Efficient long-service-life single-runner secondary combustion oxygen lance and using method

A secondary combustion, single-channel technology, applied in the direction of improving process efficiency, manufacturing converters, etc., can solve the problems of reducing the concentration of converter gas, low efficiency of concentrated combustion, affecting the gas volume of converter gas recovery, etc., to improve the secondary Combustion rate, increasing converter scrap ratio, improving the effect of metallurgical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

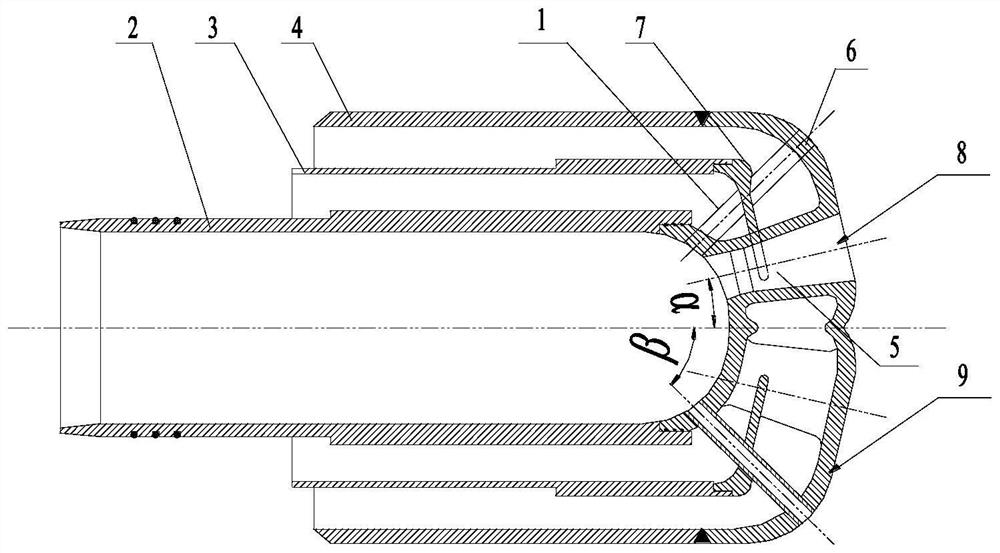

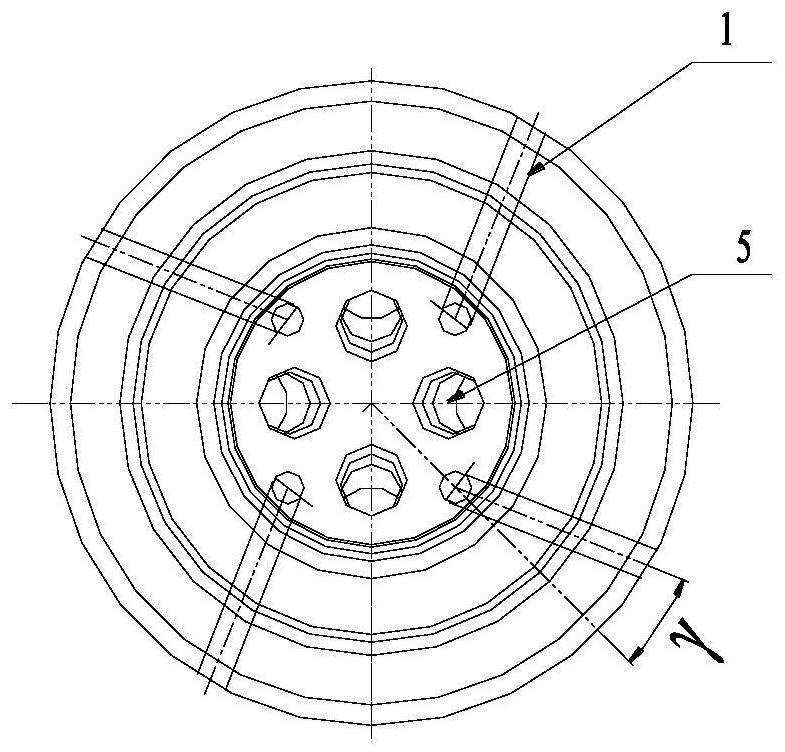

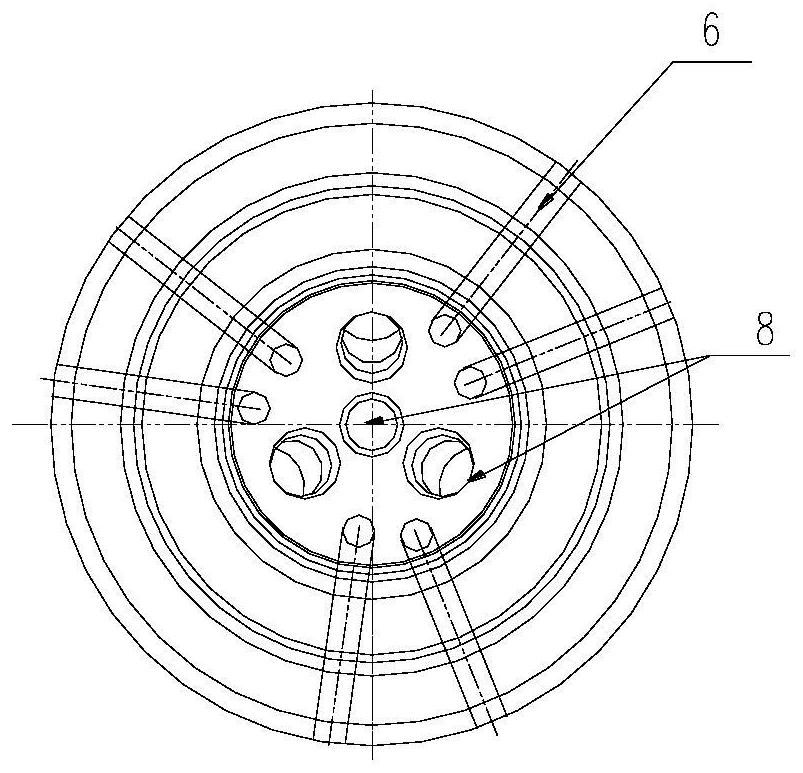

[0026] Example 1: as figure 1 , 2 The shown 150-ton converter high-efficiency and long-life single-flow secondary combustion oxygen lance includes a gun body and a gun head; the gun body includes an outer tube 4, a middle tube 3 and a center tube 2, and the ring between the middle tube 3 and the center tube 2. The seam is the water inlet channel, the annular seam between the middle tube 3 and the outer tube 4 is the water outlet channel, and the central tube 2 is the oxygen injection channel; A circle of main injection holes 8 and a circle of auxiliary injection holes 6 are evenly arranged on the end 9 of the gun head along the circumferential direction, and the auxiliary injection holes 6 are located on the outer ring, the main injection holes 8 are located in the inner circle, and the injection holes are The number of main holes is the same as the number of auxiliary blowing holes, and they are arranged alternately and evenly. A main hole flow channel 5 extends inward alon...

Embodiment 2

[0029] Example 2: as figure 1 , 2 The 300-ton converter shown is a high-efficiency long-life single-channel secondary combustion oxygen lance. The structure of the oxygen lance is the same as that of Example 1, and the use method of the oxygen lance is slightly different, specifically: using the above-mentioned high-efficiency and long-life single-flow secondary combustion oxygen lance to carry out converter blowing in a 300-ton converter according to the constant pressure variable lance position operation process With the slag splashing protection furnace, the oxygen pressure is controlled at 0.9-1.3Mpa, the blowing gun position is 40-80mm lower than the traditional gun position (1.9-2.4m), the nitrogen pressure during slag splashing is controlled at 0.9-1.3Mpa, and the slag splashing gun is controlled at 0.9-1.3Mpa. The position is 0 ~ 80mm lower than the traditional oxygen lance position (0 ~ 2.0m); the oxygen flow rate Q = W · T, where Q is the oxygen consumption of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com