Cam control system

A technology of concrete sprayer and cam control, applied in the field of control system, can solve the problems of difficult sealing of oil circuit, unreliable action of oil cylinder, etc., and achieve the effect of precise action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

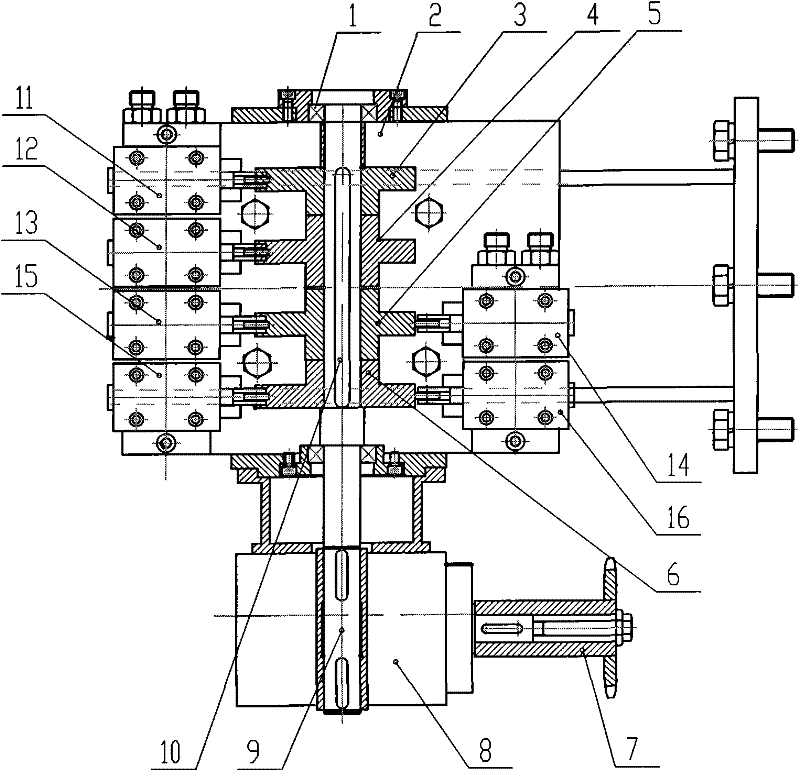

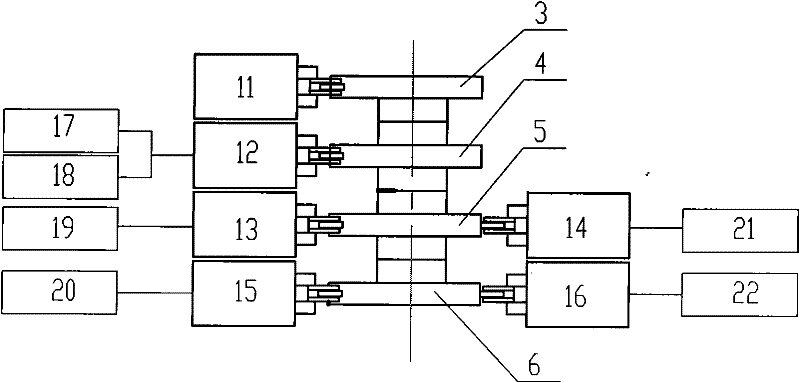

[0011] The present invention will be further described below in conjunction with accompanying drawing:

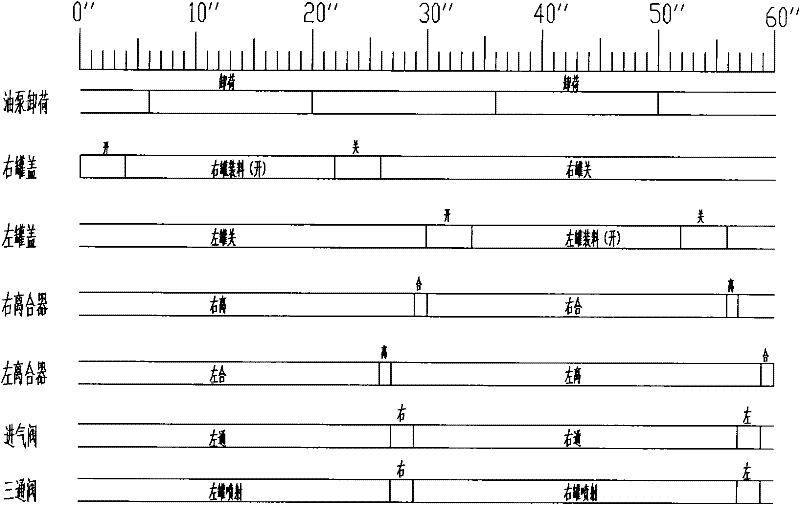

[0012] Depend on figure 1 and figure 2 As shown, a cam control system includes a gearbox 8, a cam seat 2, the input shaft of the gearbox 8 is connected with the sprocket 7, the output shaft is connected with the shaft 9, and the cams (3, 4, 5, 6) are arranged in sequence on the shaft 9 ), the cams (3, 4, 5, 6) are connected with the shaft 9 through the key 10, and each cam is processed with a keyway according to a preset angle, and then installed on the shaft 9. There are several valves on the cam seat 2 corresponding to the cams (3, 4, 5, 6), each valve is connected to a different oil cylinder, and the cams (3, 4, 5, 6) are processed into different shapes according to the pre-calculation , through the different rotation angles to control the switch of each valve, thereby controlling the expansion and contraction of the oil cylinder, and further controlling the various a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com