Online leakage detection method and device thereof for heat treatment furnace radiant tube

A technology of heat treatment furnace and radiant tube, which is applied in the direction of measuring the acceleration and deceleration rate of fluid, using liquid/vacuum degree for liquid tightness measurement, etc. Improved accuracy and reliability, shorter test cycles, and less labor-intensive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

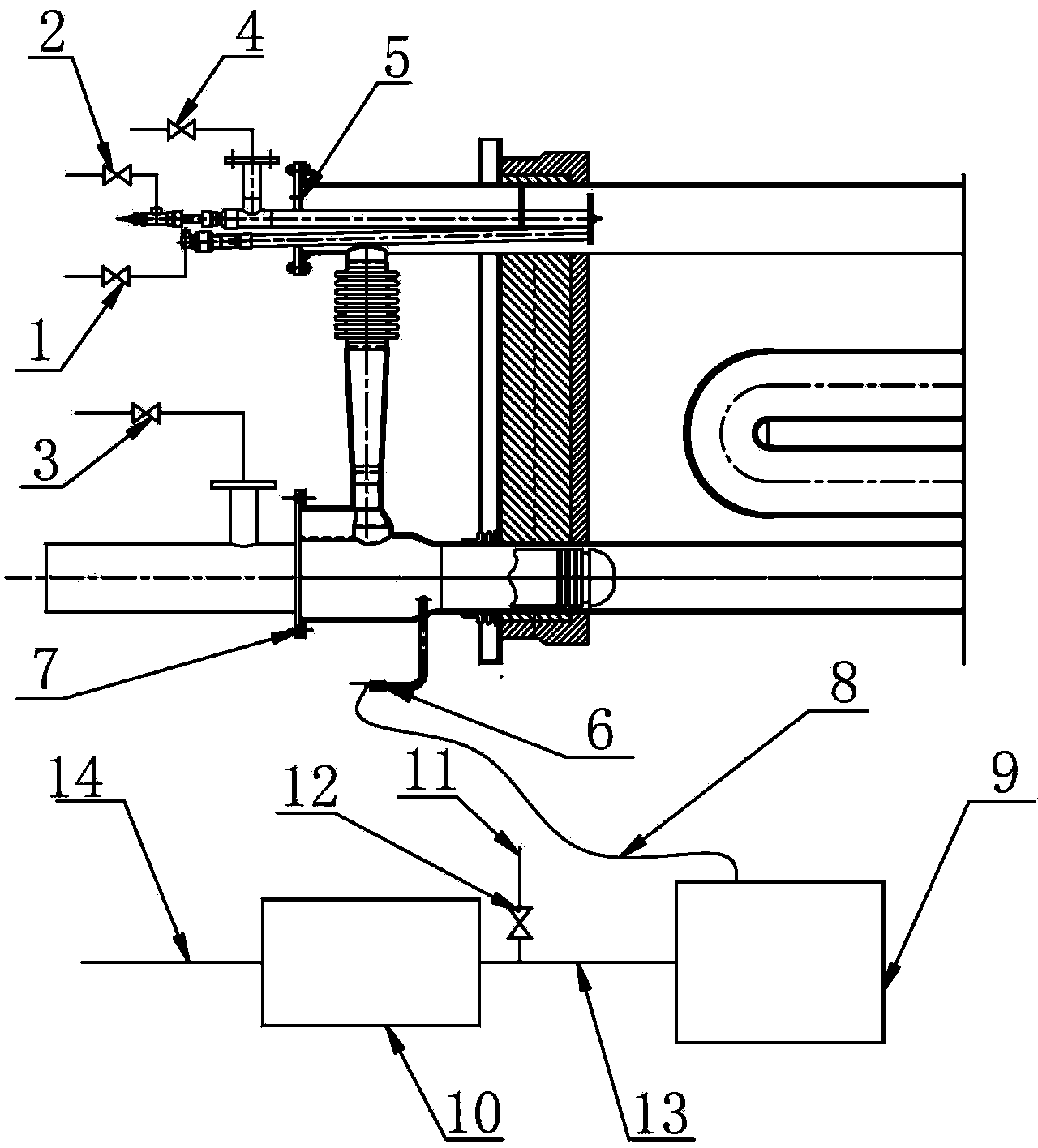

[0026] Such as figure 1 A heat treatment furnace radiant tube online leak detection device shown includes a gas flowmeter 9 and a vacuum sampling pump 10, the gas inlet of the gas flowmeter 9 is connected to one end of the gas sampling pipe 8, and the other end of the gas sampling pipe 8 is used In connection with the sampling head 6 of the radiant tube burner, the exhaust port of the gas flow meter 9 is connected with one end of the gas suction pipe 13 , and the other end of the gas suction pipe 13 is connected with the intake end of the vacuum sampling pump 10 . The gas suction pipe 13 is provided with a protection branch pipe 11 communicating with the atmosphere, the protection branch pipe 11 is provided with an on-off valve 12 , and the gas outlet end of the vacuum sampling pump 10 is provided with a waste gas outlet pipe 14 .

[0027] When the above device performs on-line leak detection of the radiant tube of the heat treatment furnace, the following steps are included: ...

Embodiment 2

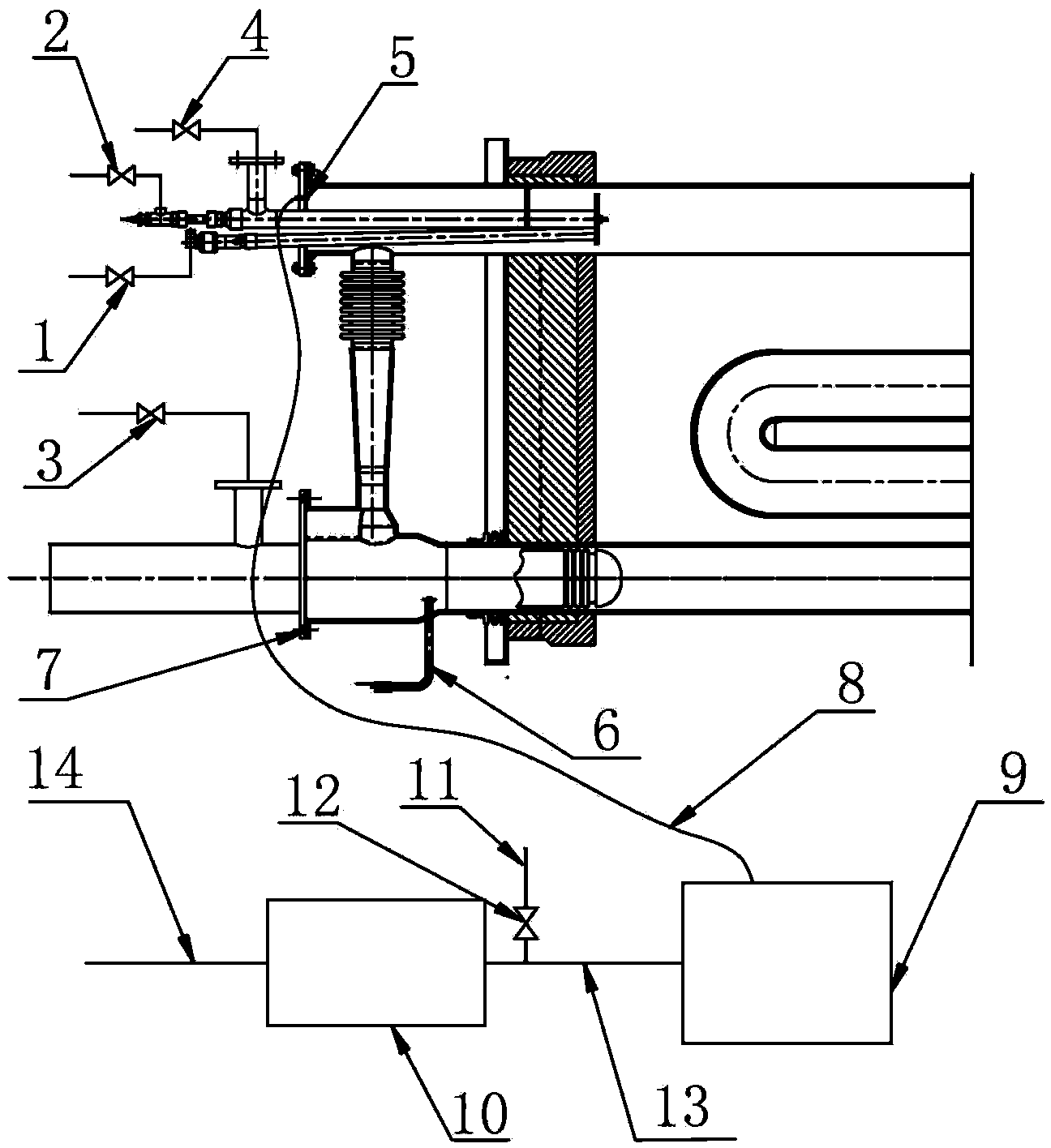

[0032] Such as figure 2 Another heat treatment furnace radiant tube online leak detection device shown includes a gas flowmeter 9 and a vacuum sampling pump 10. The gas inlet of the gas flowmeter 9 is connected to one end of the gas sampling pipe 8, and the other end of the gas sampling pipe 8 is It is used to connect the pressure measuring nozzle 5 on the end face of the radiant tube burner. The exhaust port of the gas flowmeter 9 is connected to one end of the gas suction pipe 13 , and the other end of the gas suction pipe 13 is connected to the intake end of the vacuum sampling pump 10 . The gas suction pipe 13 is provided with a protection branch pipe 11 communicating with the atmosphere, the protection branch pipe 11 is provided with an on-off valve 12 , and the gas outlet end of the vacuum sampling pump 10 is provided with a waste gas outlet pipe 14 . The gas sampling pipe 8, the gas suction pipe 13 and the waste gas outlet pipe 14 can adopt flexible pipes or hard pipes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com