Vacuum degassing and automatic boosting continuous ink supply system of large-format printer

A vacuum degassing and printer technology, which is applied in printing and other directions, can solve the problems of printing ink breakage, etc., and achieve the effect of flexible and convenient use, improved continuous stability, and stable and continuous ink supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

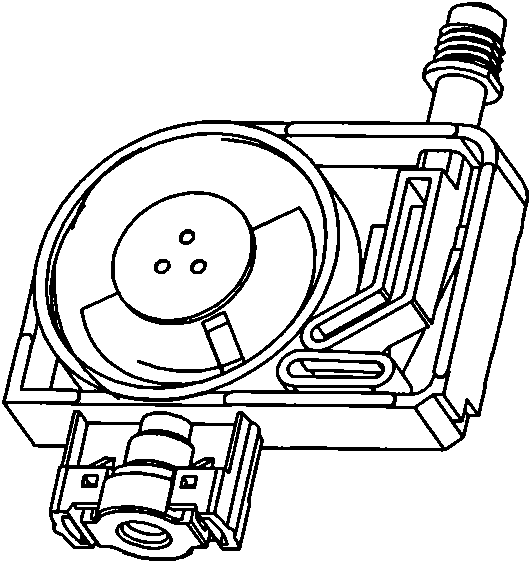

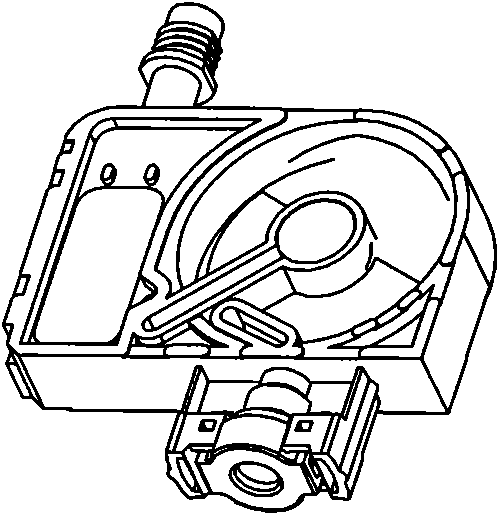

Image

Examples

Embodiment 1

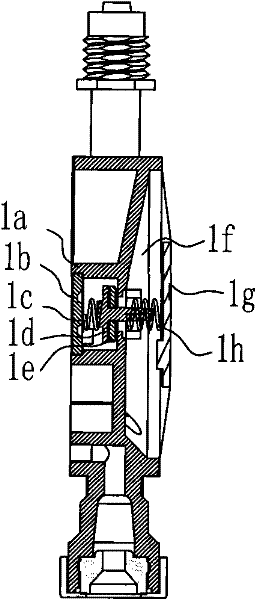

[0074] refer to Figure 6-19 : large-format printer vacuum degassing and automatic pressurization continuous ink supply system, including a large-capacity ink storage bottle 3, the ink storage bottle 3 is provided with a bottle cap 3A that can be opened and filled with ink, for pouring bottled ink . Described ink storage bottle 3 is provided with air outlet 3b, the first ventilation port 3c, the first water outlet 3d, and described air outlet 3b connects the air pump 7 that degasses the ink in ink storage bottle 3, so The ink storage bottle 3 is sealed under the working state of the air pump 7, the first air vent 3c is connected to the first pressure sensor and the intake valve, and the first pressure sensor and the intake valve work together to make the ink storage Maintain a constant vacuum (negative pressure) A in the bottle 3, and the first water outlet 3d is sequentially connected to the ink suction pump 6 and the sealed container 4 through pipelines; the connecting pipe...

Embodiment 2

[0091] refer to Figure 19 The difference between the present embodiment and the first embodiment is that the press device is a mechanical extrusion device, and the mechanical extrusion device includes a baffle plate 4c on one side of the ink bag and a pressure plate 4g on the opposite side, The pressure plate 4g is connected to the horizontal push rod 4k, and the horizontal push rod 4k is penetrated in the fixed plate fixing plate 4h for guiding the horizontal push rod 4k, and the pressure plate 4g and the pressure plate fixing plate 4h are connected with The third spring 4i. Such as Figure 19The magnet 4e that cooperates with the magnet sensor is heat-sealed on the inner surface of the ink bag 4d with a plastic film, and the pressure plate 4g with the third spring 4i is used to press the ink bag 4d on the outer surface of the ink bag 4d, and the pressure plate fixing plate 4h is used In order to ensure that the pressure plate 4g moves horizontally and stably in the H dire...

Embodiment 3

[0093] The difference between this embodiment and the first embodiment is that the sensor is a liquid level sensor, and the other structures and implementation methods of this embodiment are completely the same as those of the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com