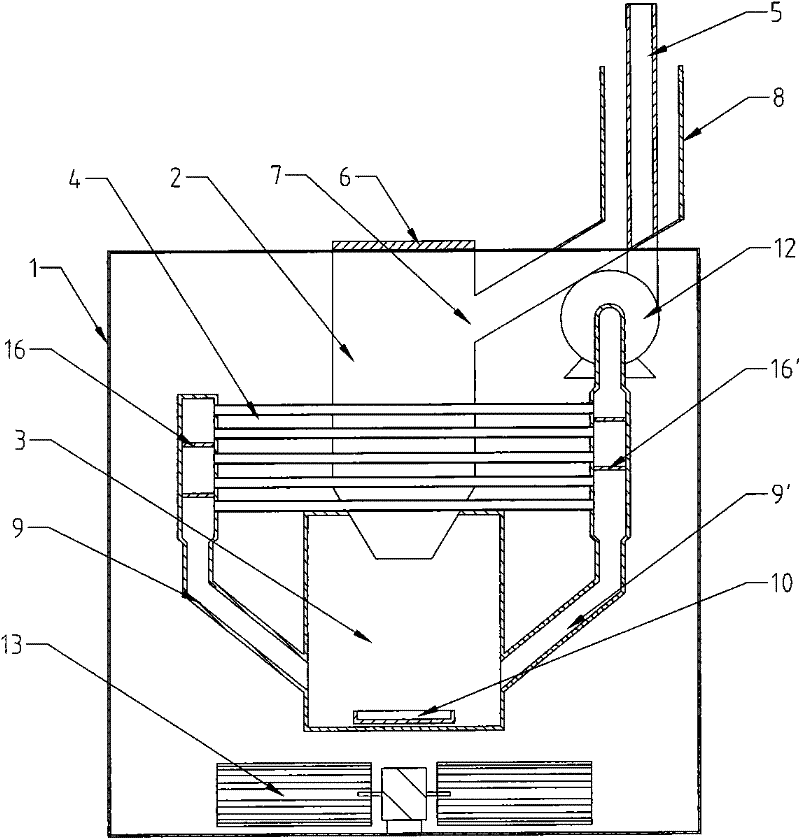

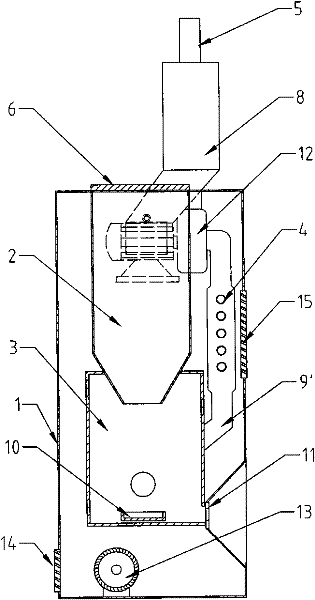

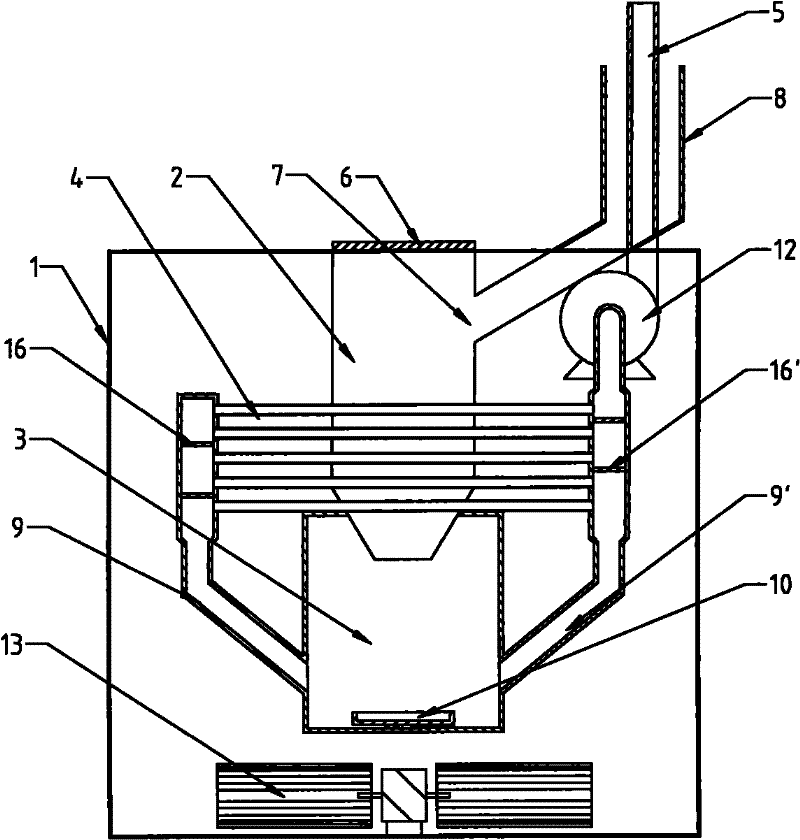

[0010] Reference attached figure 1 And attached figure 2 , a hot-air air conditioner utilizing biomass fuel, comprising a casing 1, a biomass energy conversion device, and a hot-air exchange device; the biomass energy conversion device and the hot-air exchange device are jointly installed in the casing 1; the biomass energy conversion device It is mainly composed of a biomass storage bin 2, a combustion chamber 3, a heat exchanger 4 and a smoke exhaust pipe 5; the top of the biomass storage bin 2 has a feeding port and a sealing cover 6, and the air inlet 7 on the upper side is connected to Intake pipe 8, the bottom of biomass storage bin 2 is a funnel-shaped opening, connected with the top of combustion chamber 3; the side wall of combustion chamber 3 has a conduit 9 and a conduit 9' leading to heat exchanger 4; the bottom of combustion chamber 3 has There is a glass door 11 leading to the cabinet 1 on the bottom side, and a secondary air supply adjustment port is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com