Semiautomatic hanger of container

A container and hanger technology, which is applied in the field of container supporting equipment, can solve the problems of container hangers such as cumbersome operation, reduced work efficiency, and short service life, and achieve the effects of automatic mechanical operation, extended service life, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

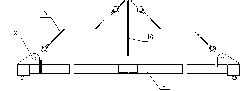

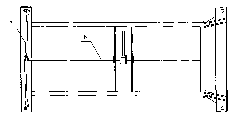

[0013] Such as figure 1 and figure 2 As shown, the container semi-automatic hanger of the present invention mainly includes a frame 1, a lifting lug 2, a steel wire rope 3, a lock 4, a lock adjuster, a pin 6, a connecting rod 7, and a lock swing arm 8; wherein:

[0014] The frame 1 corresponds to the shape of the upper surface of the container. The upper four corners of the frame 1 are equipped with lugs 2 for connecting the steel wire rope 3. The steel wire rope 3 is connected to the hook of the crane. The top of the lock head 4 has a dead bolt, and the horizontal section of the dead bolt can be a rectangle. When the lock head rotates to a position matching the container lock hole, after the hanger is put down, the dead bolt can pass through the lock hole, and then the lock head rotates to a position, such as After 90 degrees, the lock bolt is restricted by the end face of the container lock hole and cannot be pulled out, that is, it is in a locked state, so that after the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com