Preparation method of fluororesin-containing conductive plastic bi-polar plate

A technology of conductive plastics and fluorine-containing resins, applied in battery electrodes, circuits, fuel cells, etc., can solve the problems of unfavorable industrial production and slow desolventization process, and achieve the goals of improving chemical stability, overcoming refractory volatilization, and increasing current density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

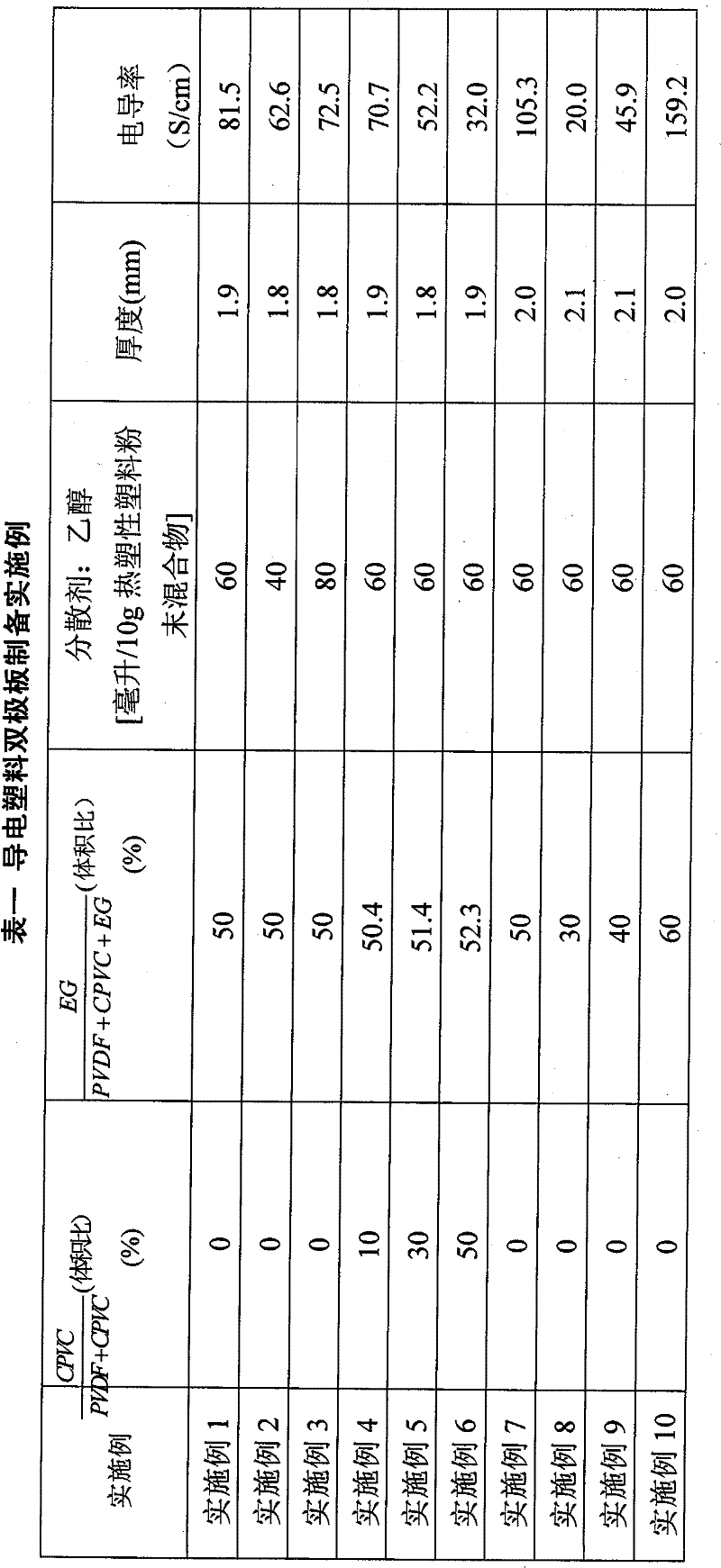

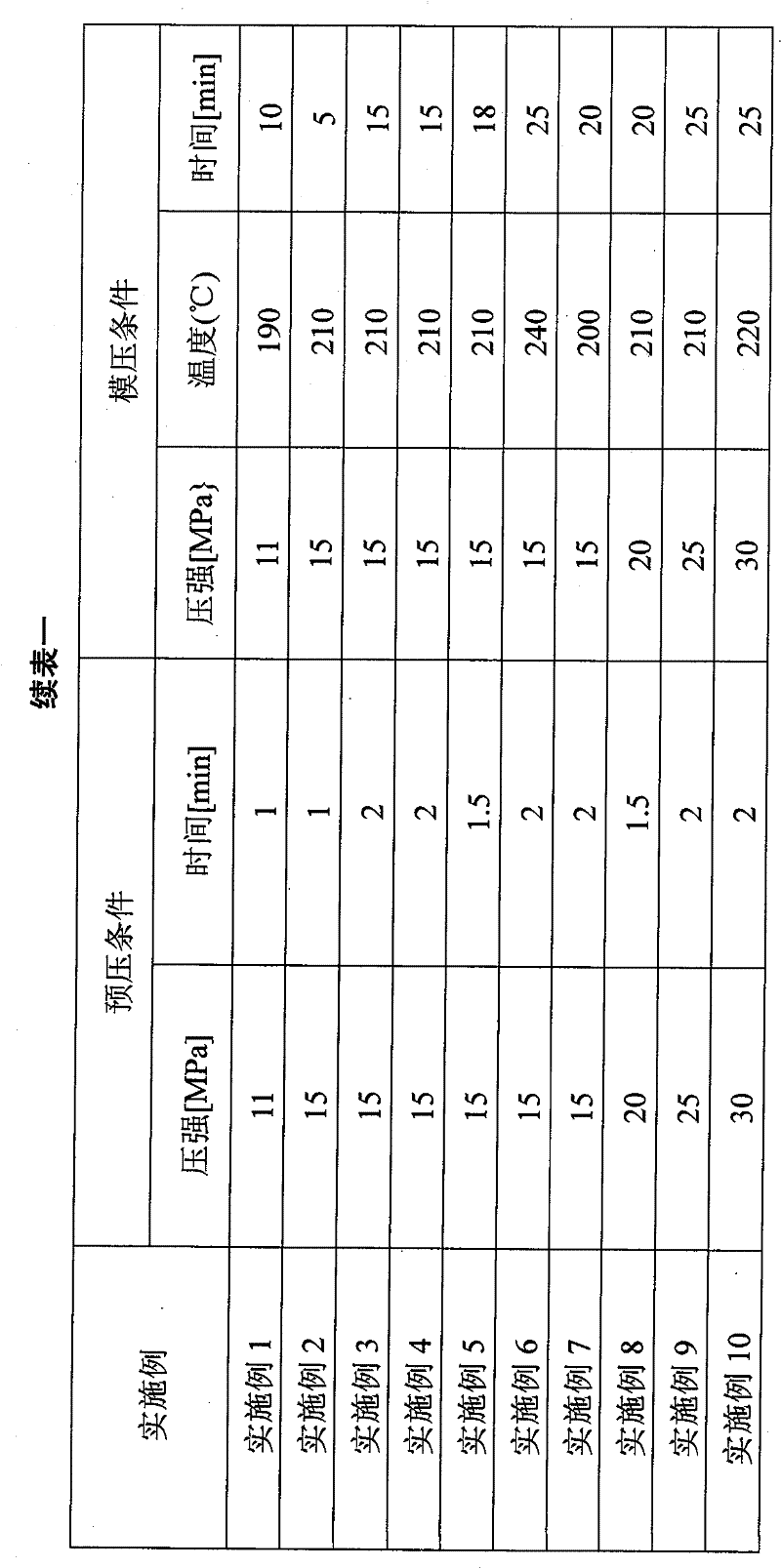

[0019] The present invention carries out according to the following steps successively;

[0020] Step (1): According to adding 40-80 milliliters of ethanol to every 10 grams of powdered thermoplastics, measure, add the measured ethanol to the pre-weighed thermoplastic polyvinylidene fluoride and chlorinated polyvinyl chloride; stir for 2 After ~3 minutes, according to the mass percentage of conductive filler / (conductive filler+thermoplastic) measured between 30% and 60%, add expanded graphite as conductive filler, and fully stir at room temperature to form a slurry.

[0021] Step (2): drying the prepared slurry at 70°C to obtain solid powder;

[0022] Step (3): Put the solid powder in a mold for plastic processing, apply a pressure of 11-30 MPa to pre-press for 1-2 minutes, then gradually raise the temperature to 190°C-240°C for 5-25 minutes, and demould after cooling Become a conductive bipolar plate; its thickness is between 1.9 and 2.0 mm.

[0023] The conductive filler i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com