Online and rapid leakage detecting method for roller hearth type non-oxidation furnace radiating pipe

A technology without oxidation furnace and radiant tube, which can be used in the direction of measuring the acceleration and deceleration rate of fluid and using liquid/vacuum degree for liquid tightness measurement, which can solve the problems of radiation tube leakage and difficulty in simultaneous detection, and reduce labor intensity. , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

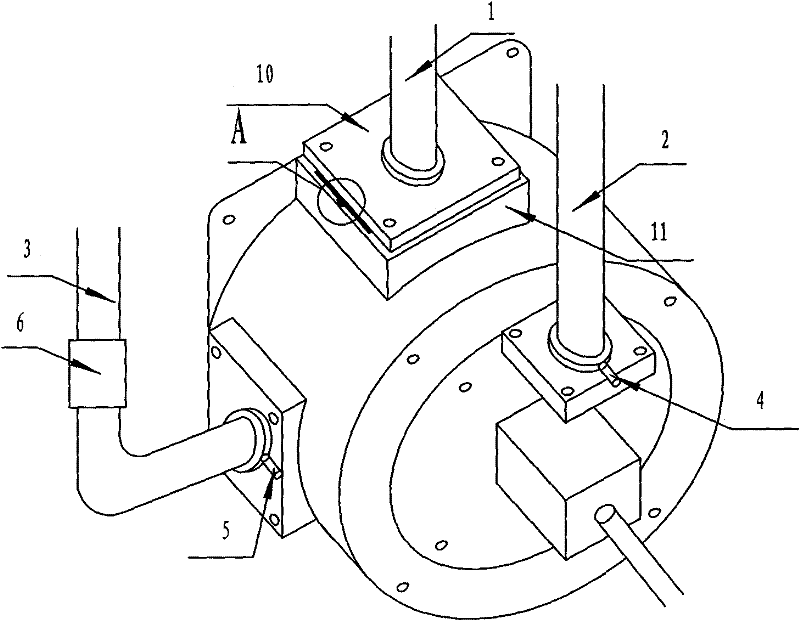

[0019] The installation of this embodiment is as follows figure 1 As shown, a roller hearth type non-oxidizing furnace radiant tube online rapid leak detection method is carried out according to the following steps:

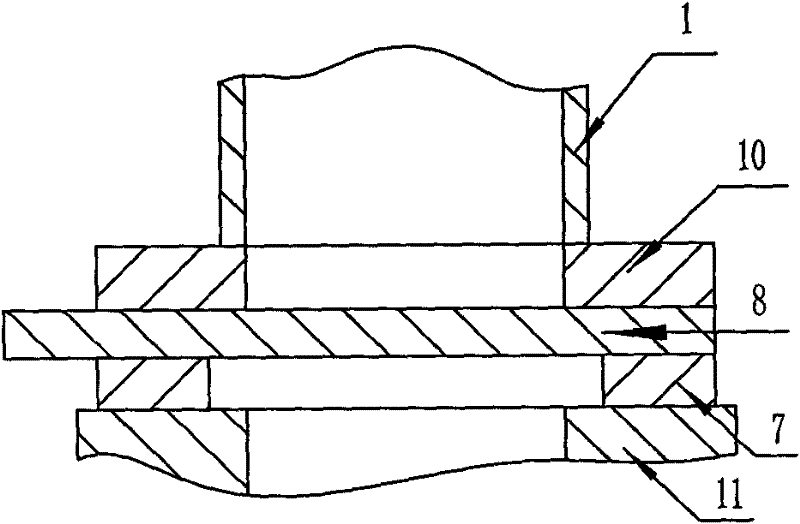

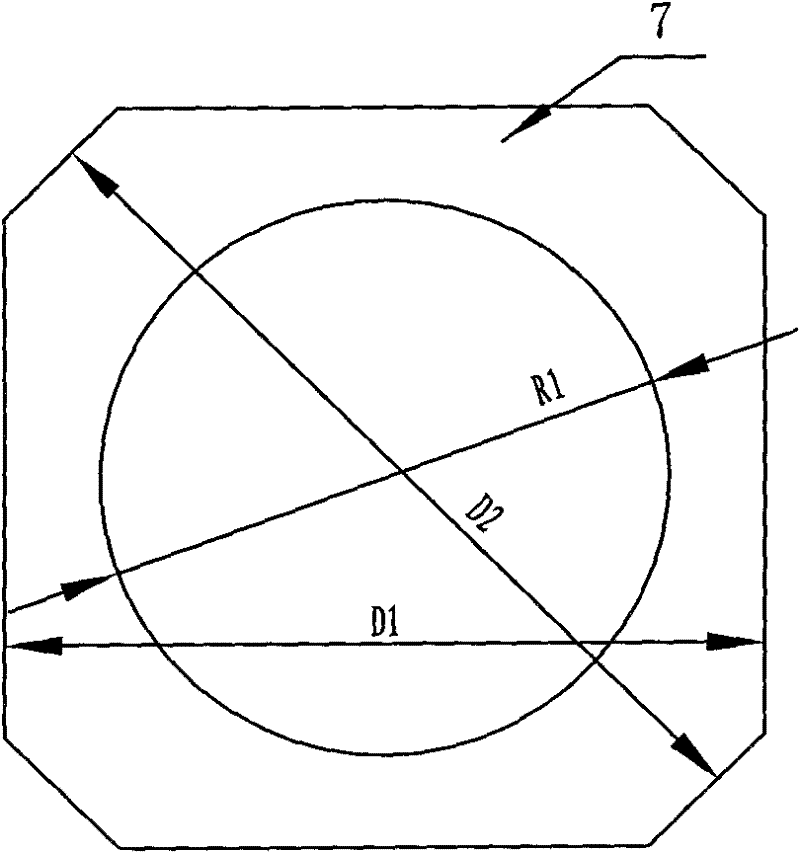

[0020] (1) According to the external dimensions of the flange mouth at the connection between the burner body and the exhaust gas pipe 1, use asbestos pads to make the gasket 7 that matches the flange, and use tinplate to make the explosion-proof disc 8; the structure of the gasket 7 is as follows image 3 As shown, the diameter R1 of the inner hole of the gasket 7 is equal to the inner diameter of the flange, the width D1 of the gasket 7 does not exceed the outer diameter of the flange, and the diagonal width D2 of the gasket 7 does not exceed the position of the bolt hole; the structure of the explosion-proof disc 8 is as follows Figure 4 As shown, the explosion-proof disk 8 is a circular explosion-proof disk with a protruding part 9, and the outer diameter R2...

Embodiment 2

[0026] The installation of this embodiment is as follows figure 1 As shown, a roller hearth type non-oxidizing furnace radiant tube online rapid leak detection method is carried out according to the following steps:

[0027] (1) According to the external dimensions of the flange mouth at the connection between the burner body and the exhaust gas pipe 1, use asbestos pads to make the gasket 7 that matches the flange, and use tinplate to make the explosion-proof disc 8; the structure of the gasket 7 is as follows image 3 As shown, the diameter R1 of the inner hole of the gasket 7 is equal to the inner diameter of the flange, the width D1 of the gasket 7 does not exceed the outer diameter of the flange, and the diagonal width D2 of the gasket 7 does not exceed the position of the bolt hole; the structure of the explosion-proof disc 8 is as follows Figure 4 As shown, the explosion-proof disk 8 is a circular explosion-proof disk with a protruding part 9, and the outer diameter R2...

Embodiment 3

[0033] The installation of this embodiment is as follows figure 1 As shown, a roller hearth type non-oxidizing furnace radiant tube online rapid leak detection method is carried out according to the following steps:

[0034] (1) According to the external dimensions of the flange mouth at the connection between the burner body and the exhaust gas pipe 1, use asbestos pads to make the gasket 7 that matches the flange, and use tinplate to make the explosion-proof disc 8; the structure of the gasket 7 is as follows image 3 As shown, the diameter R1 of the inner hole of the gasket 7 is equal to the inner diameter of the flange, the width D1 of the gasket 7 does not exceed the outer diameter of the flange, and the diagonal width D2 of the gasket 7 does not exceed the position of the bolt hole; the structure of the explosion-proof disc 8 is as follows Figure 4 As shown, the explosion-proof disk 8 is a circular explosion-proof disk with a protruding part 9, and the outer diameter R2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com