Apparatus and method for separating carrier liquid vapor from ink

A gas, pressurized gas technology, applied in the field of equipment and methods for separating carrier liquid vapor from ink, capable of solving problems such as re-dissolution, accumulation, deposition film contamination, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

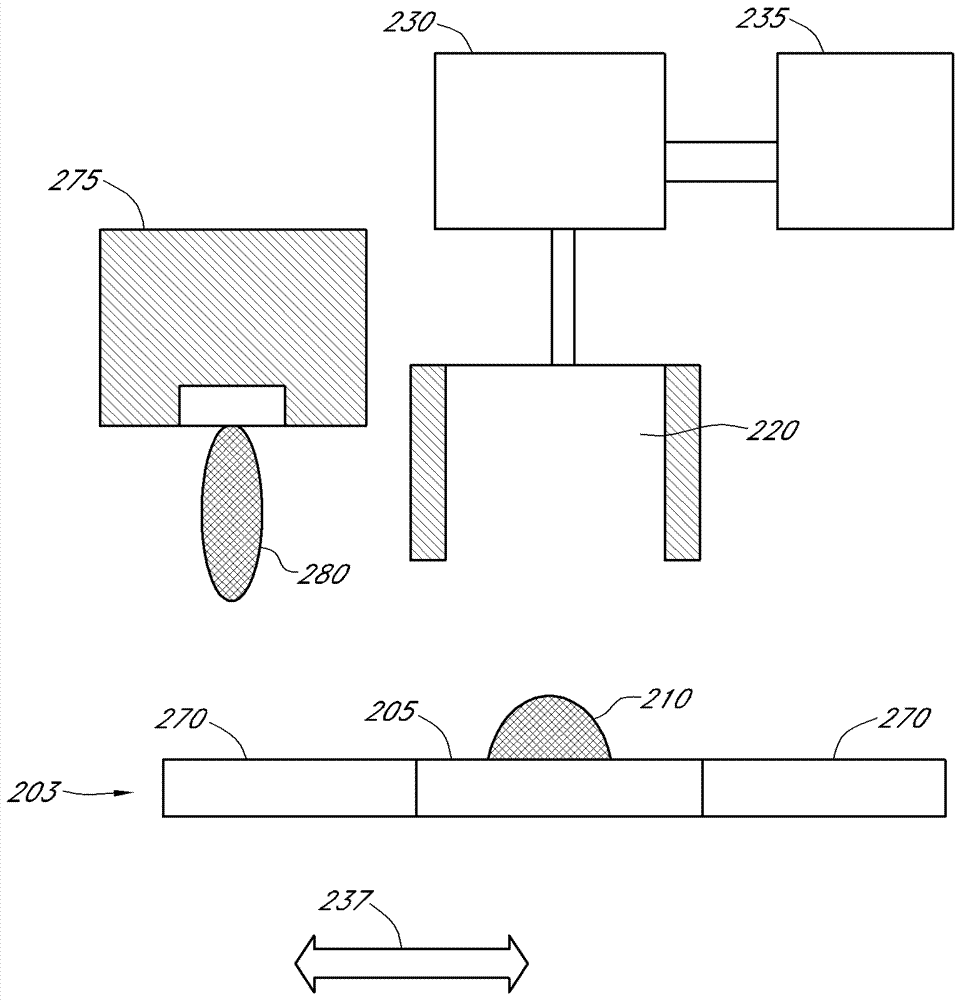

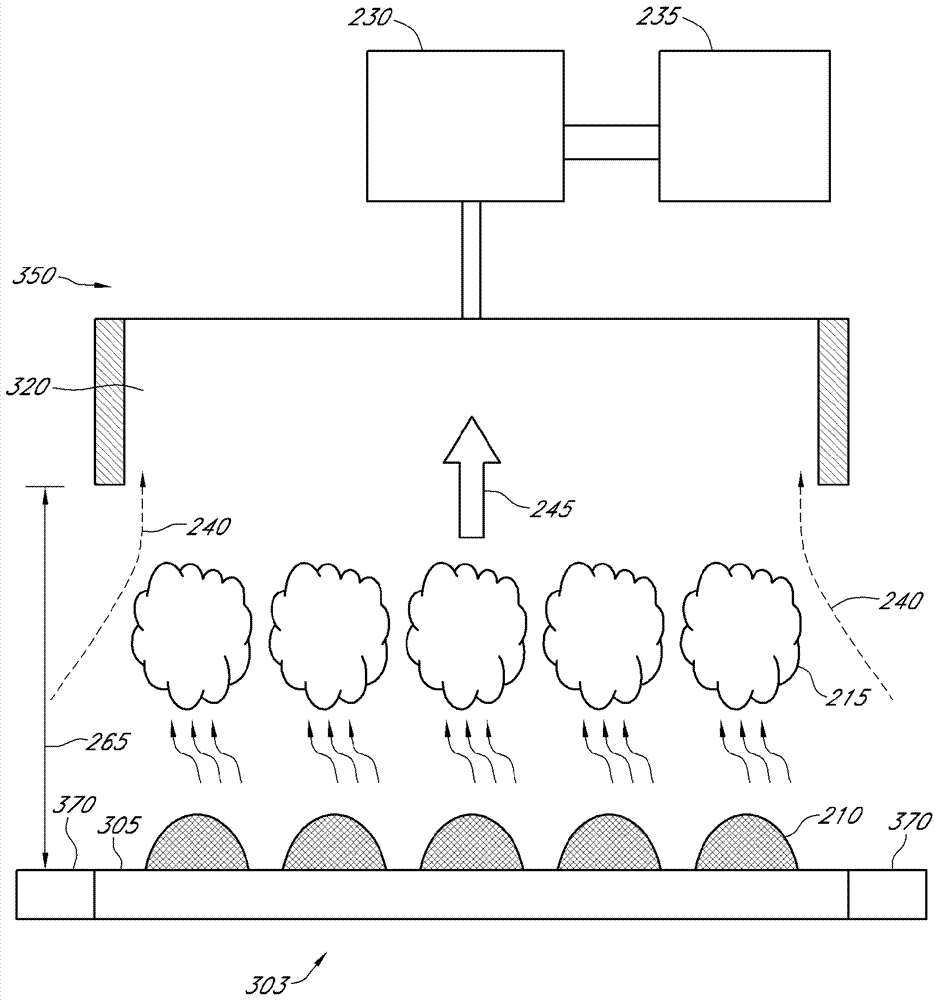

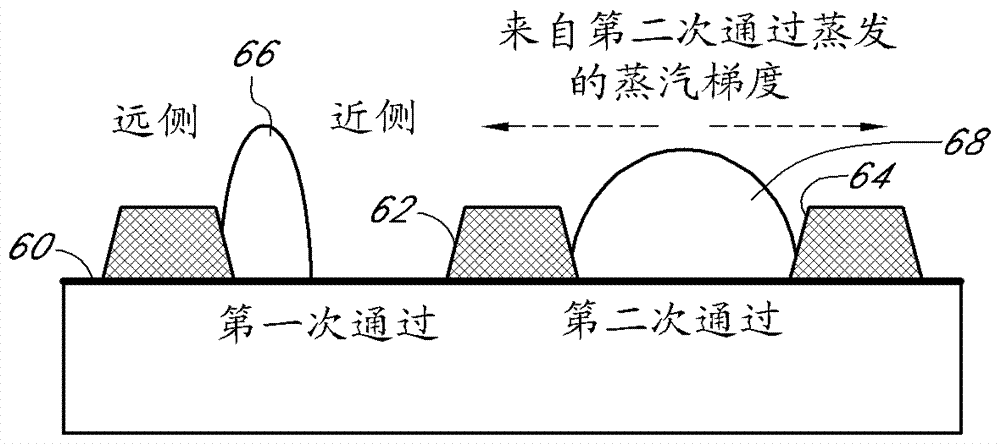

[0057] The present teachings relate to discovering and solving troublesome problems faced by printing with various inks on substrates. The problem involves a phenomenon referred to herein as "stacking". Stacking may occur when a first region of pixels is printed on a substrate and then a second adjacent region is printed on the same substrate. At the interface between these two zones, a row of pixels in the first print zone may experience stacking, that is, ink remains at one end of the pixel bank compared to at the opposite end of the pixel bank. There is more ink that dries this way. As a result, non-uniform pixels are produced. can refer to Figure 1A , 1B and 1C to better understand this phenomenon.

[0058] Figure 1A is a top view of a schematic representation of substrate 40 . The substrate 40 is shown divided into two zones, a first zone 42 and a second zone 44 , the interface of which is a boundary 43 . Pixel banks 48 are shown in the first row of pixel banks 46...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com