Two-stage beveled supersonic speed air inlet lip

A supersonic, oblique cutting technique applied to turbine/propulsion air intakes, combustion air/combustion-air handling, engine components, etc., to reduce buildup, improve flow, and reduce drag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The invention will be described more fully hereinafter with reference to the accompanying drawings, each of which shows an example of the application of the invention. The angle parameters marked in the figure are only for this application example. It should not be construed that the invention is limited to the application examples described here, but the invention can be embodied in many different forms.

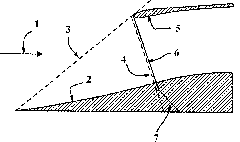

[0026] figure 1 A schematic diagram of the entrance wave system and lip position of a supersonic inlet without a partition using two-stage chamfered lips is shown. The supersonic incoming flow 1 produces a conical shock wave 3 under the action of the bulge compression surface 2, which forms a normal shock wave 4 before the entrance, and the inner surface 5 of the lip is consistent with the surface inclination angle of the bulge compression surface 2 at the entrance position. The sweep angle of the first-stage chamfered lip 6 is consistent with the angle of the norm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com