Inter-partition dual-vector model predictive control method for parallel PWM rectifier

A model predictive control and rectifier technology, which is applied in the direction of conversion of AC power input to DC power output, irreversible AC power input conversion into DC power output, and output power conversion device, etc., which can solve the problem of poor circulation suppression effect and processor Long calculation time, reducing the reliability and efficiency of the control system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

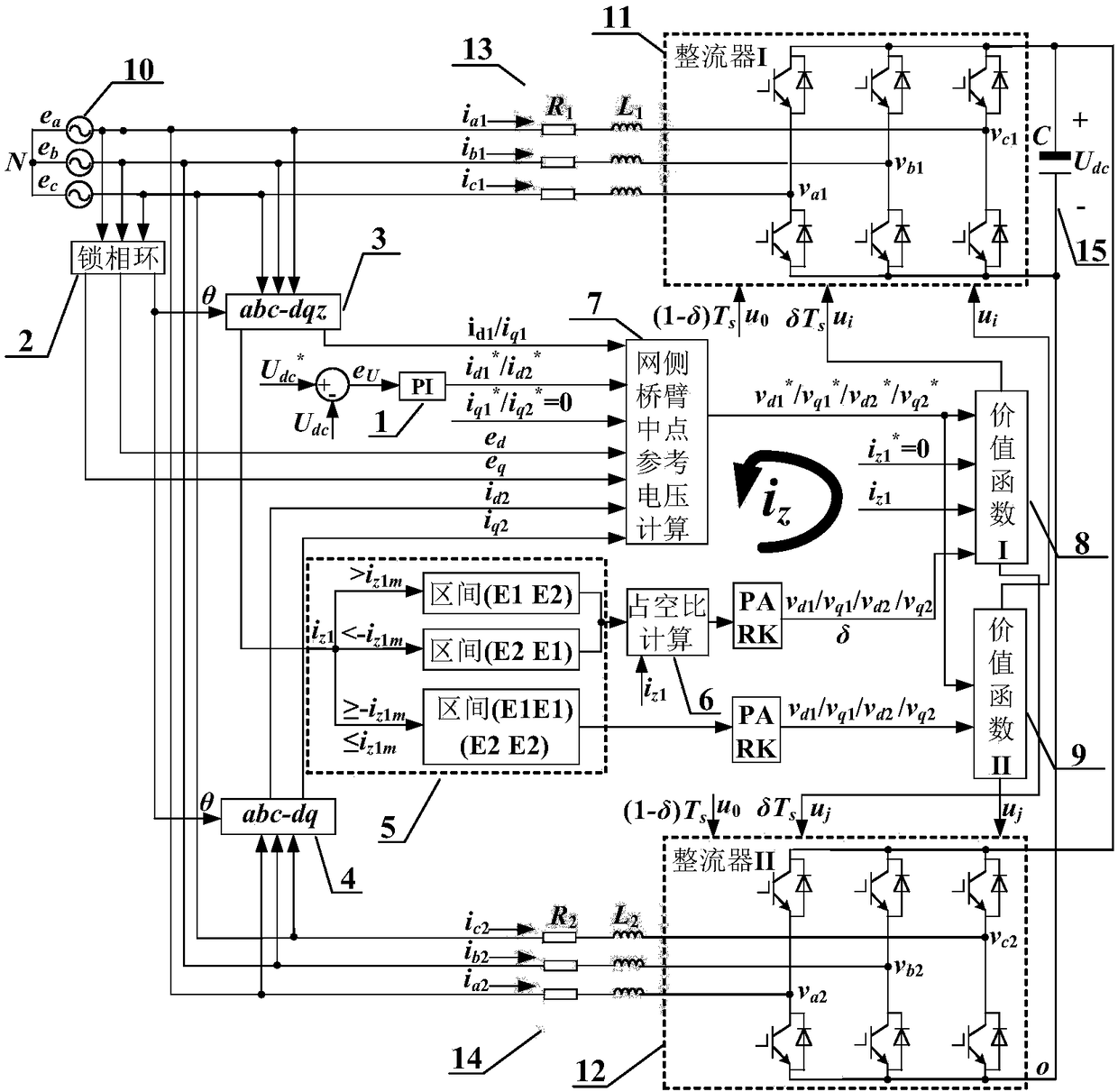

[0052] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0053] The schematic diagram of a parallel PWM rectifier segmental dual-vector model predictive control method is as follows: figure 1 shown, including the following steps:

[0054] Step 1: Real-time calculation of d-axis current reference value i on the grid side of the rectifier through the voltage PI controller d1 * / i d2 * . The specific method is:

[0055] The DC side reference voltage U dc * and the actual voltage U on the DC side dc The difference e U The input voltage PI controller obtains the d-axis current reference value i of the grid side of the rectifier according to the formula (1.1) d1 * / i d2 * :

[0056]

[0057] Among them, K P and K I are the proportional gain and integral gain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com