Application of double-layer vacuum time-delay leak detection technique in large capacity injection

A double-layer vacuum, large-capacity technology, applied in the direction of using liquid/vacuum for liquid tightness measurement, etc., can solve problems such as deterioration of liquid medicine, physical harm to patients, and influence on stability of liquid medicine, so as to ensure physical health and reduce Medical malpractice, the effect of reducing microleakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

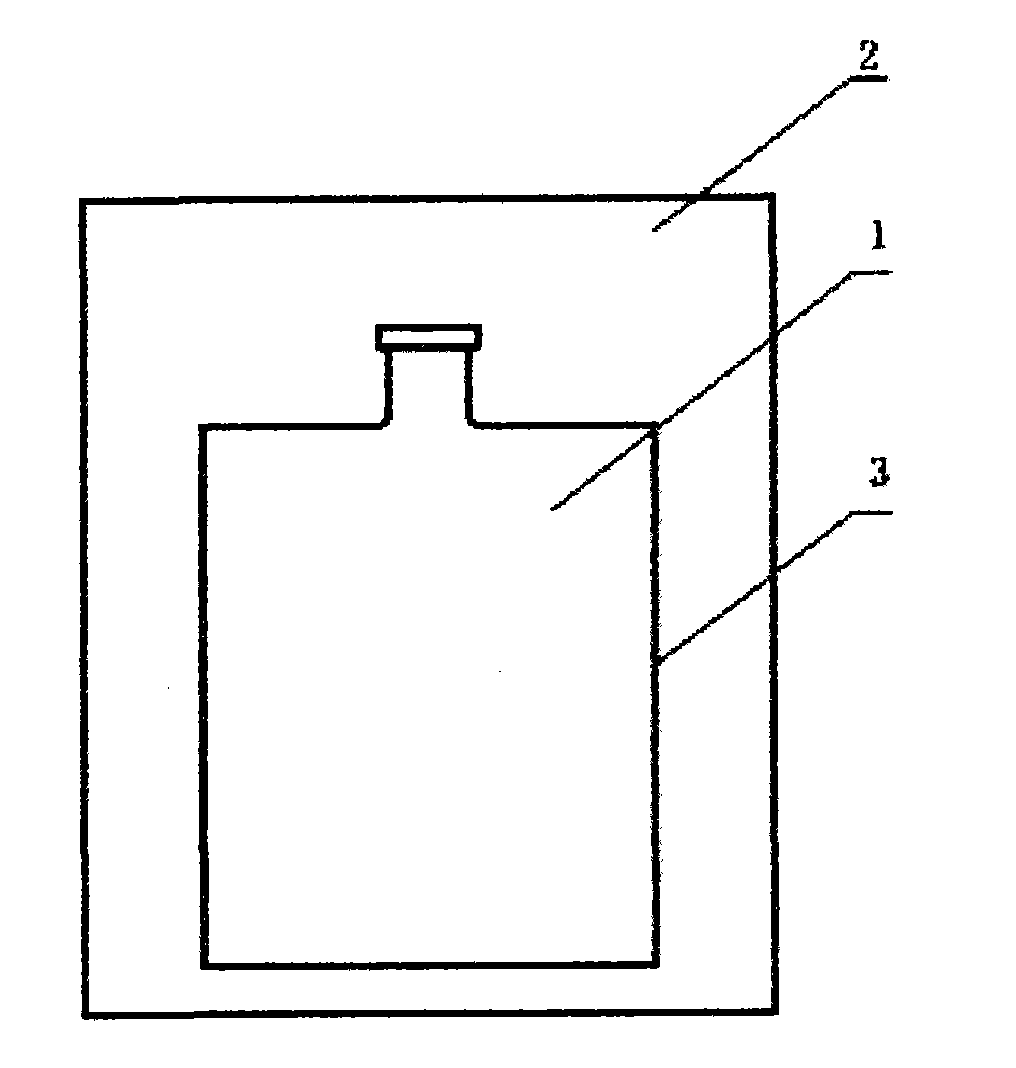

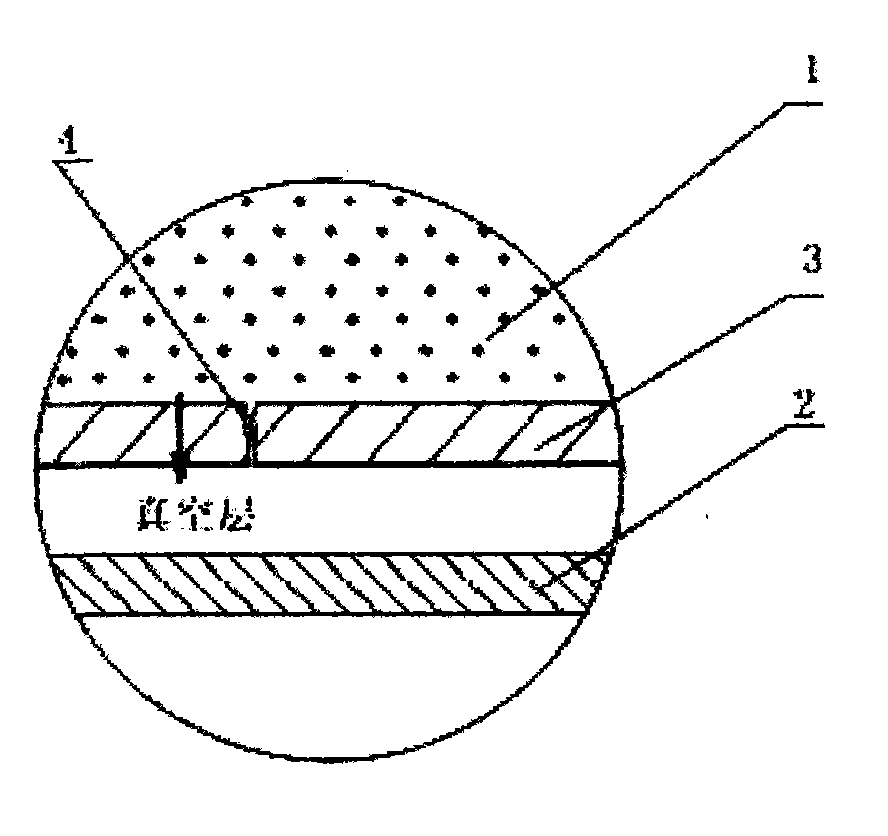

[0029] Among the large-capacity injections, including glass bottle infusion, plastic bottle infusion, soft bag infusion and upright infusion bag, the infusion bag can be packed vertically. At present, glass bottle infusion is the most produced in China, but because of the large capacity of soft bag infusion Injection can ensure its safety and sanitation more, and will occupy the main market of large-capacity injection, so this embodiment focuses on soft bag infusion large-capacity injection for elaboration.

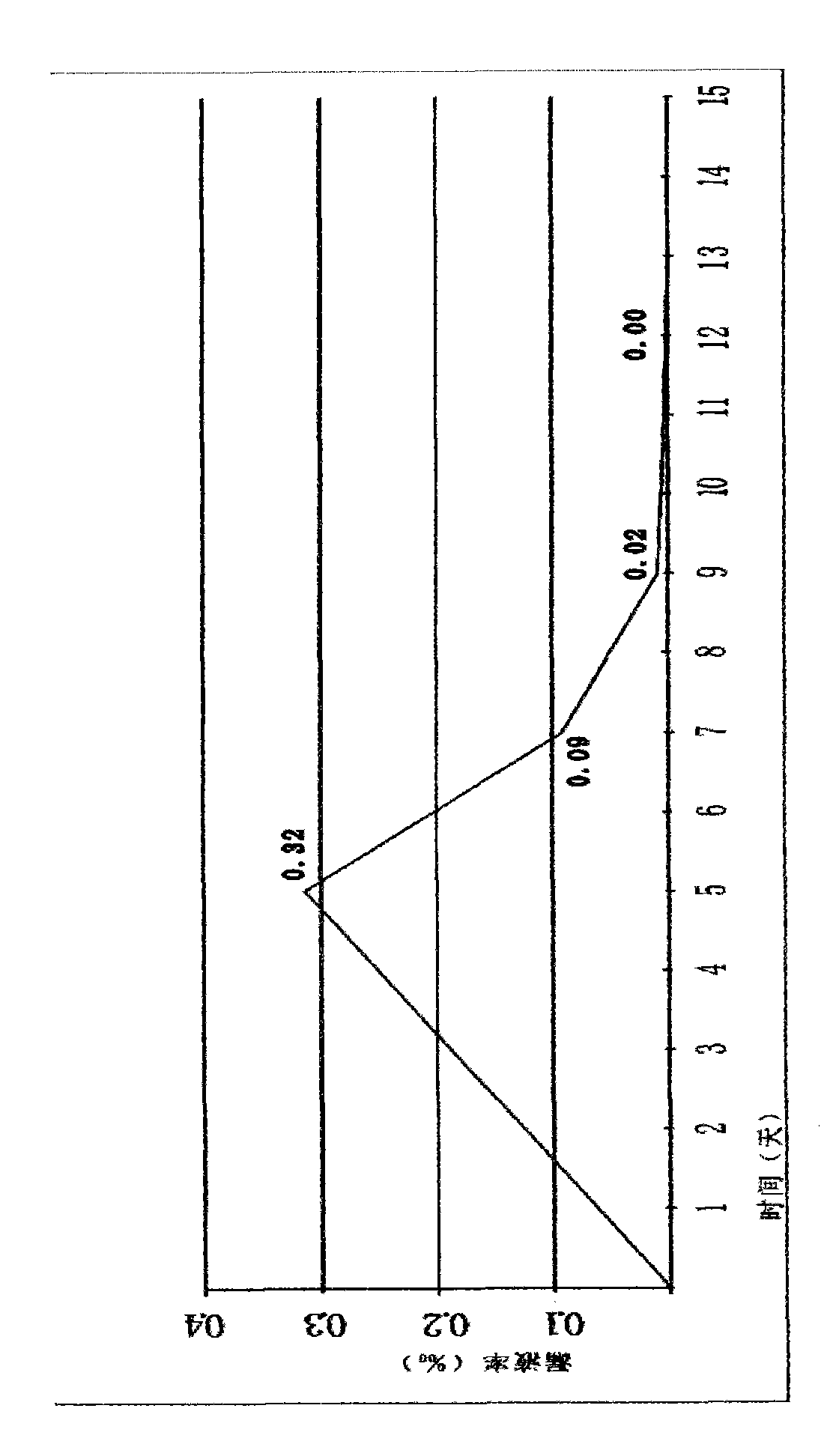

[0030] The production process of the soft bag infusion is as follows: first cut the film material (packaging material), then heat seal the film material on three sides (sides), and then weld the infusion port tube on the other side (filling the medicine while welding) Solution 1), in the above process, the heat sealing process of the three sides and the welding process of welding the infusion port tube, due to the uncertain factors of the process technology, it is very lik...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com