Optimization design method of step-stress accelerated degradation test

An accelerated degradation test and step stress technology, which is applied in the direction of measuring devices, instruments, and measuring electronics, can solve the problem that the optimized design variables do not include the test stress level, etc., and achieve the effect of improving the test optimization rate and reducing the number of calculations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

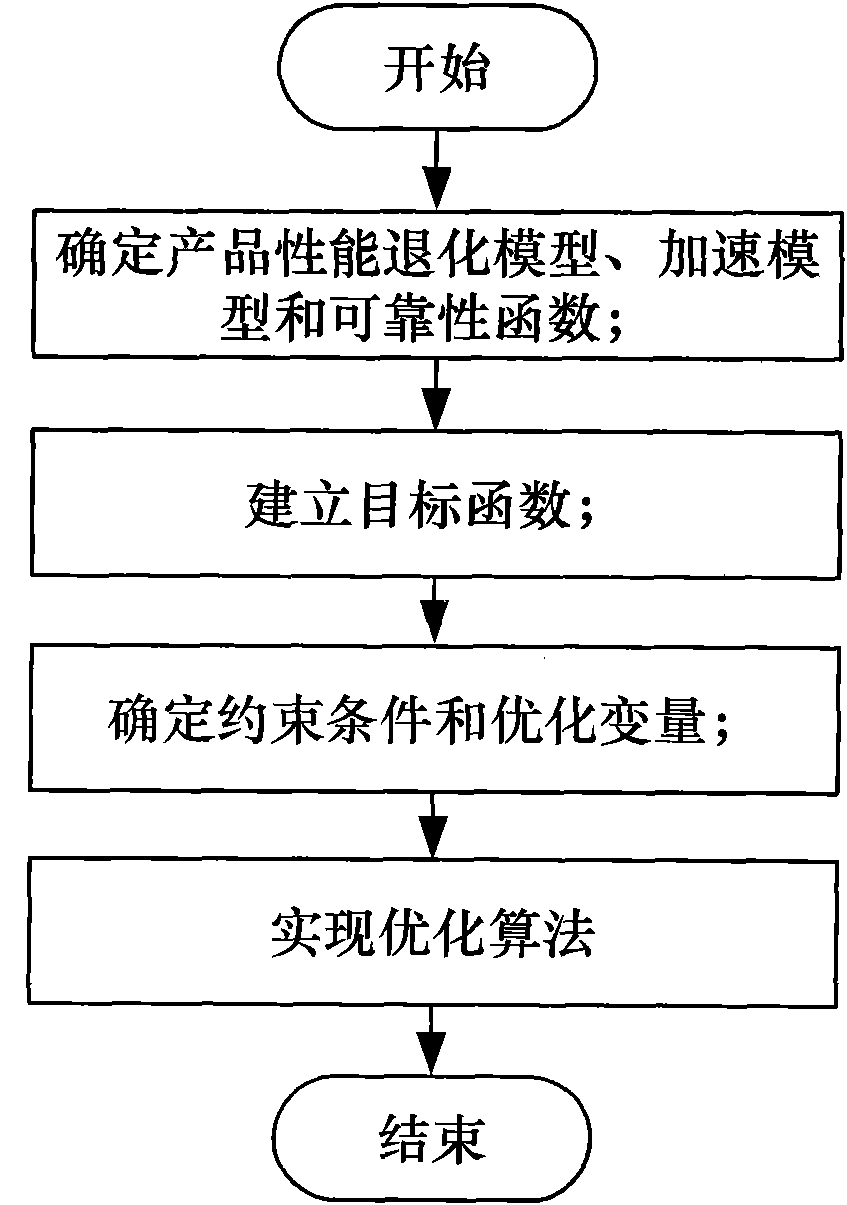

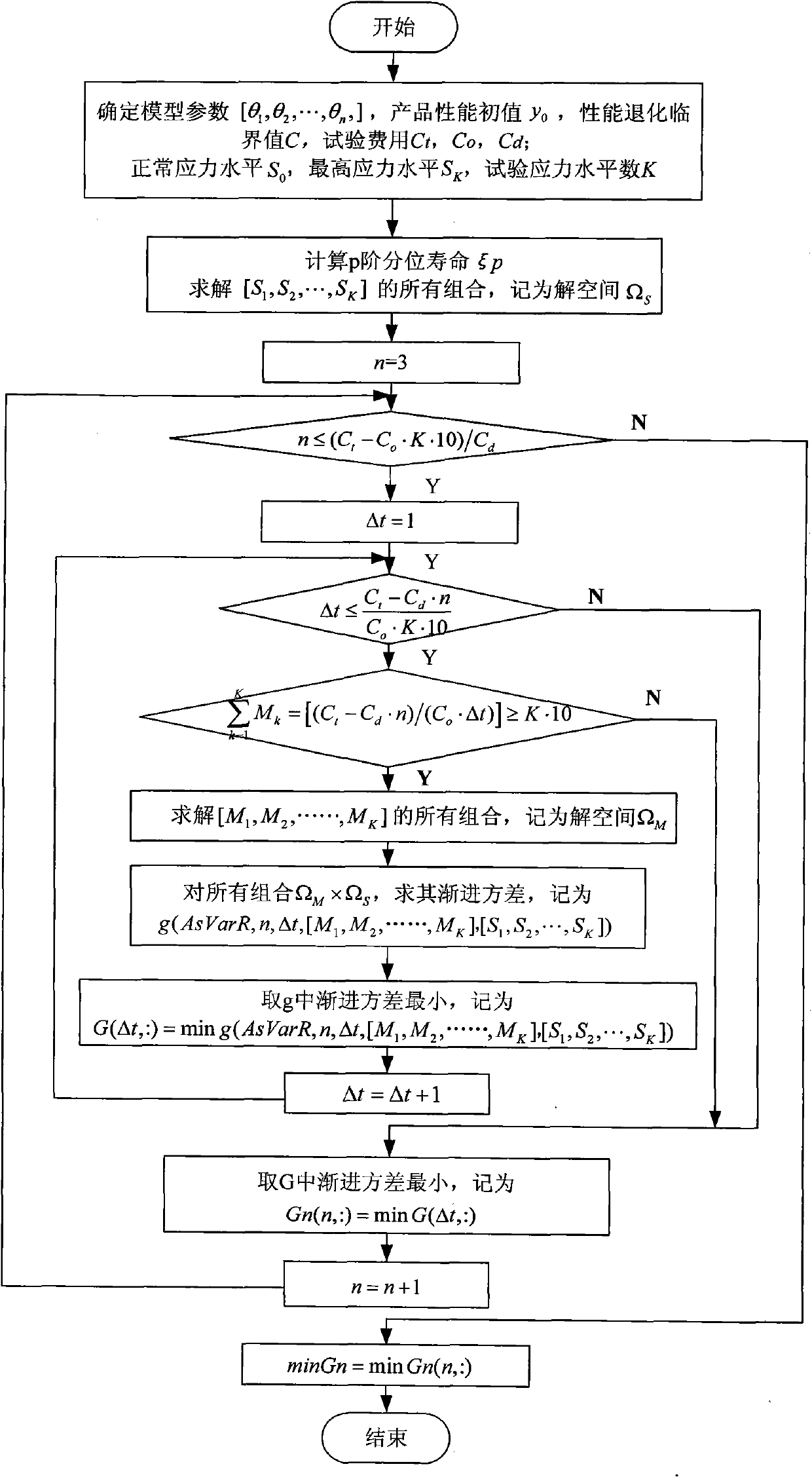

[0171] Step 1. Determine product performance degradation model, acceleration model and reliability function;

[0172] According to product characteristics, sensitive stress and performance parameter degradation trend, the drift Brownian motion model is used to describe the product performance degradation process, the test stress is temperature T, and the corresponding acceleration model is the Arrhenius model. Then determine the product performance degradation model as formula (1).

[0173] The reliability function of the product under normal stress is:

[0174] R ( t ) = Φ [ C - y 0 - ( A + B / T 0 ) · t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com