Device for bending up flexible sheet

A sheet and software technology, applied in the directions of transportation and packaging, separation of objects, and sending of objects, can solve the problems of affecting the quality of printing, labor-intensive, and difficult to eliminate static electricity of sheet materials, and achieve high work efficiency and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

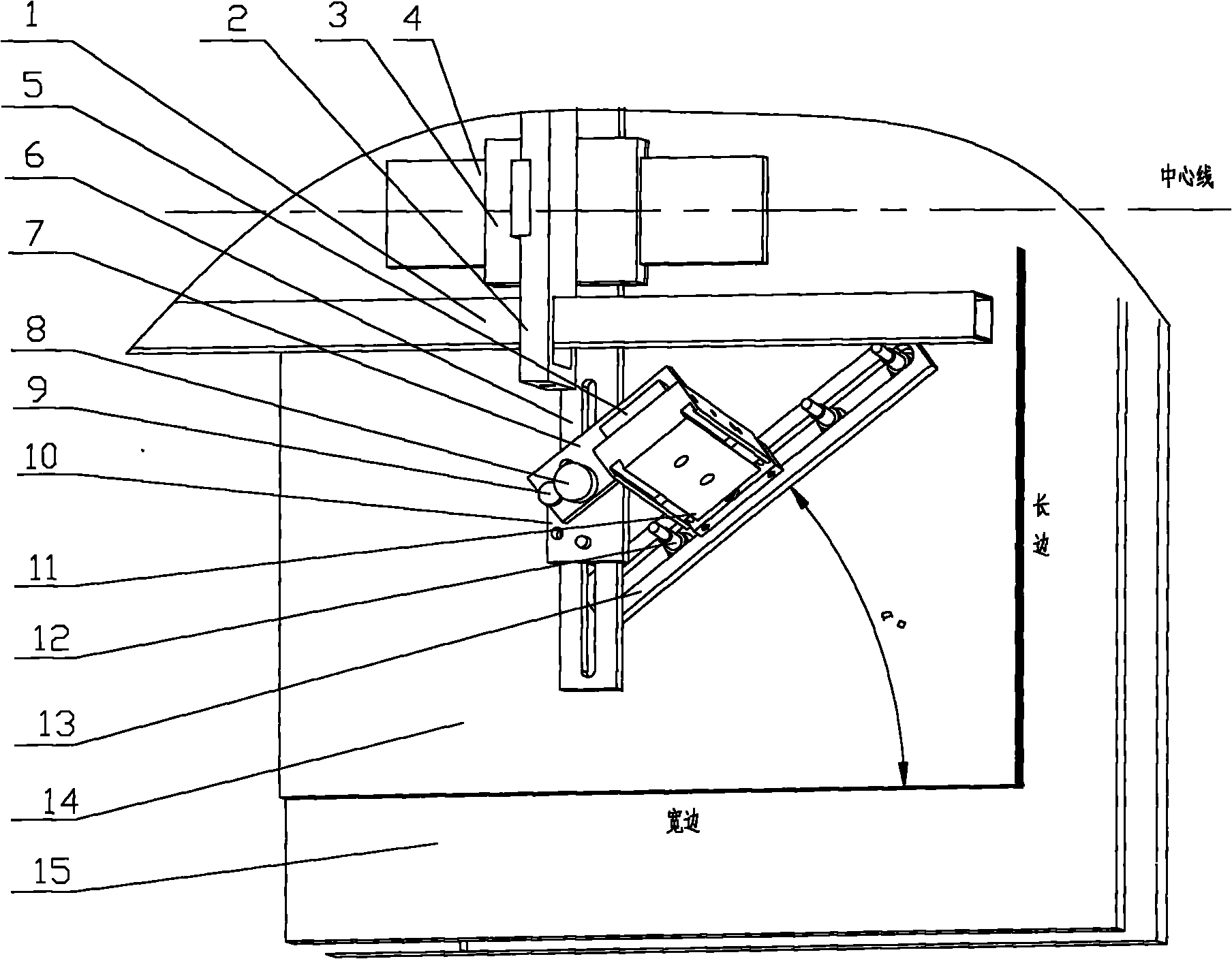

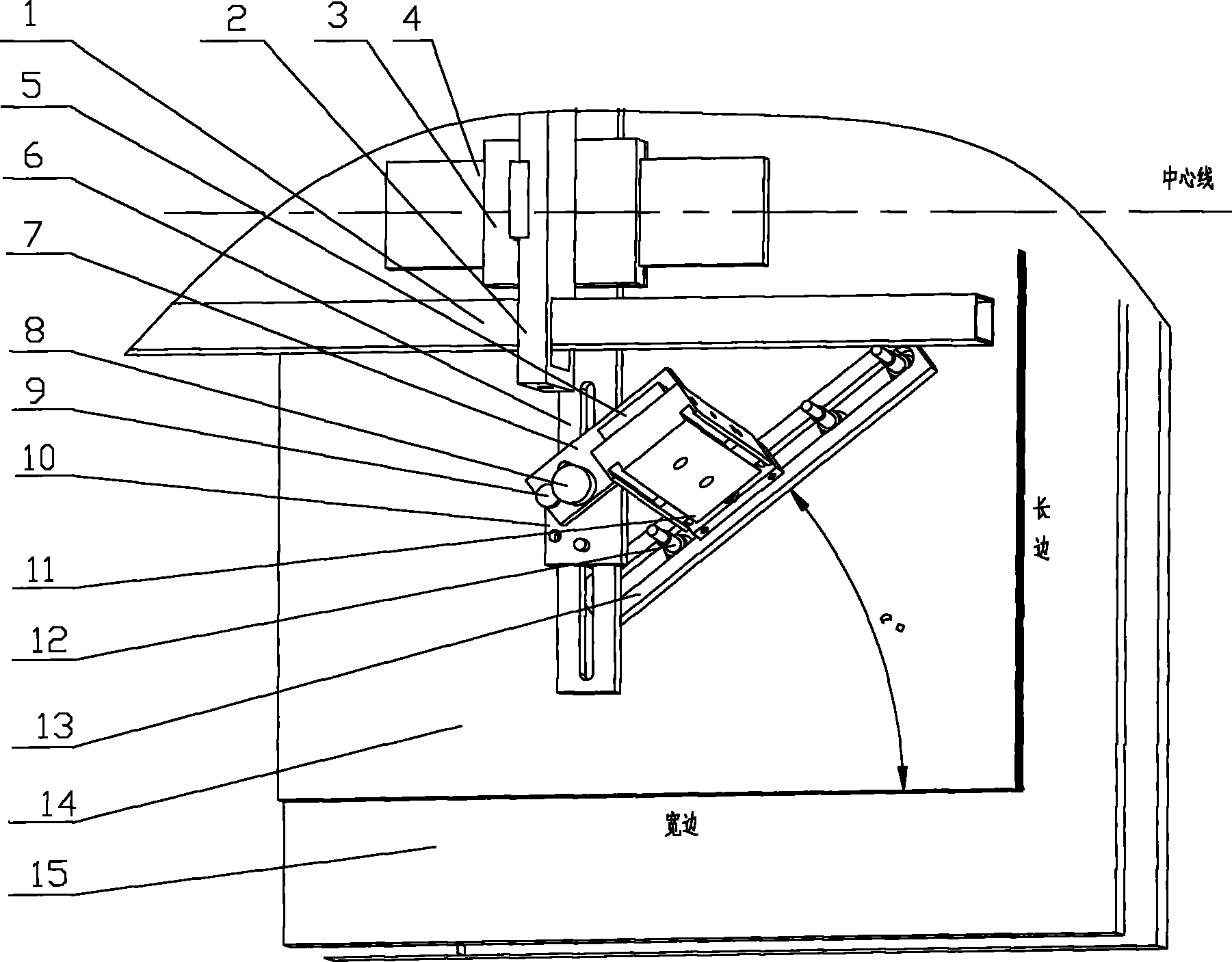

[0011] As shown in the attached figure: a soft sheet bending device, including a beam 1, a main board 2, a guide groove 3, a cross plate 4, a cross bar 6, a fixing groove 10, a rotating shaft 9, a rotating plate 7, and a locking nut 8. Cylinder 11, cylinder mounting plate 5, sucker plate 13 and sucker 12, said beam 1 is equipped with main board 2, main board 2 is provided with guide groove 3, and guide groove 3 is provided with transverse plate 4, transverse plate 4 and The crossbar 6 is connected. When the crossbar 4 is adjusted along the guide groove 3, the crossbar 6 can be driven to move. When adjusting, it can rotate around the rotating shaft 9. The rotating plate 7 is provided with a lock nut 8 for locking the rotating plate 7. The cylinder 11 is connected to the rotating plate 7 through the cylinder mounting plate 5, and the cylinder 11 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com