Foam spray gun

A spray gun and foam technology, which is applied in the field of spray guns that can generate foam, can solve the problems of limited foam generation, affecting the use effect, laborious and other problems, and achieve the effect of good hand feeling and full foam generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

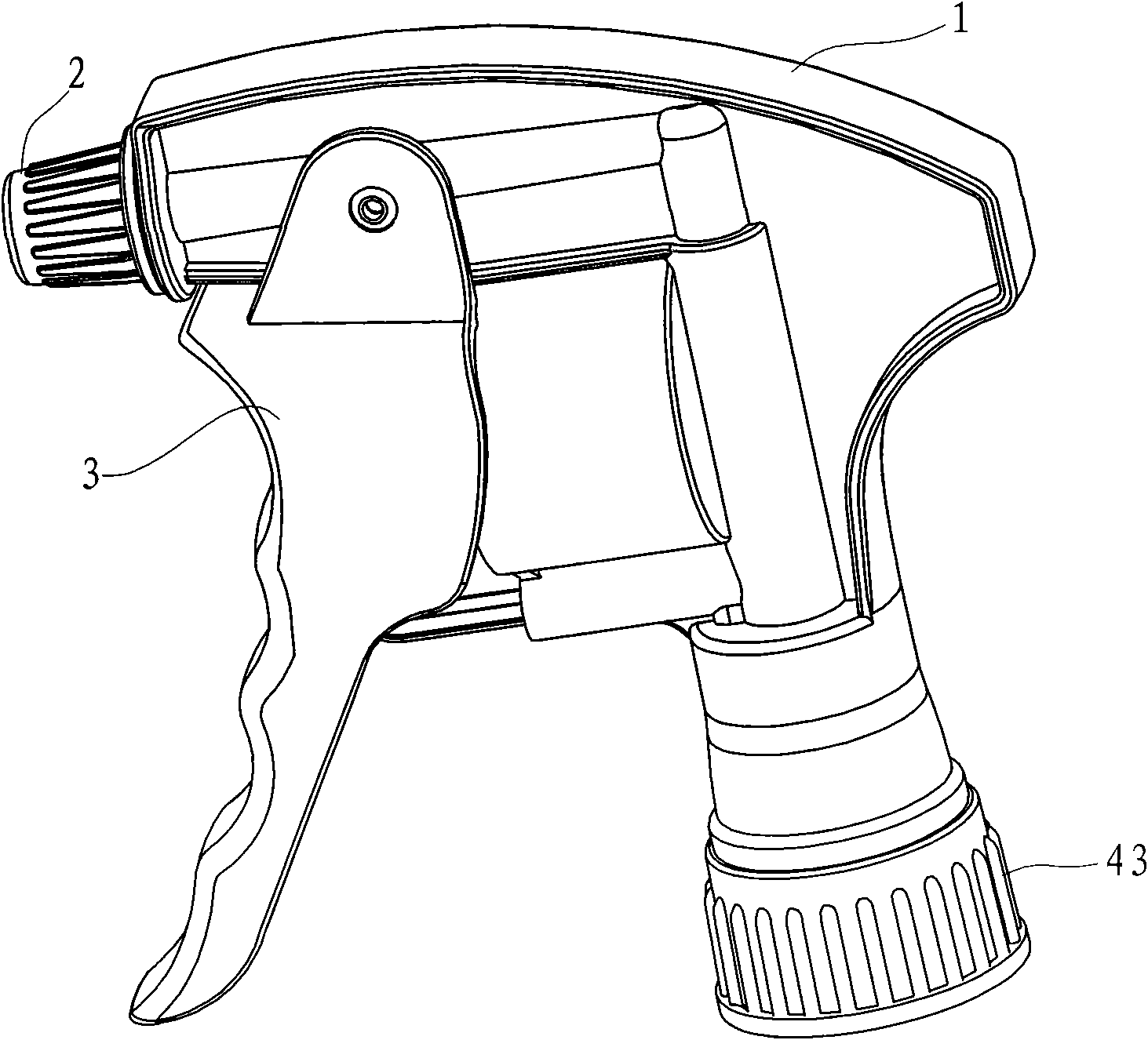

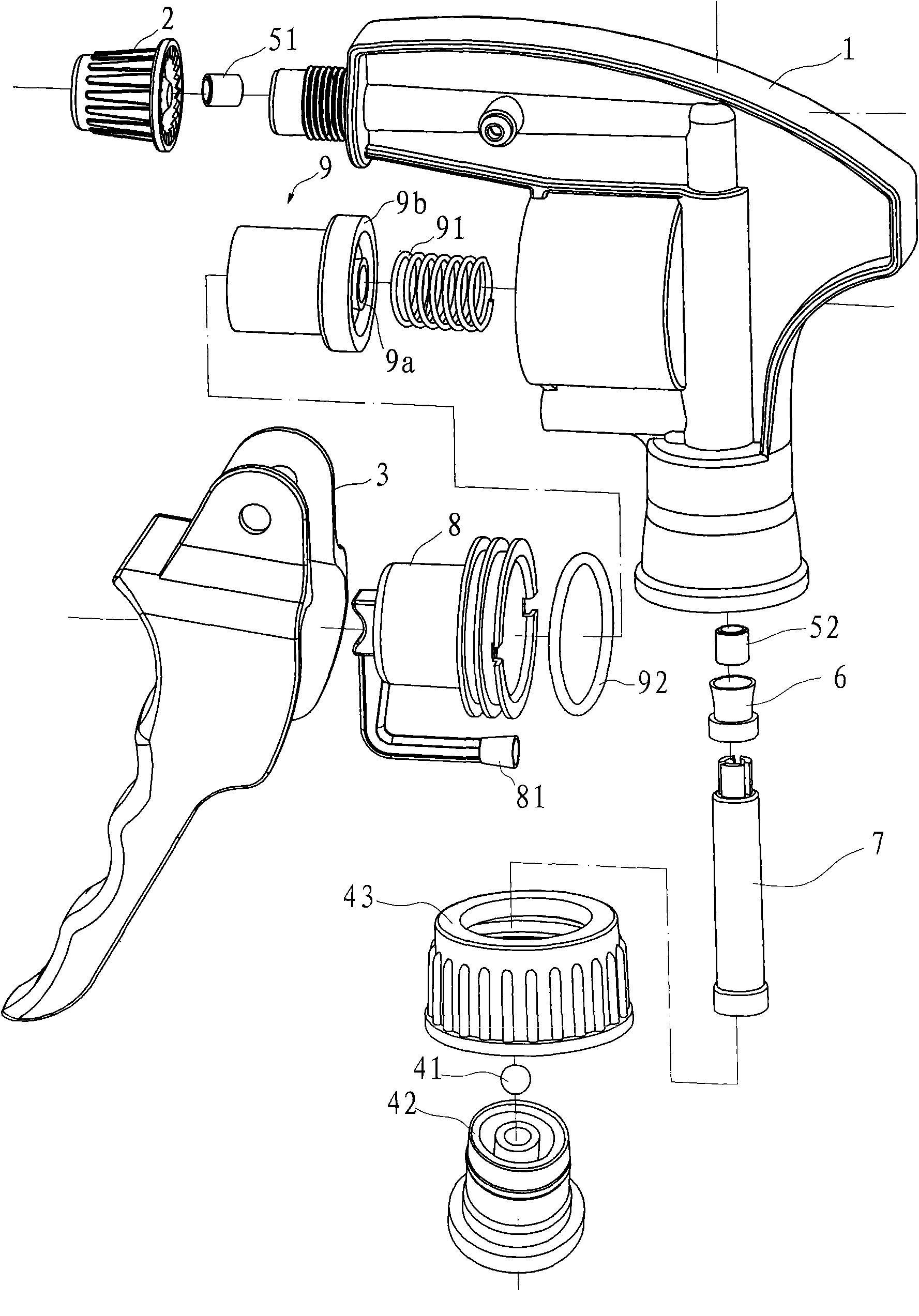

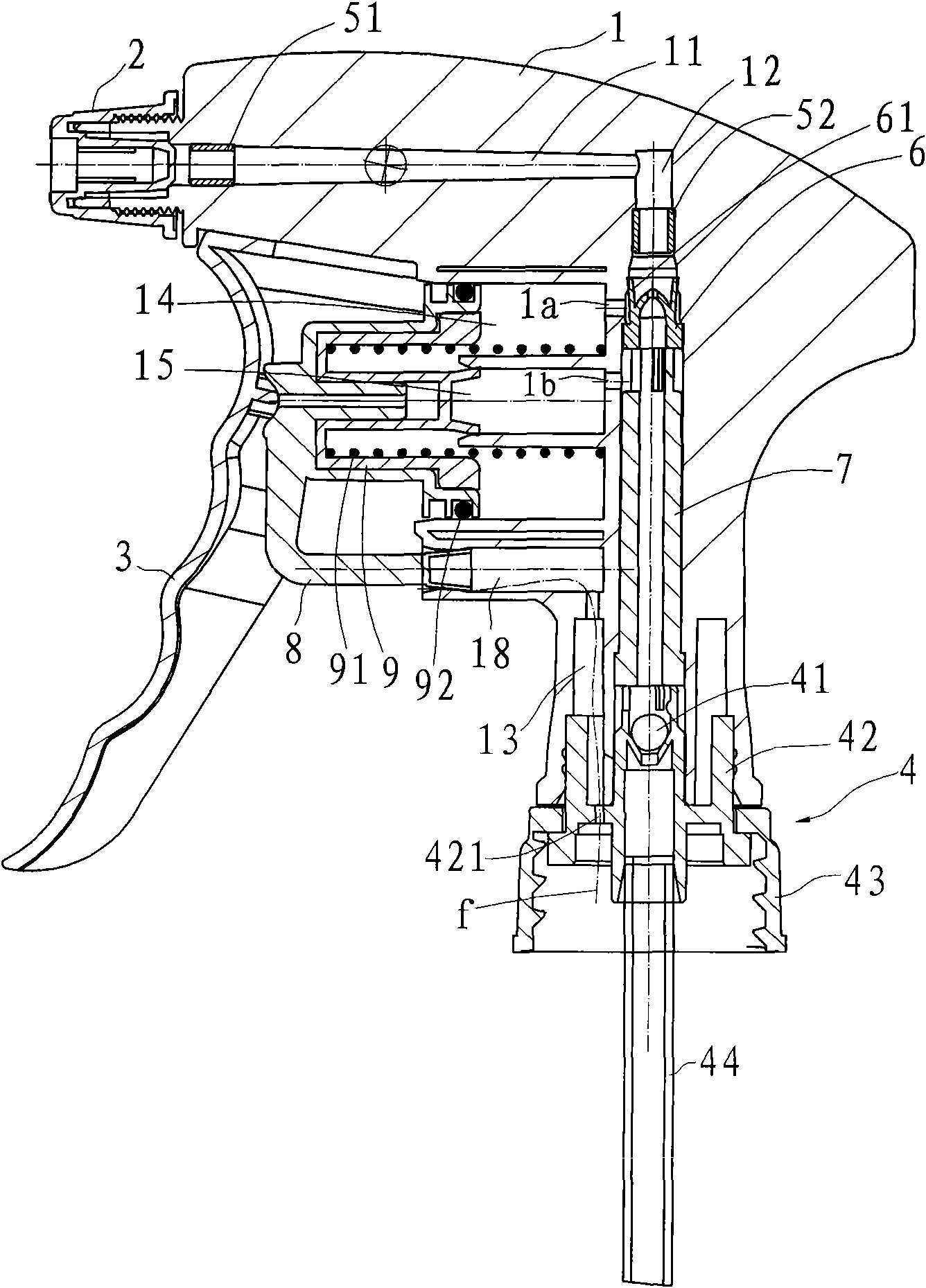

[0034] Example: such as figure 1 , figure 2 and image 3 As shown, the foam spray gun in this embodiment includes a gun body 1, a spray head 2, a wrench 3, a one-way liquid inlet mechanism 4, a piston rod 8, a piston 9, a reset member 91, a one-way valve 6, a first screen 51, The second screen 52 and the liner 7 .

[0035] The gun body 1 has a foam generating channel, and the foam generating channel includes a horizontal channel 11 and a vertical channel 12 . The nozzle 2 is arranged on the head of the gun body 1 and is connected to the injection port of the horizontal passage 11, and the wrench 3 is arranged on the gun body 1 in a rotatable manner.

[0036] The one-way liquid inlet mechanism 4 includes a pump body 42, balls 41 and a large cover 43. The pump body 42 is located at the liquid inlet port of the gun body 1, and the upper end has a V-shaped liquid outlet, and the lower end is connected with a water inlet pipe 44. Spheroid 41 is positioned on the V-shaped liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com