Temperature-control variable-pressure heat accumulator control system and control method thereof

A control system and heat accumulator technology, applied in heat storage equipment, heat exchanger types, indirect heat exchangers, etc., can solve the problems of unreasonable setting, poor use effect, large flow and pressure fluctuation range, etc. The effect of equipment accident rate, large output and stable steam pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

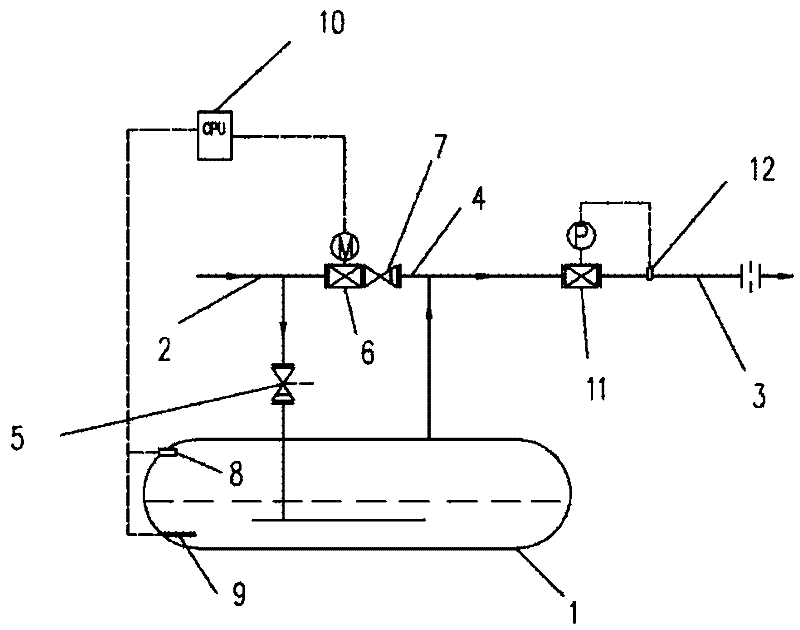

[0015] like figure 1 As shown, the temperature-controlled variable pressure heat accumulator control system described in this embodiment mainly includes a heat accumulator 1, and the heat accumulator 1 is connected with a steam inlet pipeline 2 and a steam outlet pipeline 3 respectively. 2 and the steam outlet pipe 3 are provided with a short-circuit pipe 4 to communicate with each other, and an inlet check valve 5 is provided on the steam inlet pipe 2 between the short-circuit pipe 4 and the heat accumulator 1, and an inlet check valve 5 is provided on the short-circuit pipe 4. There is a temperature control regulating valve 6 and a short-circuit check valve 7. The heat accumulator 1 is also provided with a steam pressure sensor 8 for measuring the saturated steam pressure and a water temperature sensor 9 for measuring the water temperature. The steam pressure sensor 8, water temperature The sensing signal of the sensor 9 is input to the controller 10 , and the output of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com