Vibratory shucking device

A vibrating body and vibrating plate technology, applied in the field of wire rod manufacturing, can solve the problems of large damage to the wire rod and the impact on the quality of the finished wire rod, and achieve the effects of reducing energy consumption, thorough peeling treatment, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

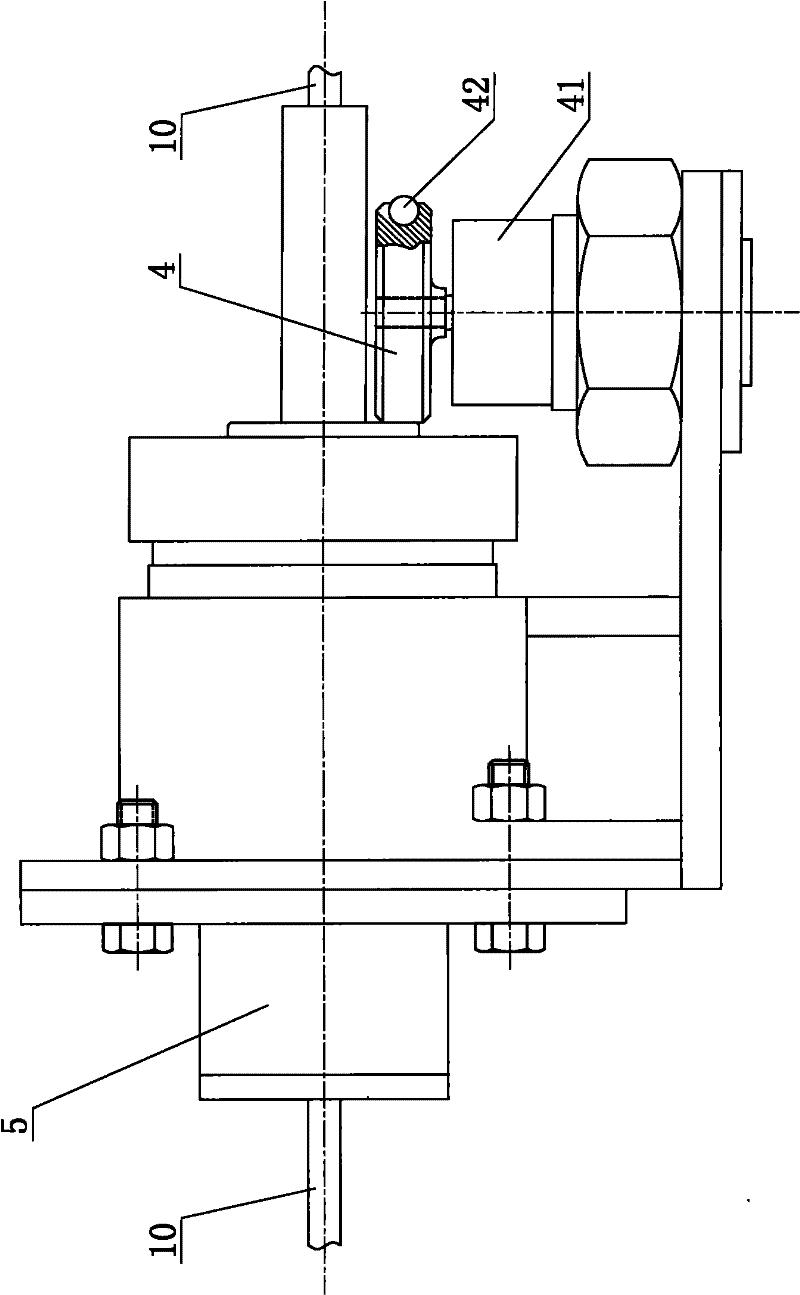

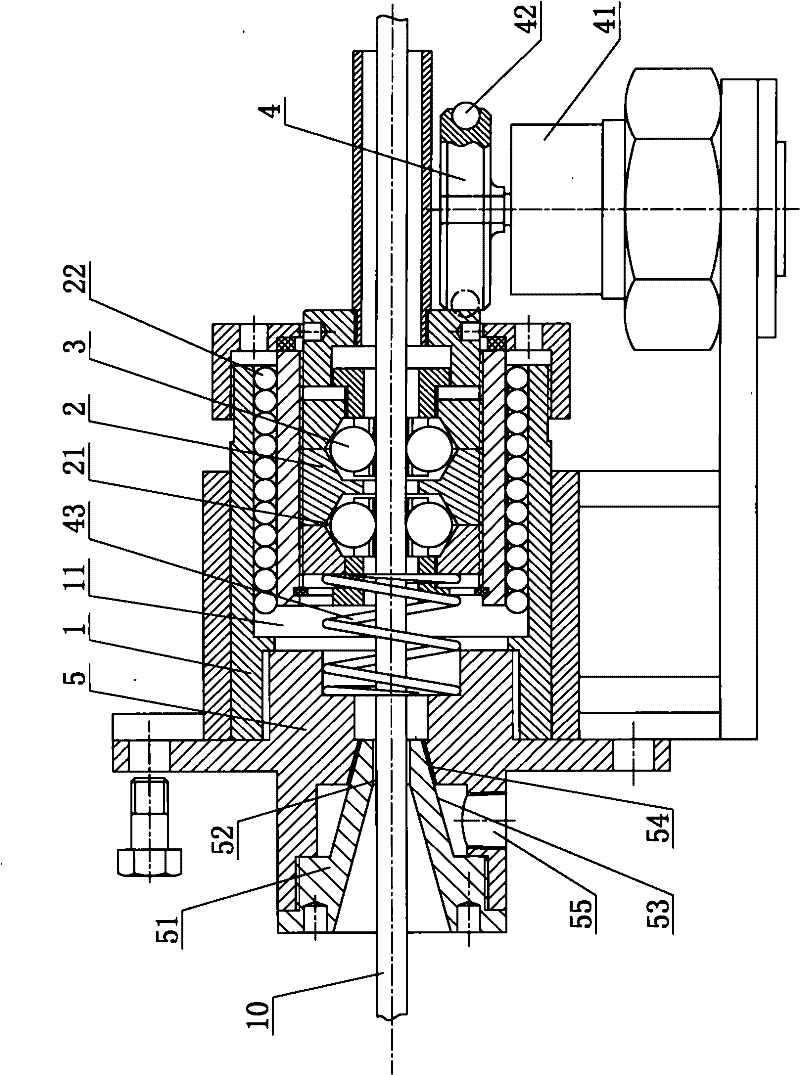

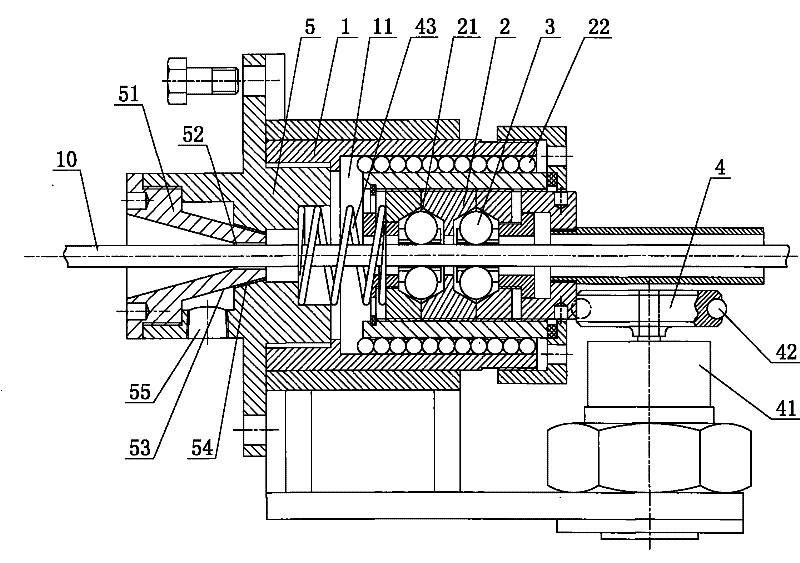

[0022] Such as Figures 1 to 2 The shown vibration peeling device comprises a base 1 and a vibrating body 2, the base 1 is provided with a through hole 11 for installing the vibrating body 2, and the vibrating body 2 is movably arranged at the right end of the through hole 11, and the vibrating body 2 The side is provided with a driving mechanism for driving the vibrating body 2 to do reciprocating motion; the middle part of the vibrating body 2 is provided with a wiring hole for the wire 10 to pass through, and the inner wall of the wiring hole is provided with a circular groove 21, and the circular groove A movable striking body 3 is arranged in the groove 21 . The vibrating peeling devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com