Ultra-precision in-situ measurement device based on flexible probe and ultra-precision processing method

An in-situ measurement and ultra-precise technology, applied in the direction of metal processing equipment, measuring/indicating equipment, metal processing machinery parts, etc., can solve the obstacles to the integrated automation of processing, measurement and compensation processes, the system structure is not easy to miniaturize, and is not suitable for large Problems such as curvature and surface shape, to achieve the effect of ensuring offline measurement capability, breaking through the limitation of surface curvature measurement, and easy in-situ measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

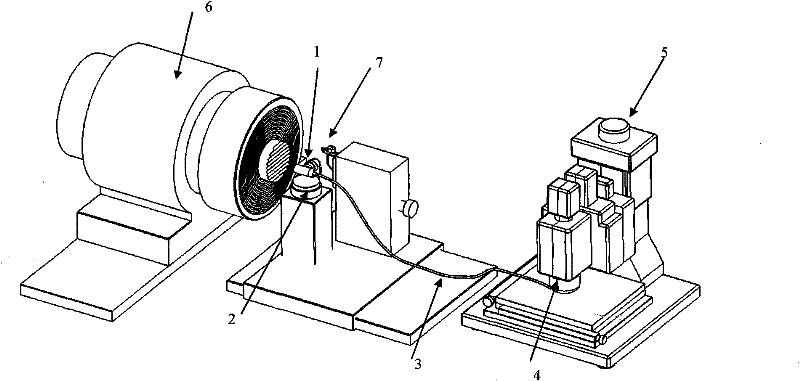

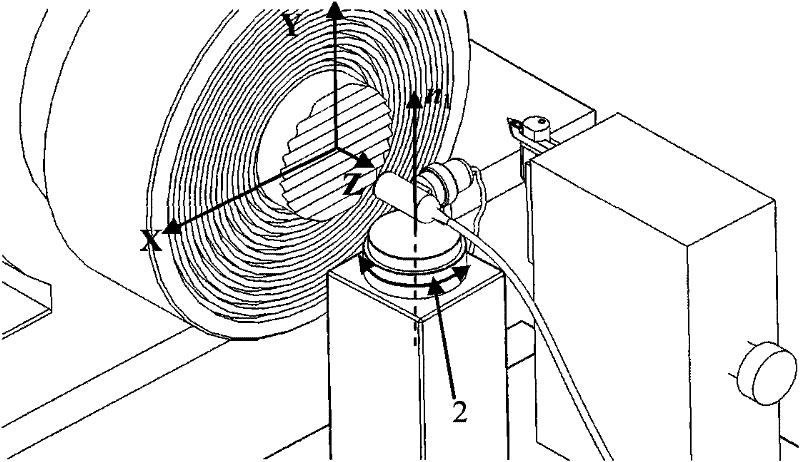

[0025] The invention proposes a flexible measuring head that can be directly placed on an ultra-precision machining machine tool to realize in-situ measurement of a large curvature surface. The measuring device equipped with this flexible measuring head includes: flexible measuring head, image transmission fiber, coupling mirror, optical three-dimensional measuring system, and high-precision turntable. The structure of its in situ measurement application is as follows figure 1 shown.

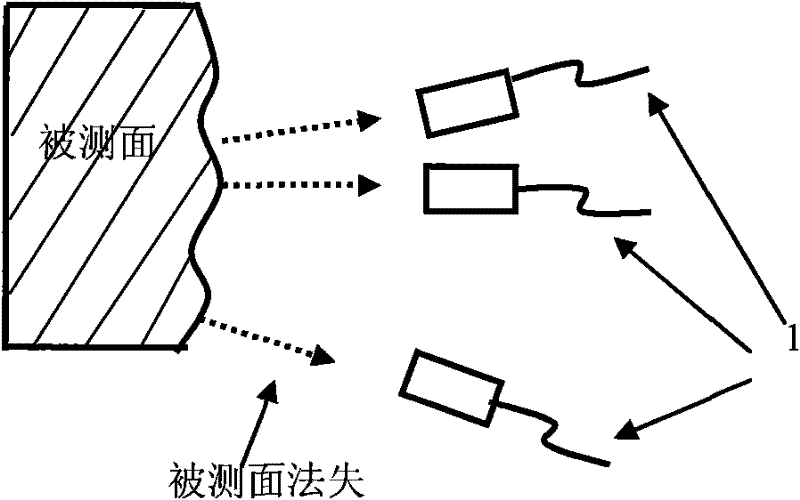

[0026] The optical measurement part of the probe is connected to the image transmission fiber by means of a coupling mirror, and the measured image is collected through the objective lens at the other end. The light can transmit the required light source illumination to the surface of the object to be measured, and at the same time transmit the measurement image modulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com