Tray revolution lifter

A lift and pallet technology, applied in the field of conveying machinery, can solve the problems of limited conveying goods, unrealizable construction, and low conveying efficiency, and achieve the effects of wide coverage, high operation efficiency and high transmission efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

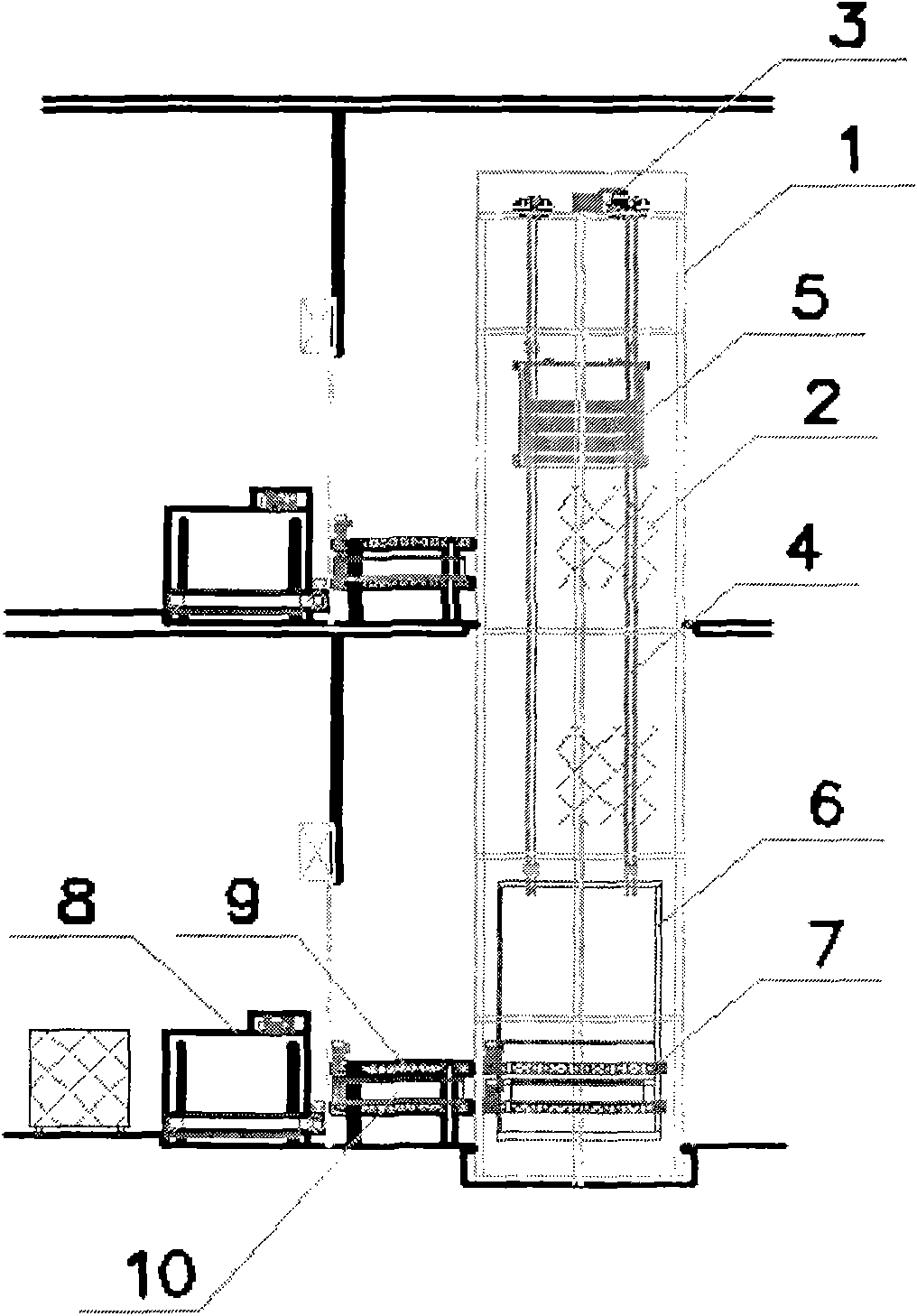

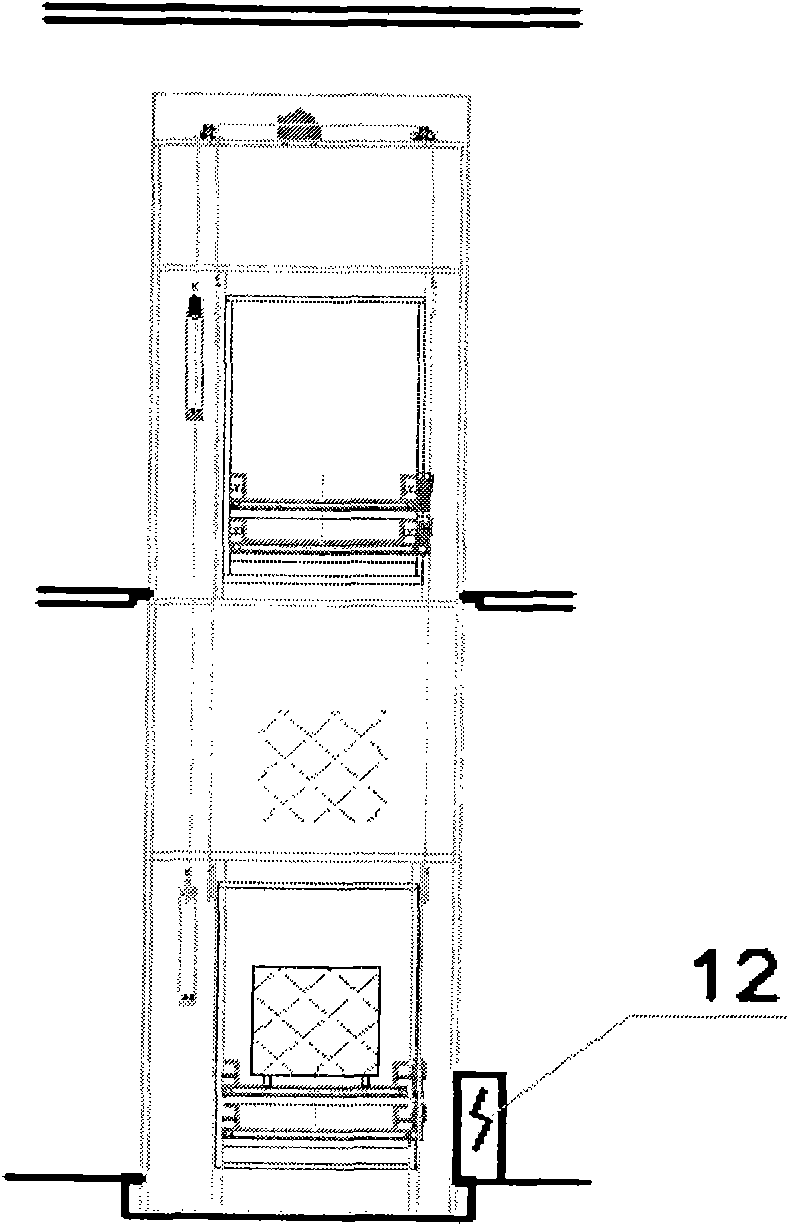

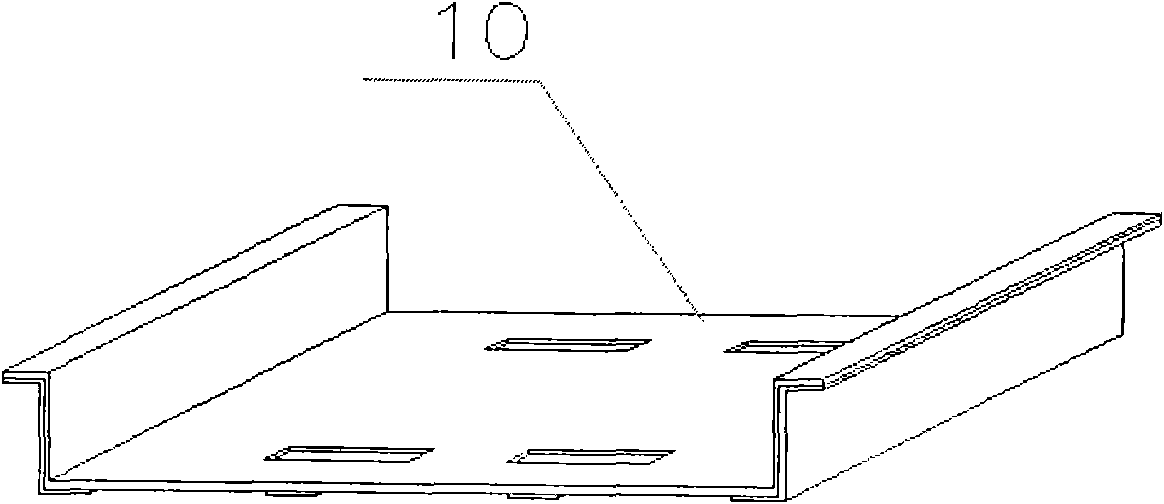

[0018] Such as figure 1 , figure 2 , image 3 As shown, the pallet turnover elevator includes a steel frame 1, a safety shield 2, a motor drive device 3, a chain 4, a counterweight 5, a lifting frame 6, a power roller machine 7, an elevating conveyor 8, a roller conveyor 9, and a pallet 10. Detection element 11, PLC control box 12 and electrical protection element (not shown in the figure), the power roller machine is a double-layer power roller conveyor, the roller conveyor is a double-layer roller conveyor, and the safety shield is Safety shield plate or safety shield net, steel skeleton 1 constitutes the frame, the outside is sealed with safety shield plate or safety shield net 2, motor drive device 3 is installed on the top, four parallel chains 4 are installed on the drive device, and one end of the chain is set A set of counterweights 5 is installed, the other end is equipped with a lifting frame 6, a double-layer power roller machine 7 is installed in the lifting fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com