Oxidization and degradation composite catalyst and use thereof in preparation of spice from carotenoid

A technology of composite catalysts and oxidation catalysts, applied in physical/chemical process catalysts, essential oils/fragrances, chemical instruments and methods, etc., can solve problems such as difficult industrialization, high reaction temperature, and complex oxidation degradation equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Weigh 4.1g β-carotene, 42mg oxidative degradation composite catalyst, where the oxidative degradation composite catalyst is compounded by MgO and kaolin in a ratio of 1:1 by mass, and 43.2g silicone oil, and put them into a 100mL four-necked flask Among them, the silicone oil here can also be replaced by methyl silicone oil, dimethyl silicone oil or phenyl silicone oil, and the effect is the same. The four ports of the reaction bottle are respectively installed with nitrogen inlet pipe, air inlet pipe, thermometer, distillation head, connected to the condenser pipe and tail pipe, and about 30mL of absorption liquid is added to the 100mL round-bottomed flask, connected to the tail pipe and placed in a low-temperature constant temperature reaction bath , connect the outlet of the tailpipe to the buffer bottle, and fill a small amount of silicone oil in the bottle. Turn on the air and nitrogen, respectively check whether the gas path is smooth through the buffer bottle, an...

Embodiment 2、3

[0041] Embodiments 2 and 3 are carried out on the basis of Example 1, after changing the type of the oxidative degradation composite catalyst, the total amount of the oxidative degradation composite catalyst, the ratio between the oxidation catalyst and the degradation catalyst, the specific operation method, etc. 1, the details of the added oxidative degradation composite catalyst and the specific results of the main product mass fraction (%) are compared in Table 2. Wherein the oxidation catalyst is a metal salt oxidation catalyst.

[0042] Catalyst use and result comparison in table 2 embodiment 1~7

[0043]

[0044]

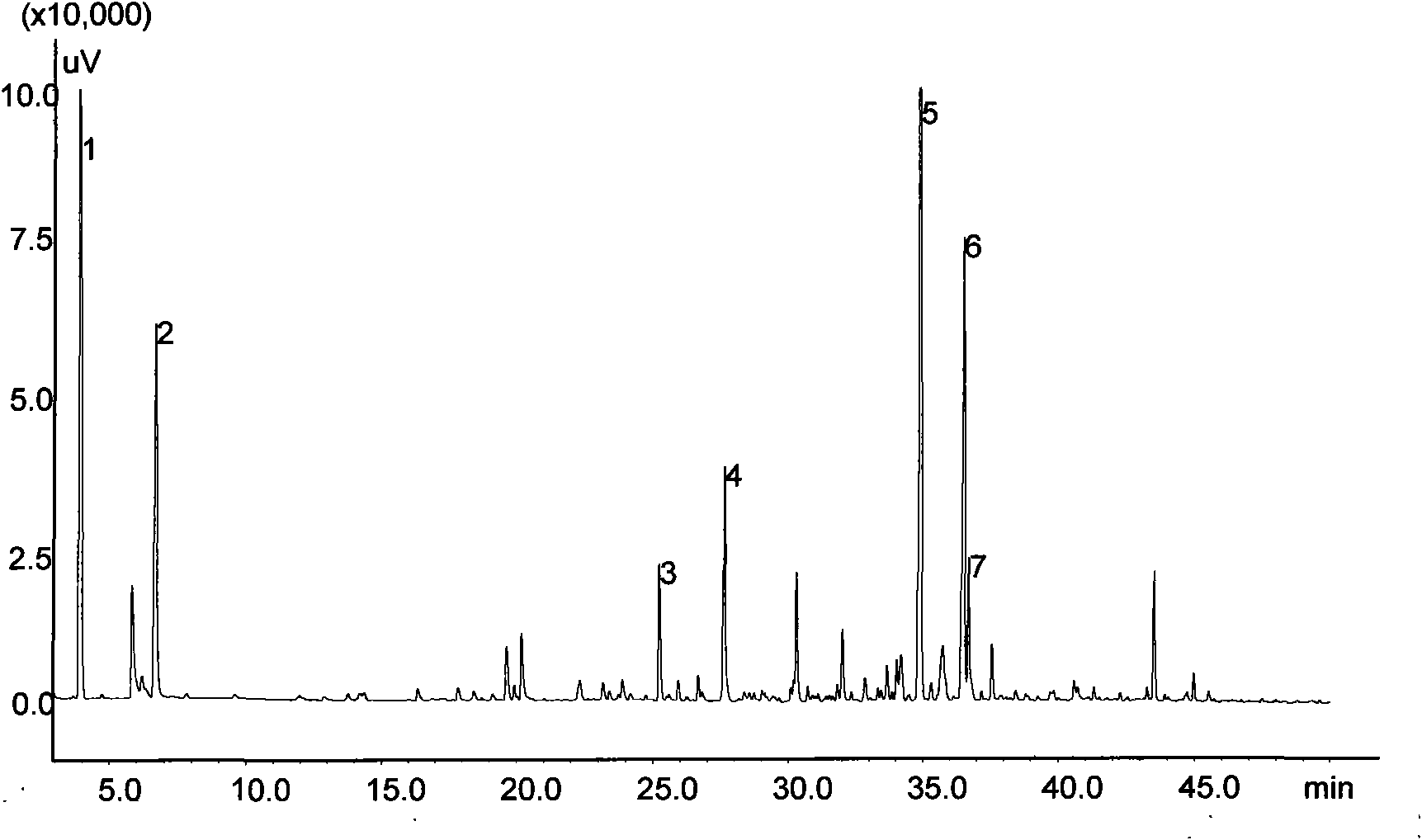

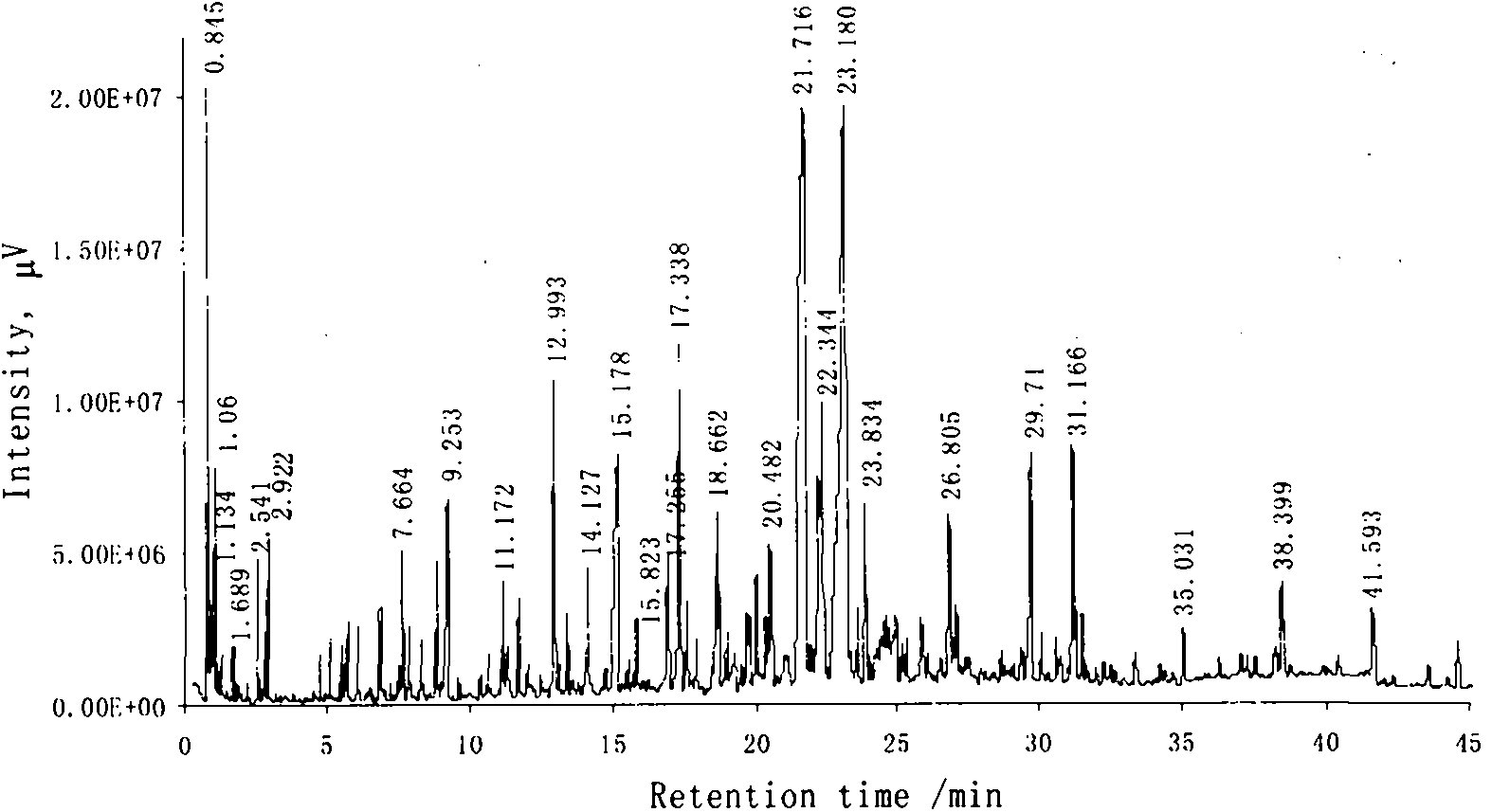

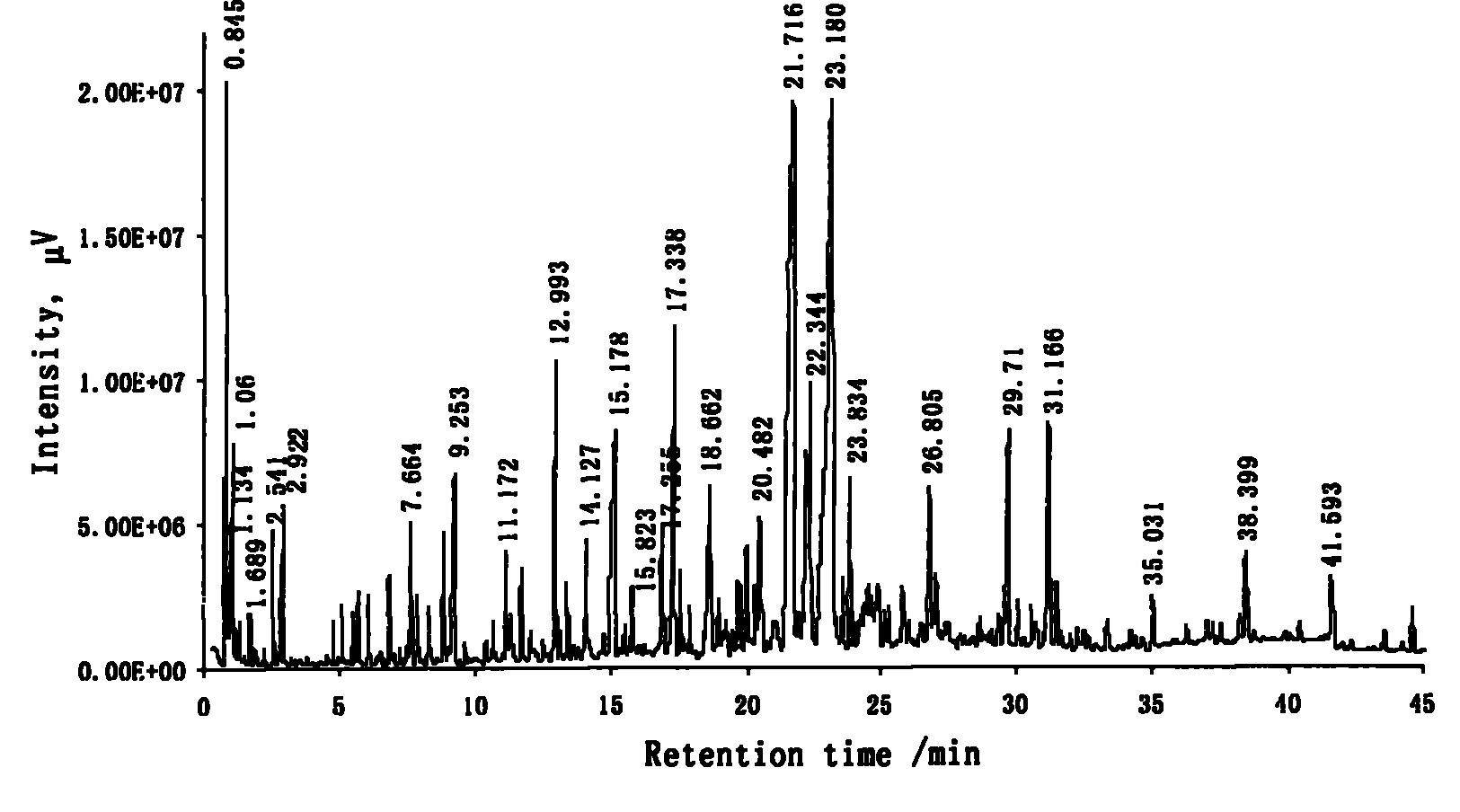

[0045] Note: 1#~7# represent several main components in the product, according to GC retention time (R t ) gradually increasing sequence is: 1#: R t 3.94min, acetol; 2#: R t 6.70min, 2,2-dimethylcyclopentanone; 3#: R t 25.28min, 2,6,6-trimethyl-1-cyclohexene-1-carbaldehyde (β-cyclocitral); 4#: R t 27.64min, 1,4,8-trimethyl-1,7-nonadien-4-ol; 5#...

Embodiment 4~7

[0049] Embodiment 4~7 is on the basis of embodiment 1, the implementation result after changing the mass ratio between oxidation catalyst and degradation catalyst in the oxidative degradation composite catalyst, all the other are the same as embodiment 1, and specific operation method is also the same as embodiment 1, the details of the added catalyst and the specific results of the product are compared in Table 3.

[0050] Catalyst use and result comparison in table 3 embodiment 1, 4~7

[0051]

[0052] Note: 1#~7# represent several main components in the product, and the meanings are the same as those in Table 2.

[0053] As can be seen from the results in Table 3, changing the compounding ratio of the composite catalyst has no effect on the types of main components in the product. Alcohols, ketones, esters, and olefins account for about 60% of the total product mass, but the difference between the components The ratio varies with different catalyst compounding r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com