Fire coal gasification ring

A technology for burning coal and air intake pipes, which is applied to heating fuels, gaseous heating fuels, household stoves/stoves, etc., can solve the problems of insufficient oxygen combination, low heat energy utilization efficiency, poor air circulation effect, etc., to improve resources Effective utilization efficiency, improved thermal energy utilization efficiency, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

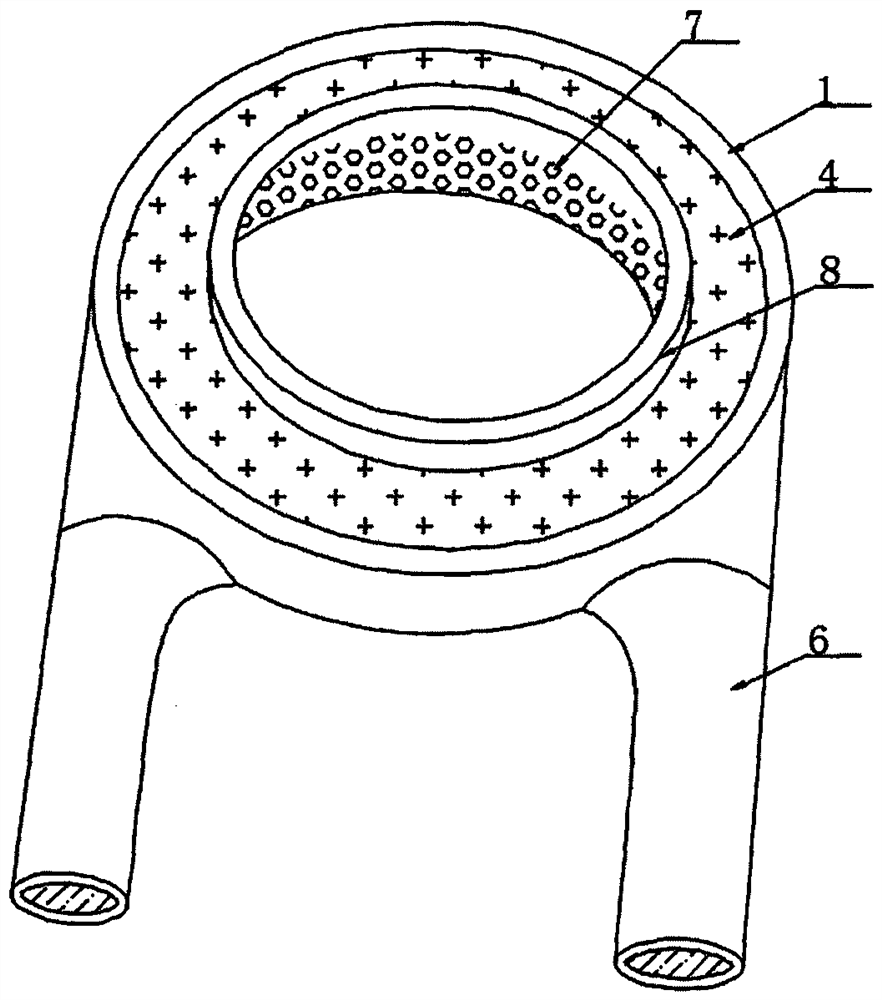

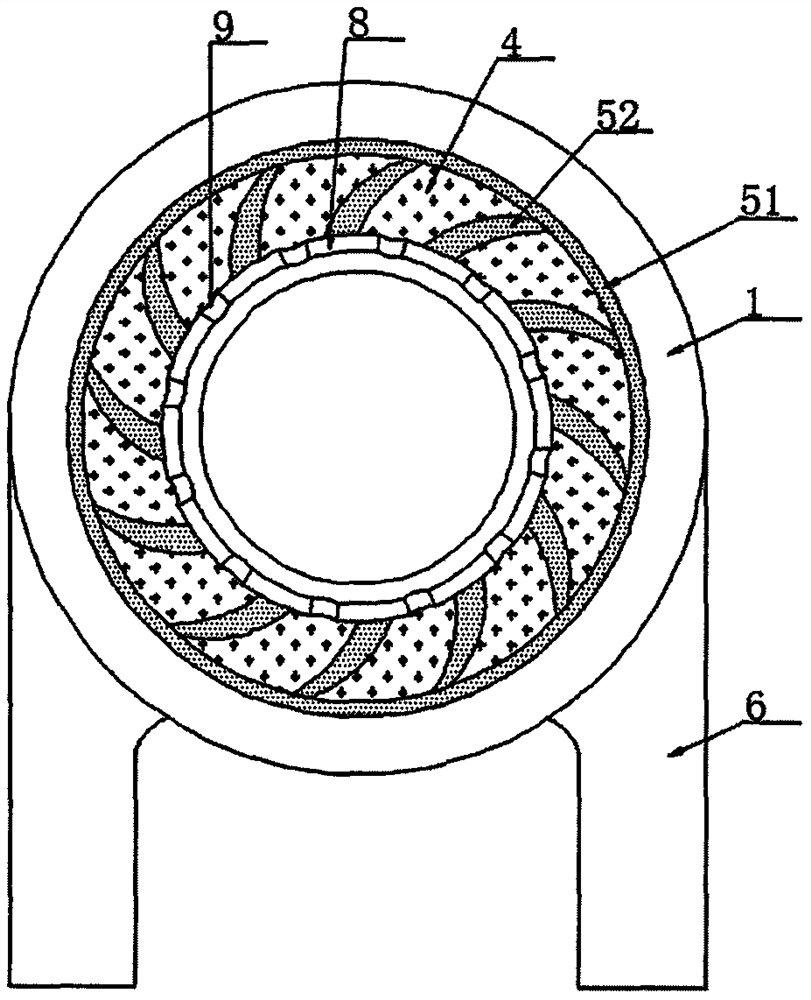

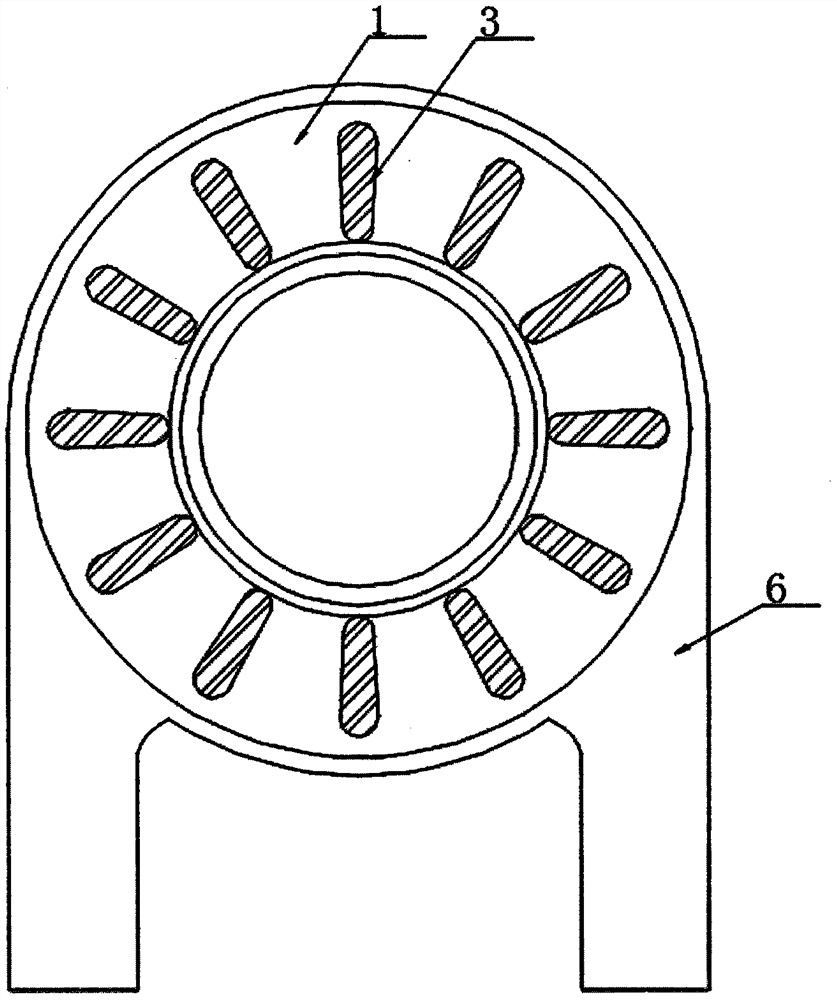

[0031] according to Figure 1-7 The coal-fired gasification ring shown includes a sealing steel ring 1, the interior of the sealing steel ring 1 is set as a cavity 2, the bottom of the sealing steel ring 1 is provided with a support plate 3, and the top of the sealing steel ring 1 is A placement groove 4 is provided, and a bearing frame 5 is movably connected in the placement groove 4. An air intake pipe 6 is provided on one side of the sealing steel ring 1, and an evenly distributed exhaust hole 7 is provided on the inner wall of the sealing steel ring 1. , the inner top of the sealing steel ring 1 is provided with a support flange 8, and the upper surface of the support flange 8 is provided with a channel 9;

[0032] The bottom of the support plate 3 is set as an inclined surface, and the surface of the support plate 3 is provided with anti-skid embossed lines;

[0033] An anti-slip layer is provided inside the placement groove 4, and the anti-slip layer is composed of seve...

Embodiment 2

[0046] according to Figure 1-7 The coal-fired gasification ring shown includes a sealing steel ring 1, the interior of the sealing steel ring 1 is set as a cavity 2, the bottom of the sealing steel ring 1 is provided with a support plate 3, and the top of the sealing steel ring 1 is A placement groove 4 is provided, and a bearing frame 5 is movably connected in the placement groove 4. An air intake pipe 6 is provided on one side of the sealing steel ring 1, and an evenly distributed exhaust hole 7 is provided on the inner wall of the sealing steel ring 1. , the inner top of the sealing steel ring 1 is provided with a support flange 8, and the upper surface of the support flange 8 is provided with a channel 9;

[0047]The inside of the cavity 2 is provided with a support rib, and the support rib is made of cast iron material;

[0048] The sealing steel ring 1 can be designed into various models according to the size, size and specifications of the gas furnace, such as single-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com