Novel large-power cavity separating type cabinet frame

A high-power, cabinet technology, applied in electrical equipment shell/cabinet/drawer, cooling/ventilation/heating transformation, circuit layout on support structure, etc. Occupation and other problems to achieve the effect of overcoming the difference in volume and solving the inefficiency of convection heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

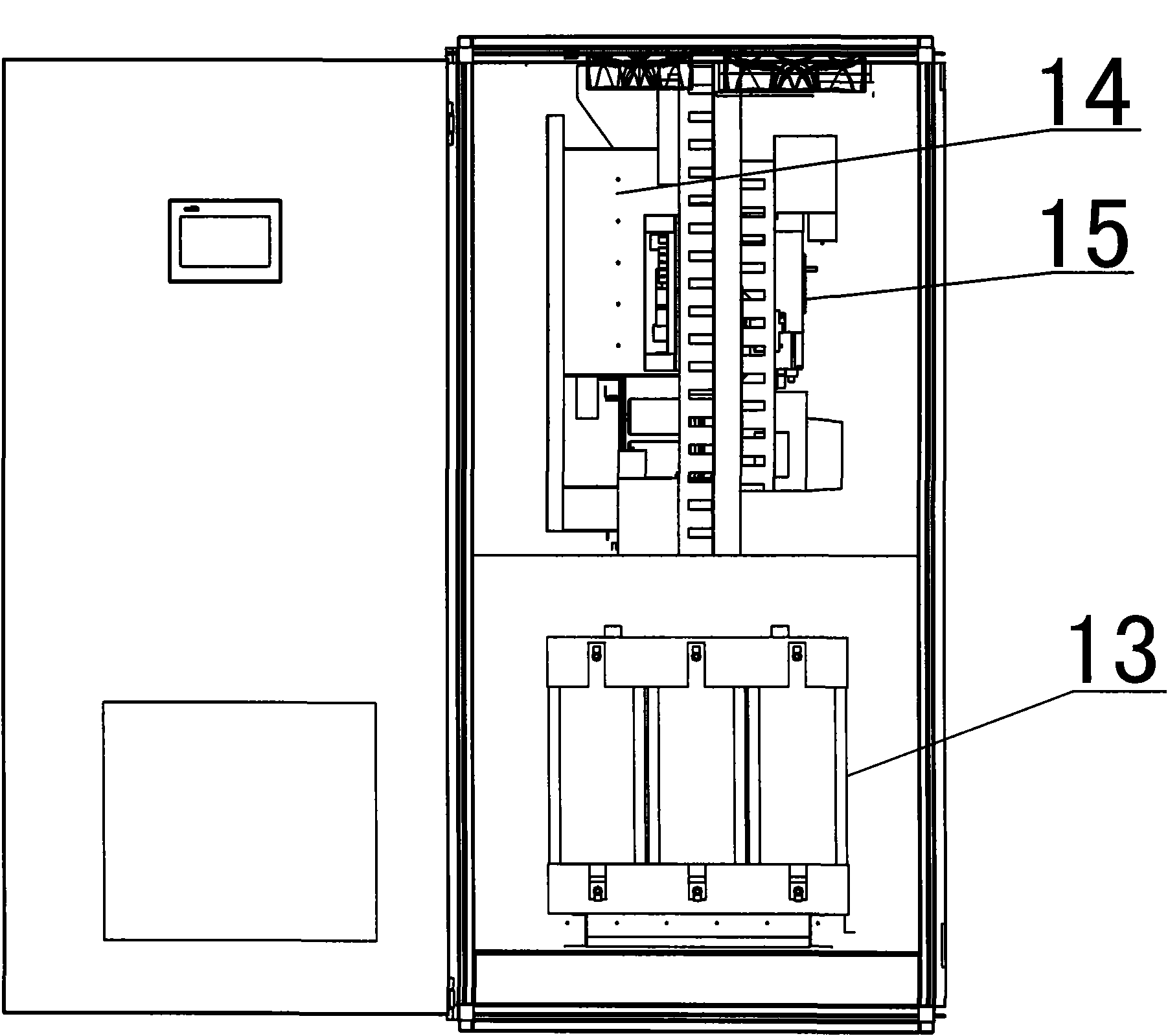

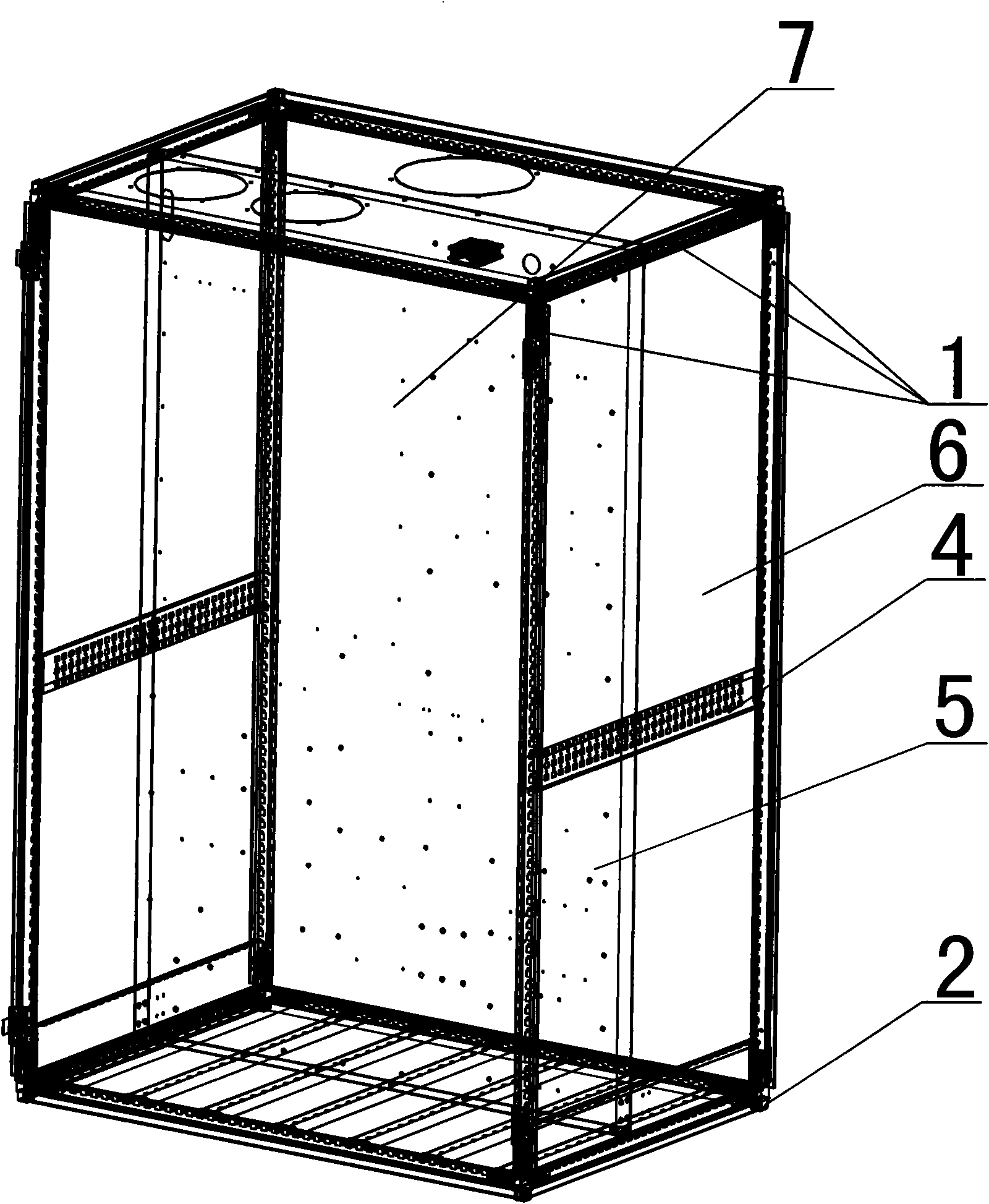

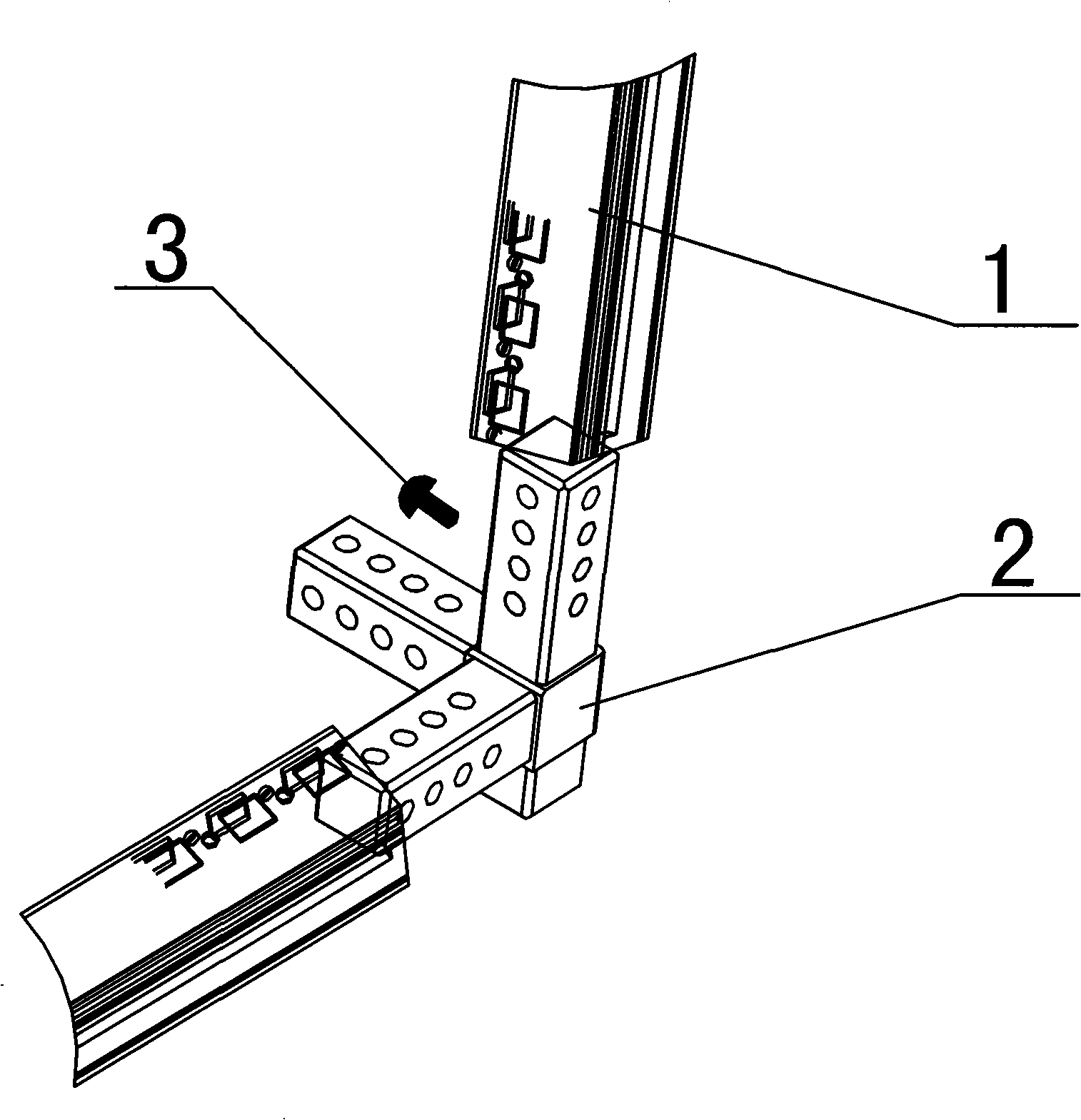

[0016] Such as Figure 1-6 As shown, the novel high-power sub-cavity cabinet frame of the present invention includes a cabinet frame body composed of twelve standard columns 1, triangular brackets 2 and M5 self-tapping screws 3. The middle part of the columns 1 passes through M5 self-tapping screws 3 are fixed on the steel beam 4, and the inner cavity of the frame is vertically laid with a 2mm-thick middle partition 5, which is respectively locked on four steel beams 4 parallel to the Y direction by M5 self-tapping screws 3 and inside the cabinet. Two independent electrical cavities are formed, that is, the electromagnetic cavity 6 and the electrical functional cavity 7; the bottom end of the column 1 is provided with a triangular bracket 2 and connected to the adjacent column 1 through the bracket. The electromagnetic cavity 6 is used to install magnetic elements 13, and the electrical function cavity 7 is used to install high-power consumption electrical module components 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com