Cold extrusion mould for double-head pipe joint

A cold extrusion, double-ended tube technology, applied in the direction of metal extrusion dies, etc., can solve the problems of low work efficiency, inability to demold, difficulty in demoulding the lower die sleeve, middle die sleeve and upper die sleeve, etc. Production efficiency, avoid cutting more material, reduce defective rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

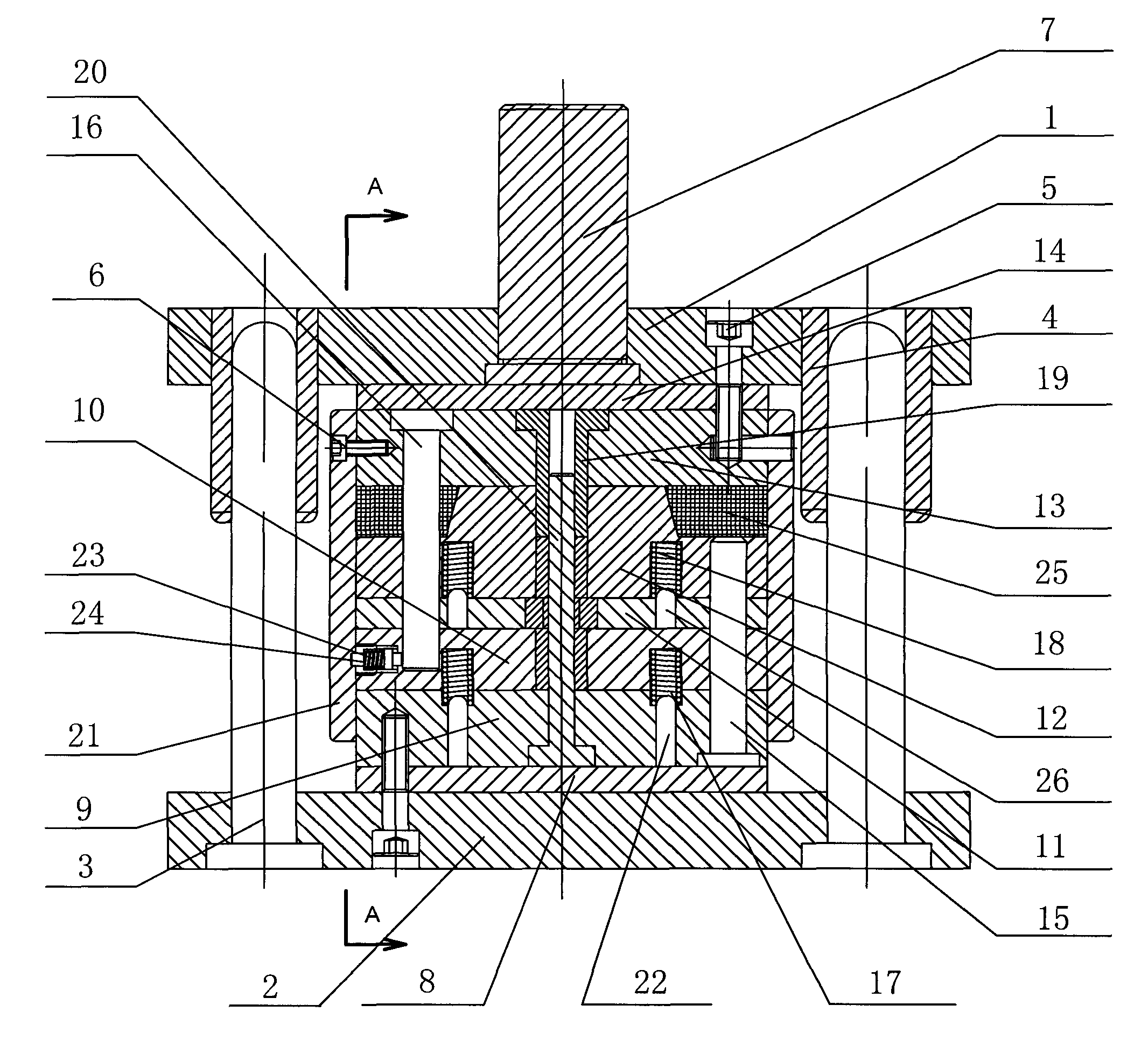

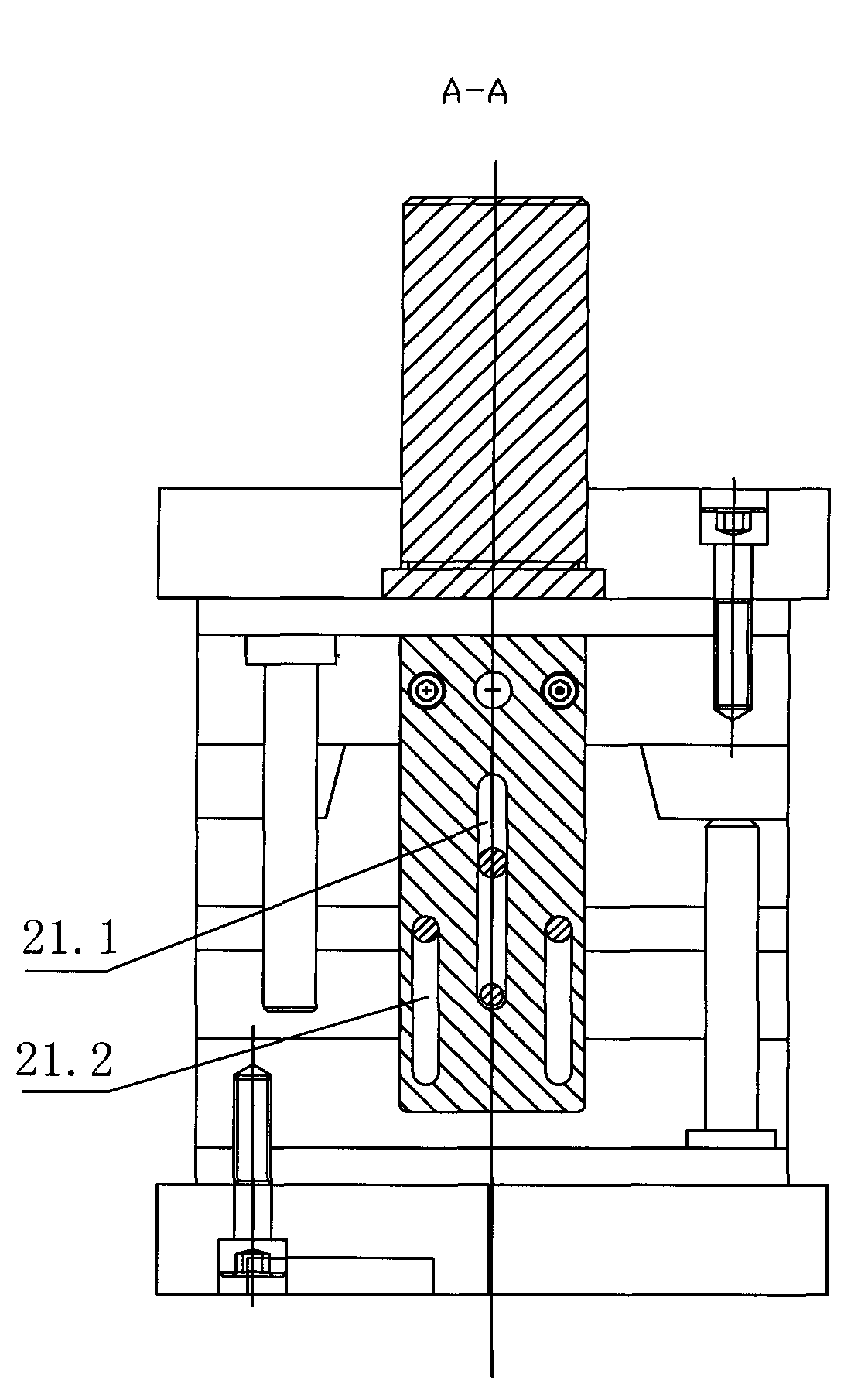

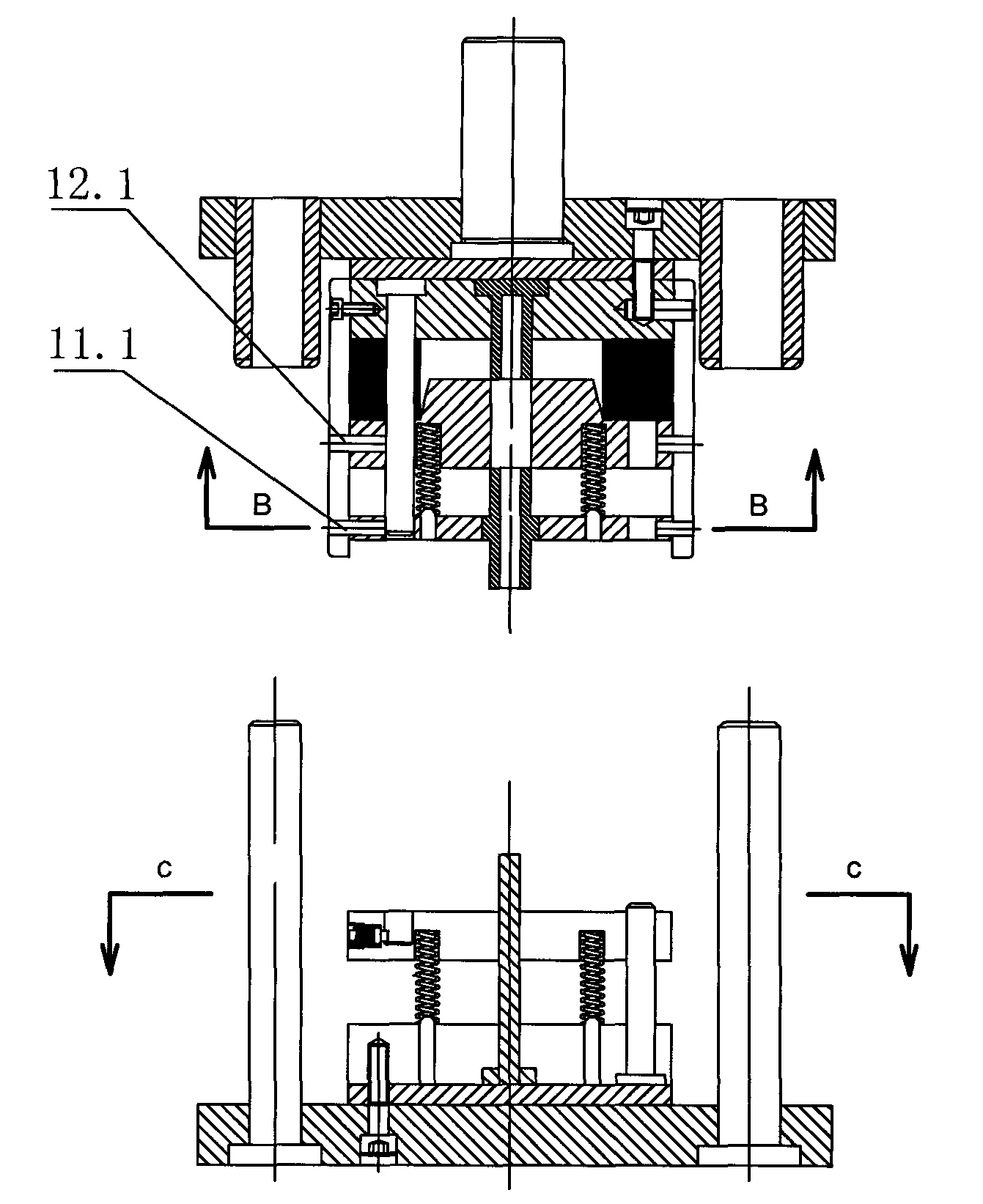

[0022] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0023]The cold extrusion die of the double-ended pipe joint of the present invention comprises an upper template 1, a lower template 2, a guide post 3, a guide sleeve 4, a bolt 5, a screw 6, a mold handle 7, and the upper end surface of the lower template 1 as the base surface from the bottom The lower die backing plate 8, the lower die fixing plate 9, the lower die cover 10, the middle die cover 11, the upper die cover 12, the upper die fixing plate 13, and the upper die backing plate 14 are successively installed on the top, and the middle die cover 11 The cavity cross-section is pentagonal; the ejection device I is provided between the lower die fixing plate 9 and the lower die case 10, and the ejection device is provided between the middle die case 11 and the upper die case 12. II; the left and right sides of the upper mold fixing plate 14 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com