Process for producing liquid developer

A manufacturing method and developer technology, applied in developer, electrography, optics, etc., can solve problems such as inability to obtain image quality, deterioration of charging characteristics and electrophoretic properties of colored resin particles, and coarse particles

Inactive Publication Date: 2010-08-18

SAKATA INX

View PDF9 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

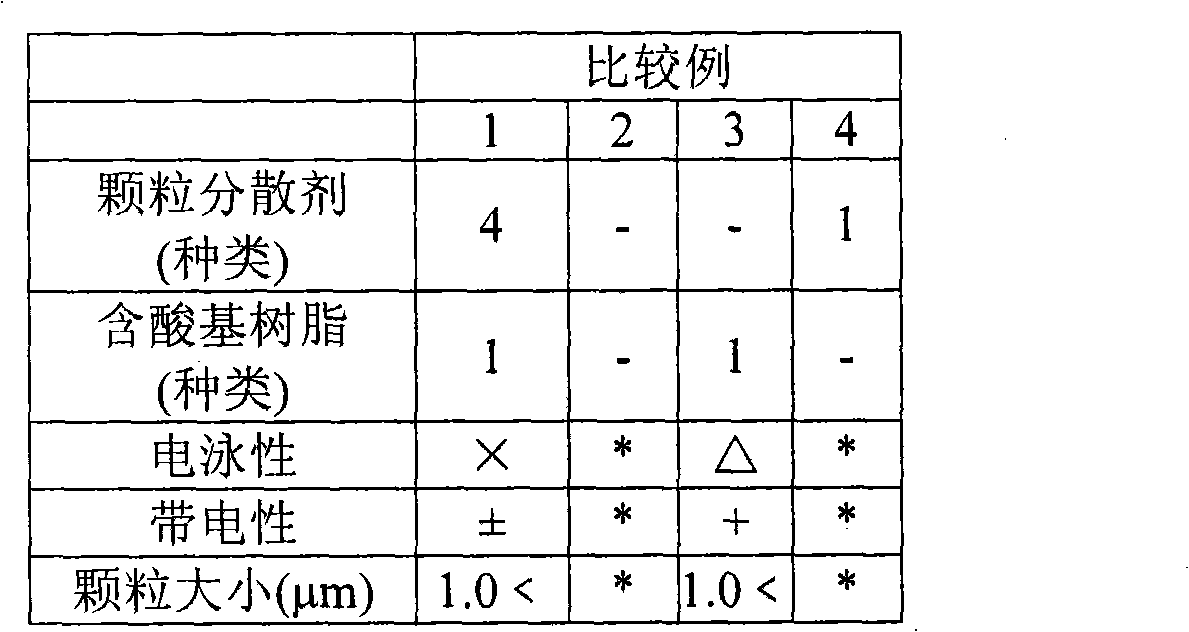

However, in the agglomeration method, there is a problem that the coloring resin particles tend to aggregate when the resin is precipitated, making the particles coarse, etc., resulting in insufficient dispersion stability and optical properties of the obtained developer.

These compounds are not materials designed with emphasis on the dispersibility of the particles, so the effect of sufficiently improving the dispersibility of the fine colored resin particles cannot be expected

In addition, from the viewpoint of the compatibility of the liquid developer, there is a problem that the charging characteristics and electrophoretic properties of the colored resin particles are deteriorated, and good image quality cannot be obtained.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

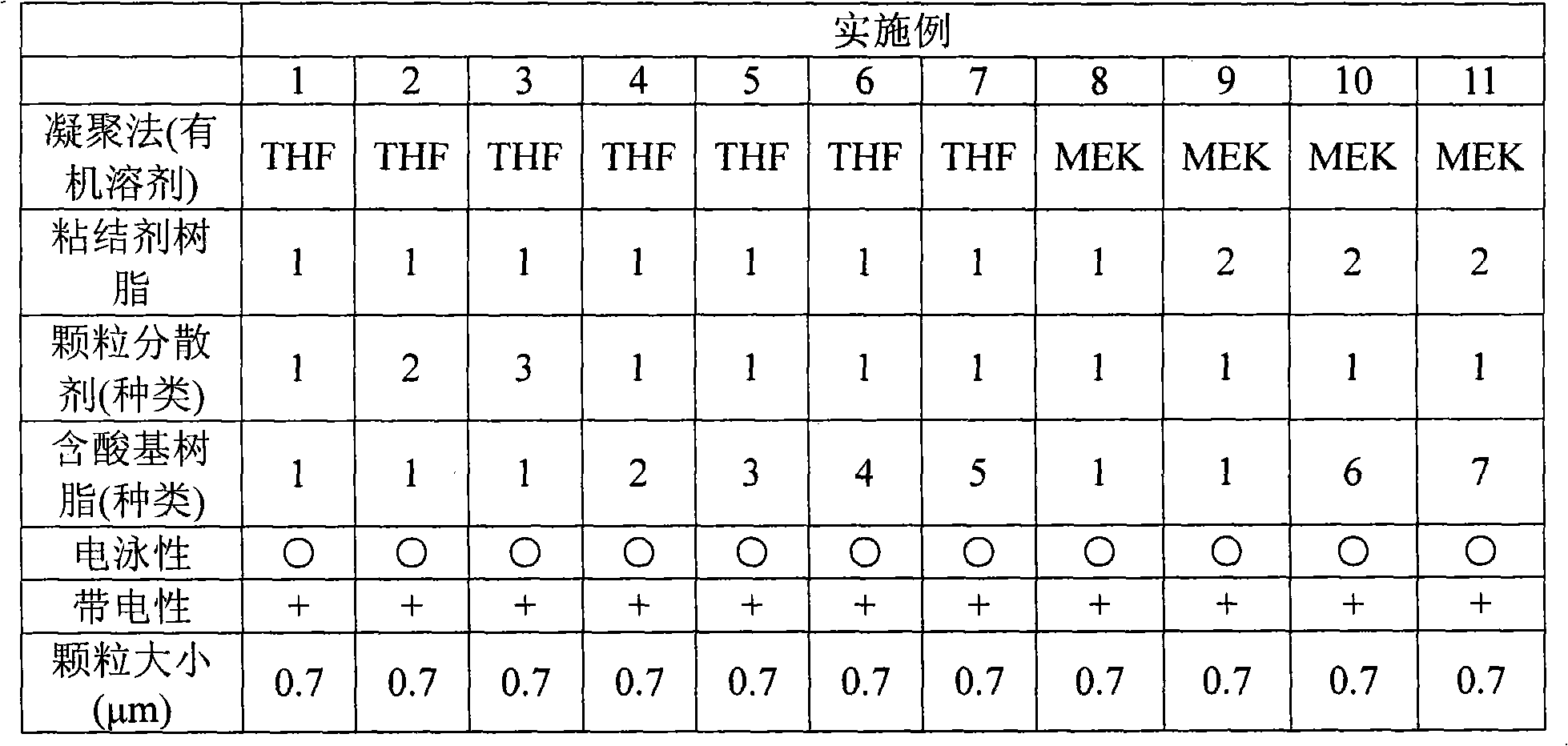

This invention provides a process for producing a liquid developer for electrophotography or electrostatic recording, produced by a coacervation method, which process can produce a liquid developer which can satisfactorily maintain charging characteristics of the liquid developer and has good dispersion stability of colored resin particles, and a liquid developer produced by the production process. The production process is a process for producing a liquid developer utilizing a coacervation method. In the production process, colored resin particles are dispersed in an insulating hydrocarbon dispersive medium in the presence of a particle dispersing agent, which is a reaction product between a polyamine compound and a self-condensation product of a hydroxycarboxylic acid, and an acid group-containing resin.

Description

technical field The present invention relates to a method for producing a liquid developer for electrophotography or electrostatic recording used in printing machines, copiers, printers, facsimile machines, etc., and a liquid developer obtained by the method. Background technique Among the liquid developers, those in the form of colored resin particles containing a colorant such as a pigment dispersed in an electrically insulating dispersion medium are generally used. In addition, as one of methods for producing such a liquid developer, there is an aggregation method (Coaselbe-Sion method). The coacervation method refers to a method in which the solvent is removed from a mixed solution of a resin-dissolving solvent and an electrically insulating dispersion medium that does not dissolve the resin, whereby the resin contained in the mixed solution in a dissolved state is precipitated in a state of enclosing a colorant, Thereby, the colored resin particles are dispersed in the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G03G9/12G03G9/13

CPCG03G9/131G03G9/1355G03G9/122G03G9/125G03G9/135

Inventor 前田宽仁冈本胜利淀贵明稻角直也岩瀬孝司

Owner SAKATA INX

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com