Friction transmission rotation driving device

A technology of slewing drive and friction transmission, which is applied in the direction of transmission devices, electromechanical devices, electric components, etc., can solve the problems of large load, low precision, and the inability to meet the requirements of high motion stability and high reset accuracy of precision instruments, and achieve stroke The effect of large, high transmission resolution, high motion stability and transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

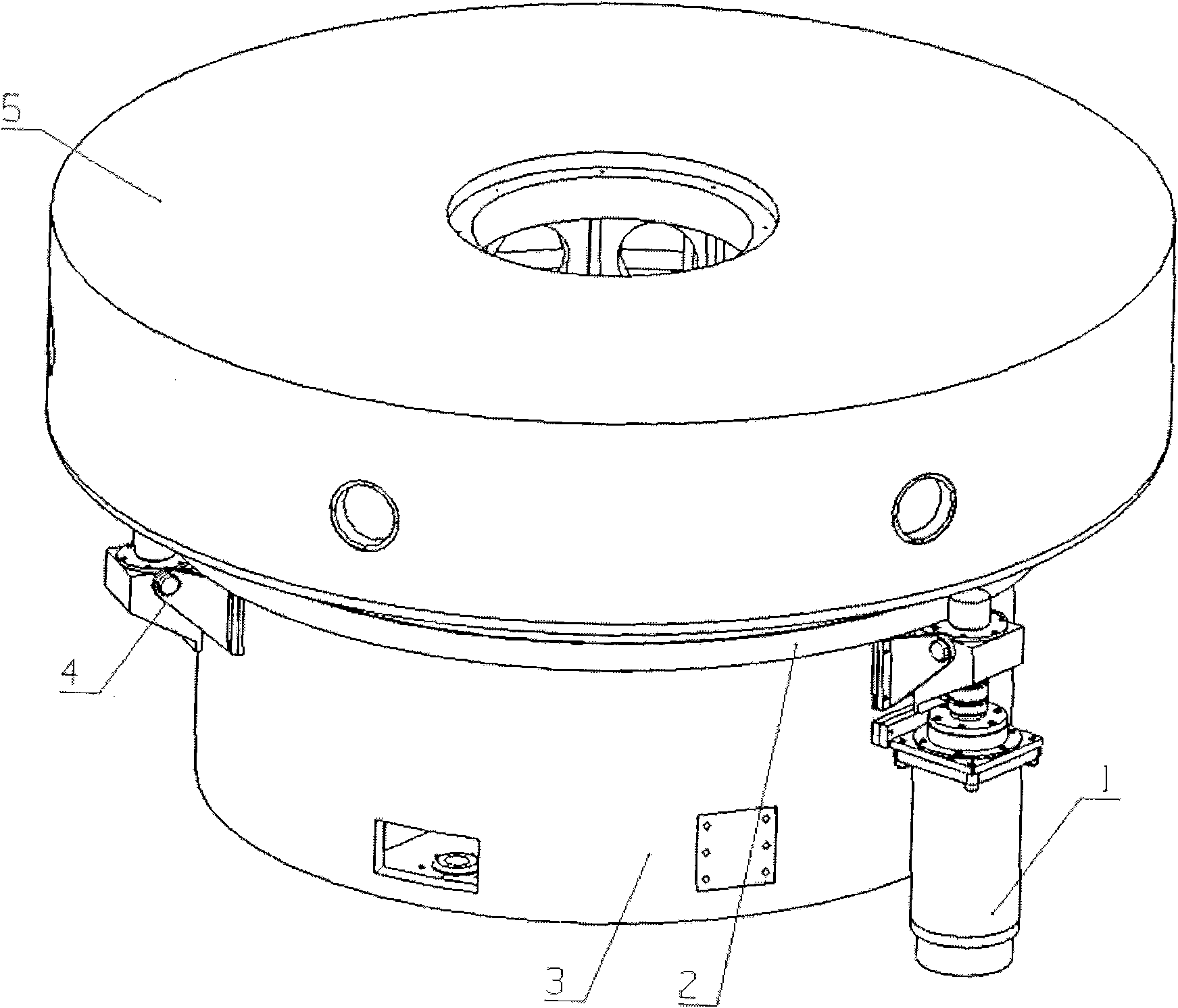

[0018] Such as figure 1 As shown, the friction transmission rotary drive device of the present invention includes a drive wheel assembly 1, two follower wheel assemblies 4, and a friction ring 2. The friction ring 2 is firmly connected to the turntable 5, and the driving wheel assembly 1 and the two follower wheel assemblies 4 are tightly connected to the turntable base 3.

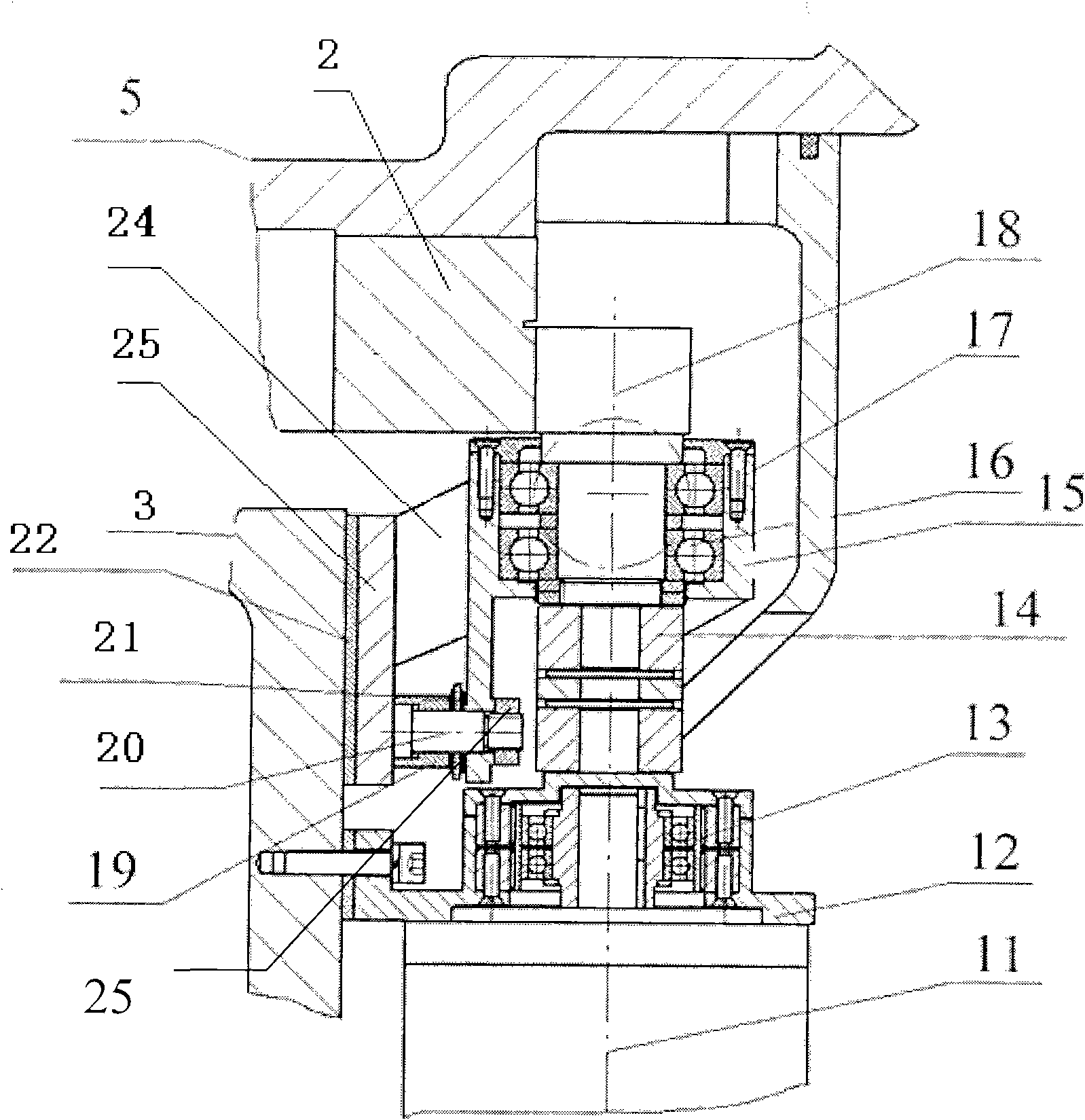

[0019] Such as figure 2 As shown, the drive wheel assembly 1 includes a stepper motor 11, a motor base 12, a harmonic reducer 13, a coupling 14, a drive wheel support frame 15, a drive wheel 18, a first pretension adjusting seat, and a first pretension Force adjustment device; the stepping motor 11 and the harmonic reducer 13 constitute a power unit, which is firmly connected to the turntable base 3 through the motor base 12; the input end of the harmonic reducer 13 and the output shaft of the stepping motor 11 In direct series connection, the output shaft of the harmonic reducer 13 is flexibly connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com