Non-oriented electrical sheet steel with good iron loss and manufacturing method thereof

A technology for an oriented electrical steel sheet and a manufacturing method, which is applied in the field of metallurgical steel sheets and their manufacturing, and achieves the effects of simple operation, low cost, and improved performance of the steel sheet

Inactive Publication Date: 2010-08-25

BAOSHAN IRON & STEEL CO LTD

View PDF4 Cites 29 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in the case where further cost reduction is required, it is difficult to sufficiently and stably produce non-oriented electrical steel sheets with excellent iron loss by the above method.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

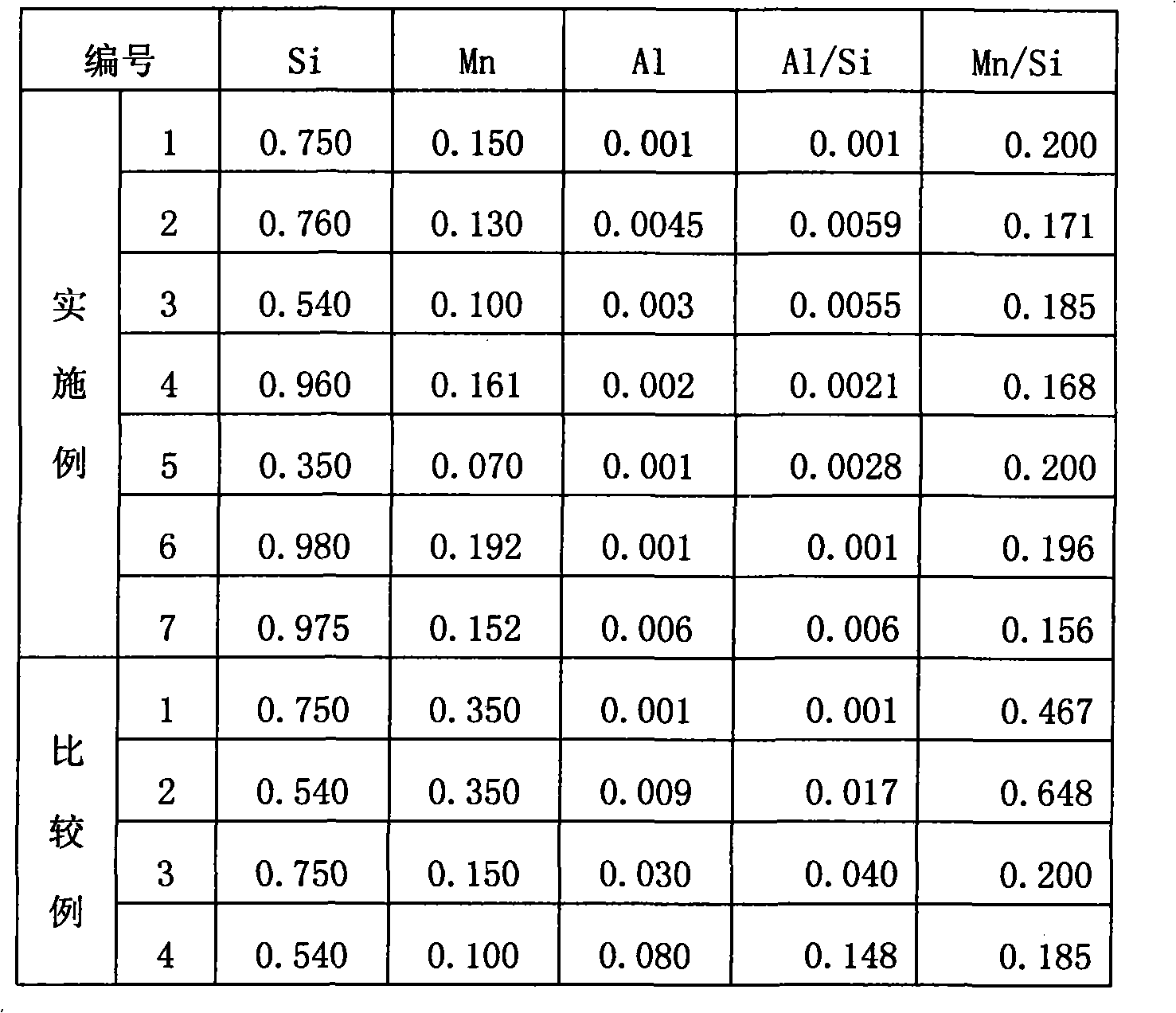

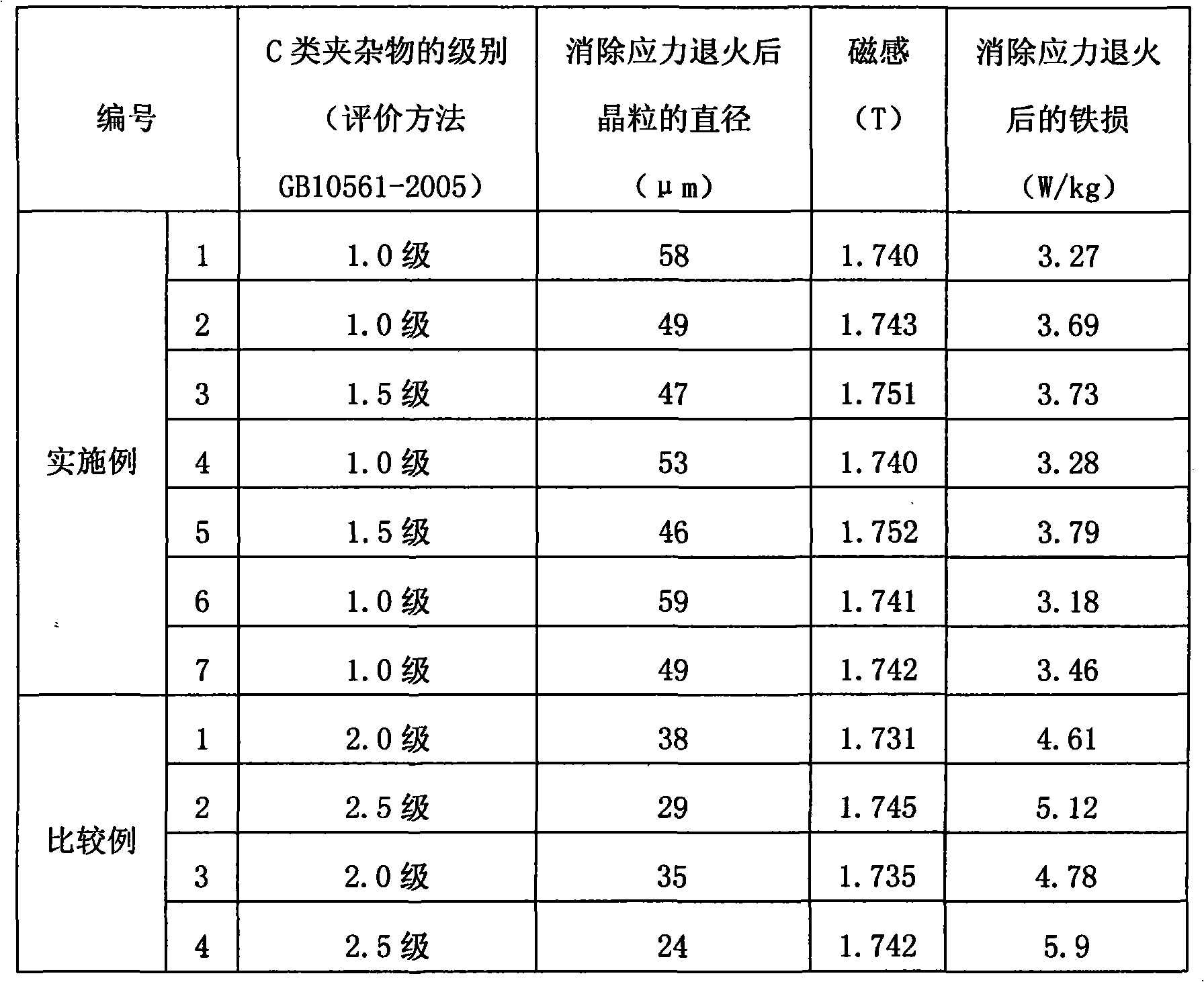

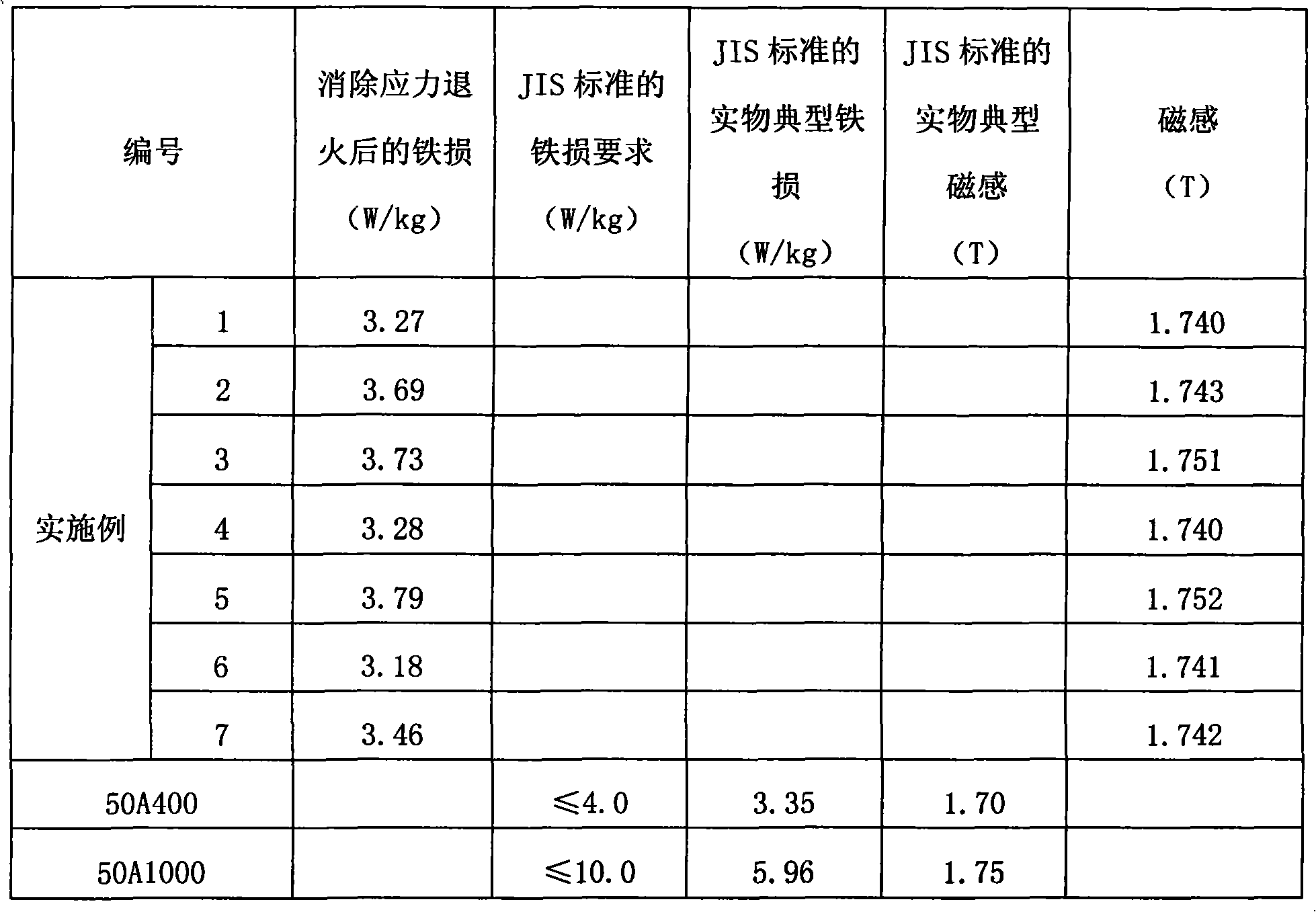

The invention provides a non-oriented electrical sheet steel with good iron loss, which is characterized in that the non-oriented electrical sheet steel with good iron loss comprises the following components in percentage by weight: C: <= 0.003%, Si: <=1.0%, Mn: <=0.20%, Al: <= 0.001-0.009%, S: <=0.004%, N: <=0.003%, Ti: <= 0.0020%, Al / Si: 0-0.006 and Mn / Si: 0-0.2, wherein the proportion of three element inclusion SiO2-Al2O3-MnO is as follows: SiO2: >=95%, Al2O3: 2-3% and MnO: <=2%, and the balance Fe and inevitable impurities. The invention also provides a manufacturing method for the steel. An optimal component range of Si, Mn and Al is set through research, the level of the oxidized inclusion and precipitates are controlled, growth of grains is promoted and the non-oriented electrical sheet steel with low iron loss is obtained.

Description

Non-oriented electrical steel sheet with excellent iron loss and manufacturing method thereof technical field The invention relates to a metallurgical steel plate and a manufacturing method thereof, in particular to a non-oriented electrical steel sheet with excellent iron loss and a manufacturing method thereof. Background technique With the continuous improvement of energy saving requirements in countries all over the world, higher requirements are put forward for the efficiency and energy saving of motors and transformers. Non-oriented electrical steel sheets used as iron core materials for motors and transformers also require lower iron loss and lower cost. . In order to solve this problem, the current typical methods are as follows: 1. As a low-iron loss technology for low-cost non-oriented electrical steel sheets with a Si content of 1% or less, Japanese patent documents JP-A-52-2824 and JP-3-215627 disclose the addition of rare earth elements (REM) The purpose of...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C38/06C22C38/14C22C33/04

Inventor 陈凌峰王波刘献东王彦伟

Owner BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com