Opening and cleaning method for axial flow opener for opening picking or blowing carding process and special composite beater device thereof

A technology for blowing, carding, opening and cleaning, applied in the field of composite beater devices, can solve problems such as large fiber damage, and achieve the effects of reasonable opening, high impurity removal efficiency and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

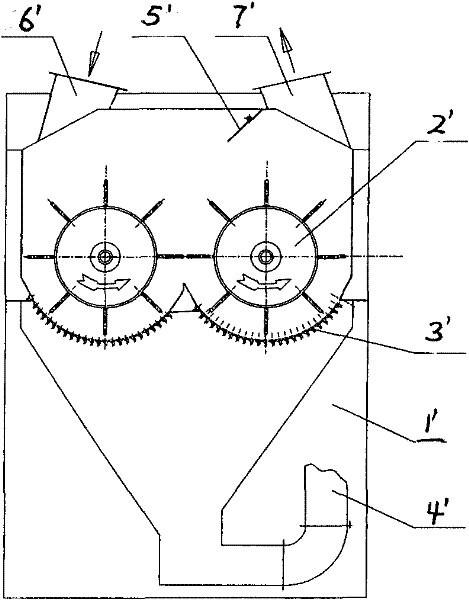

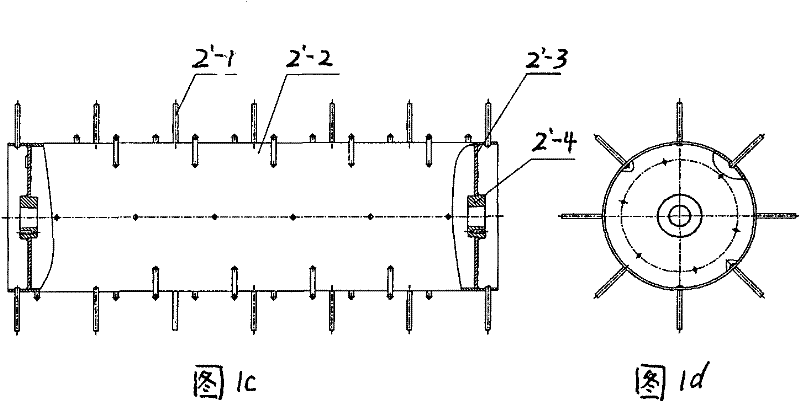

[0066] Such as Figure 4 Shown: the compound beater (1) of the axial flow opener suitable for the open-cleaning or blowing-carding process of the present invention consists of a cylindrical beater barrel (2) and a V-shaped angle nail ( 3), rod-shaped corner nails

[0067] (4), rectangular blade (5) and other components. Rectangular blades, rod-shaped corner nails, and V-shaped corner nails are installed in sequence from the inlet to the outlet, and are distributed on the outer surface of the beater barrel in the form of a spiral. From the inlet to the outlet, the diameter of the beater decreases in turn, that is, ΦD Figure 4a , 4b , 4c).

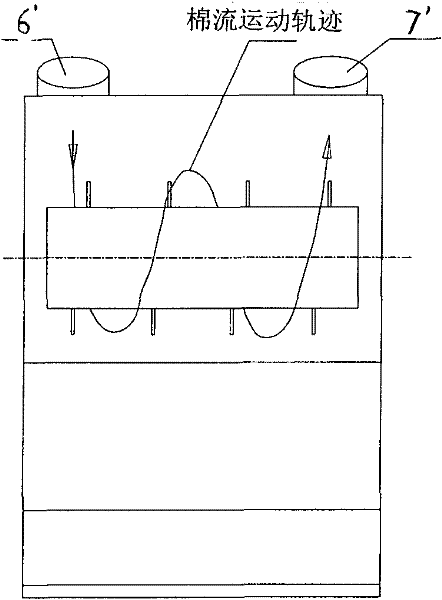

[0068] The opening and impurity removal process is as follows: after the opened cotton block is sent into the beater room, under the combined action of the beater and the air flow, it moves in a spiral line along the beater. The characteristic is that the cotton block moves from the cotton inlet to the cotton outlet. In the spiral movement, the...

Embodiment 2

[0070] Such as Figure 5 Shown: The difference between this embodiment and embodiment 1 is that the beater barrel (2) is in a cone structure, and the rectangular blade (5), rod-shaped corner nails (4), and V-shaped corner nails (3) are imported They are respectively installed in the direction of the outlet, and distributed on the outer surface of the hand barrel (2) in the form of a spiral. From the inlet to the outlet, the diameter of the beater decreases in turn, that is, ΦD Figure 5a , 5b , 5c).

[0071] The working process is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com