A kind of corn yeast bread and its preparation process

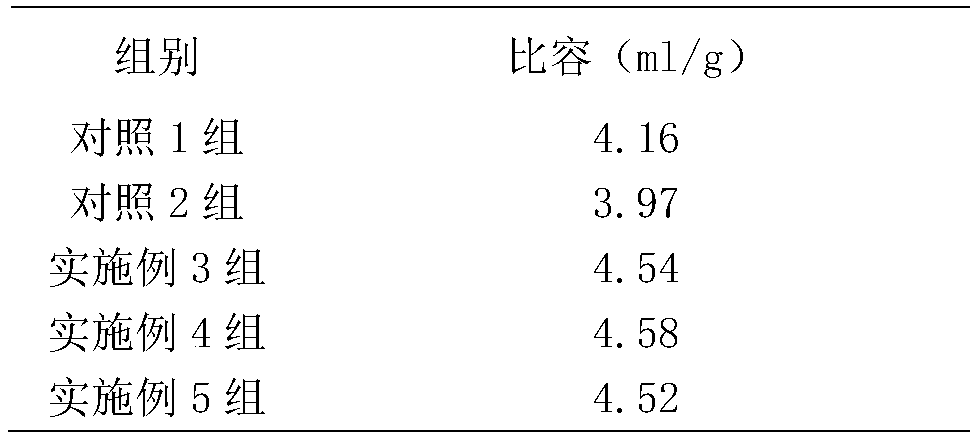

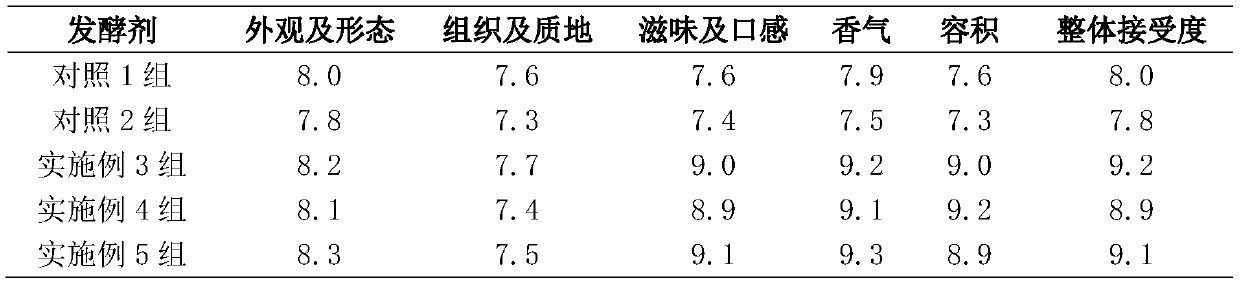

A preparation process and yeast technology, applied to the field of corn yeast bread and its preparation, can solve the problems of insufficient bread flavor, single bread taste, low softness and the like, and achieve the effects of large specific volume, full volume and strong aroma.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] prescription:

[0028] 500 parts of high-gluten flour, 15 parts of corn yeast, 90 parts of white sugar, 4 parts of salt,

[0029] 90 parts of egg liquid, 65 parts of shortening, and 170 parts of water.

[0030] Wherein the corn yeast is made by the following methods:

[0031] After mixing flour and cornflour with a ratio of 250:100 by weight, add hot water equivalent to twice the amount of flour to the flour and cornflour to boil, stir until there are no lumps, then cool to room temperature for fermentation, summer fermentation 2 days, 5 days of fermentation in winter. After the fermentation is completed, it is patted into a cake shape, and the finished corn yeast can be obtained after drying.

[0032] Preparation Process:

[0033] 1. Raw material weighing: weigh various raw materials according to the formula;

[0034] 2. Corn yeast activation: Weigh the corn yeast, add 2 times the weight of water and soak at room temperature for 25 minutes;

[0035] 3. Stir evenl...

Embodiment 2

[0041] prescription:

[0042] 500 parts of high-gluten flour, 25 parts of corn yeast, 110 parts of white sugar, 6 parts of salt,

[0043] 110 parts of egg liquid, 85 parts of shortening, and 200 parts of water.

[0044] Wherein the corn yeast is made by the following methods:

[0045] After mixing flour and cornflour with a ratio of 350:100 by weight, add hot water equivalent to 3 times the amount of flour to the flour and cornflour and boil them, stir until there are no lumps, cool to room temperature for fermentation, and ferment in summer for 2 days, 5 days of fermentation in winter. After the fermentation is completed, it is patted into a cake shape, and the finished corn yeast can be obtained after drying.

[0046] Preparation Process:

[0047] 1. Raw material weighing: weigh various raw materials according to the formula;

[0048] 2. Corn yeast activation: Weigh the corn yeast, add 3 times the weight of water and soak at room temperature for 35 minutes;

[0049] 3....

Embodiment 3

[0055] prescription:

[0056] 500 parts of high-gluten flour, 20 parts of corn yeast, 100 parts of white sugar, 5 parts of salt,

[0057] 100 parts of egg liquid, 75 parts of shortening, and 187.5 parts of water.

[0058] Wherein the corn yeast is made by the following methods:

[0059] After mixing flour and cornflour with a ratio of 300:100 by weight, add hot water equivalent to 2.5 times the amount of flour to the flour and cornflour and boil them, stir until there are no lumps, then cool to room temperature for fermentation, summer fermentation 2 days, 5 days of fermentation in winter. After the fermentation is completed, it is patted into a cake shape, and the finished corn yeast can be obtained after drying.

[0060] Preparation Process:

[0061] 1. Raw material weighing: weigh various raw materials according to the formula;

[0062]2. Corn yeast activation: Weigh the corn yeast, add 2.5 times the weight of water and soak at room temperature for 30 minutes;

[0063...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com