Method for correcting fuel calorific capacity of coal-fired boiler in real time

A coal-fired boiler, real-time correction technology, applied in the combustion method, adjusting the fuel supply, controlling the combustion and other directions, can solve the manual input lag, difficult to accurately distinguish the dynamic and static components of the load command changes in coal quality, and the coal quality cannot be online Measurement and other problems to achieve the effect of overcoming strong influence, overcoming stability and economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

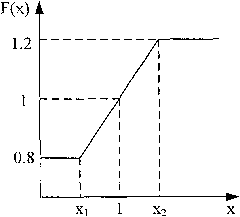

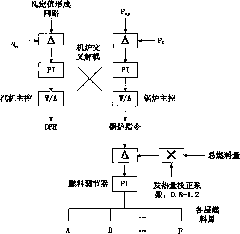

[0027] The invention provides a method for real-time correction of fuel calorific value of a coal-fired boiler, which includes firstly determining whether the coal-fired boiler is in a stable working condition, determining the coal quality working ability coefficient, and calculating the correction coefficient of the fuel calorific value in real time. Perform real-time correction to obtain the total fuel quantity that reflects the change of fuel coal quality in real time. The implementation of the real-time correction method for fuel calorific value of large coal-fired boilers includes the following main steps:

[0028] 1) Control system configuration

[0029] according to figure 1 The configuration control system shown. The difference between the actual load of the unit and the load command of the unit and the difference between the main steam pressure and the set value of the main steam pressure are respectively passed through the high and low limit alarm (the high and low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com