Intelligent air-cooled hydraulic punching and shearing machine

A punching and shearing machine and air-cooling technology, which is applied in the direction of shearing devices, shearing machine equipment, metal processing machinery parts, etc., can solve problems such as the temperature rise of hydraulic oil, achieve the effect of ensuring stable operation and improving cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention. All equivalent technical solutions also belong to the scope of the present invention, and the patent protection scope of the present invention should be limited by the claims.

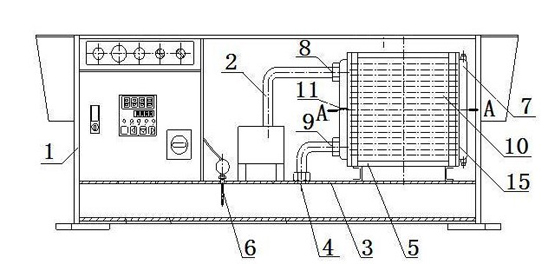

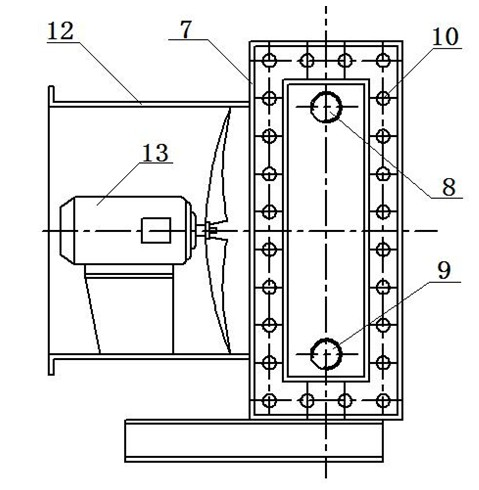

[0019] from figure 1 and figure 2 It can be seen from the above that an intelligent air-cooled hydraulic punching and shearing machine includes a frame 1, an oil return pipe 2 and an oil tank 3, the oil tank 3 is welded on the frame 1, and the oil tank 3 is provided with an oil return The port 4 is characterized in that an air cooling device 5 is arranged between the oil return pipe 2 and the oil return port 4 .

[0020] A temperature controller 6 is provided on the fuel tank 3 , and the temperature controller 6 controls the opening and closing of the air cooling device 5 .

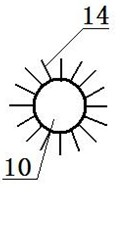

[0021] The air cooling device 5 includes a casing 7, an oil inlet 8 and an oil outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com