Novel closed-type halogen-tungsten automobile headlamp

A closed-type technology for automotive headlights, which is applied to lighting devices, fixed lighting devices, lighting and heating equipment, etc. , Avoid the effect of dark area and high light utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

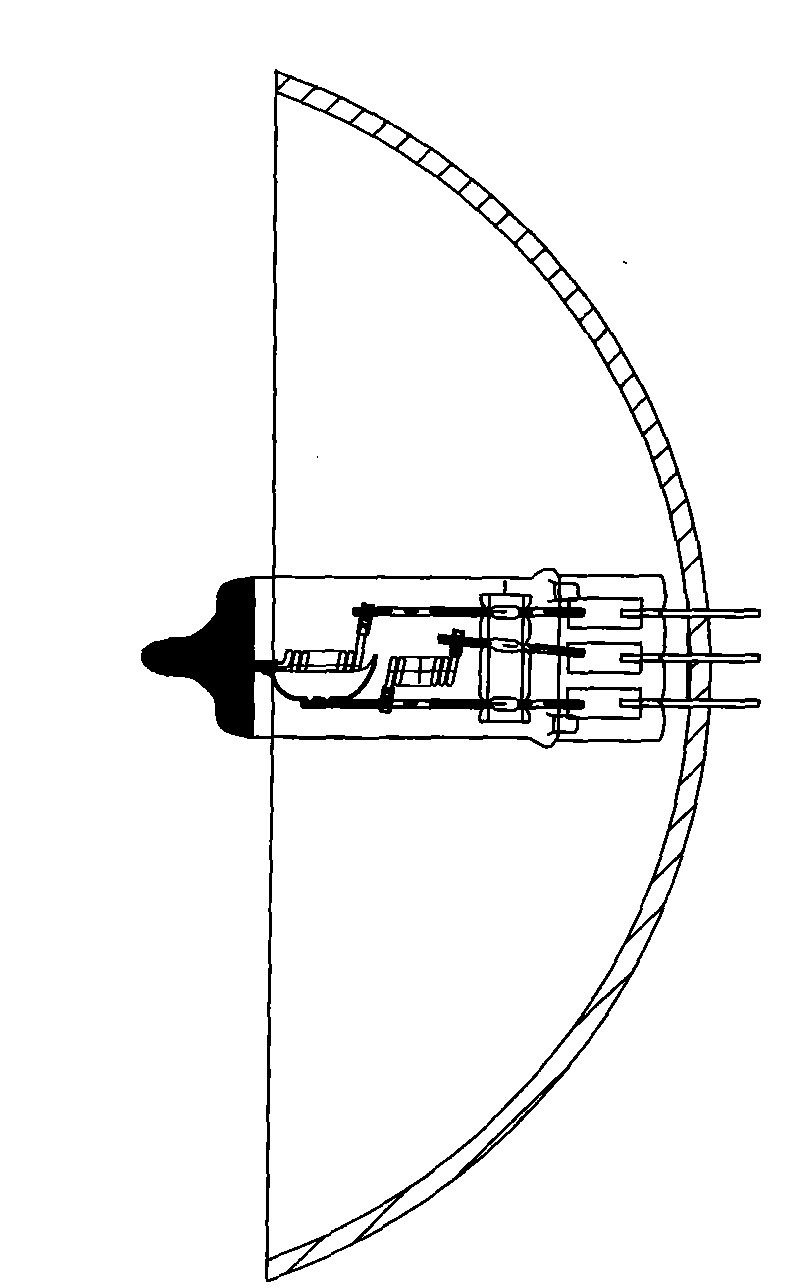

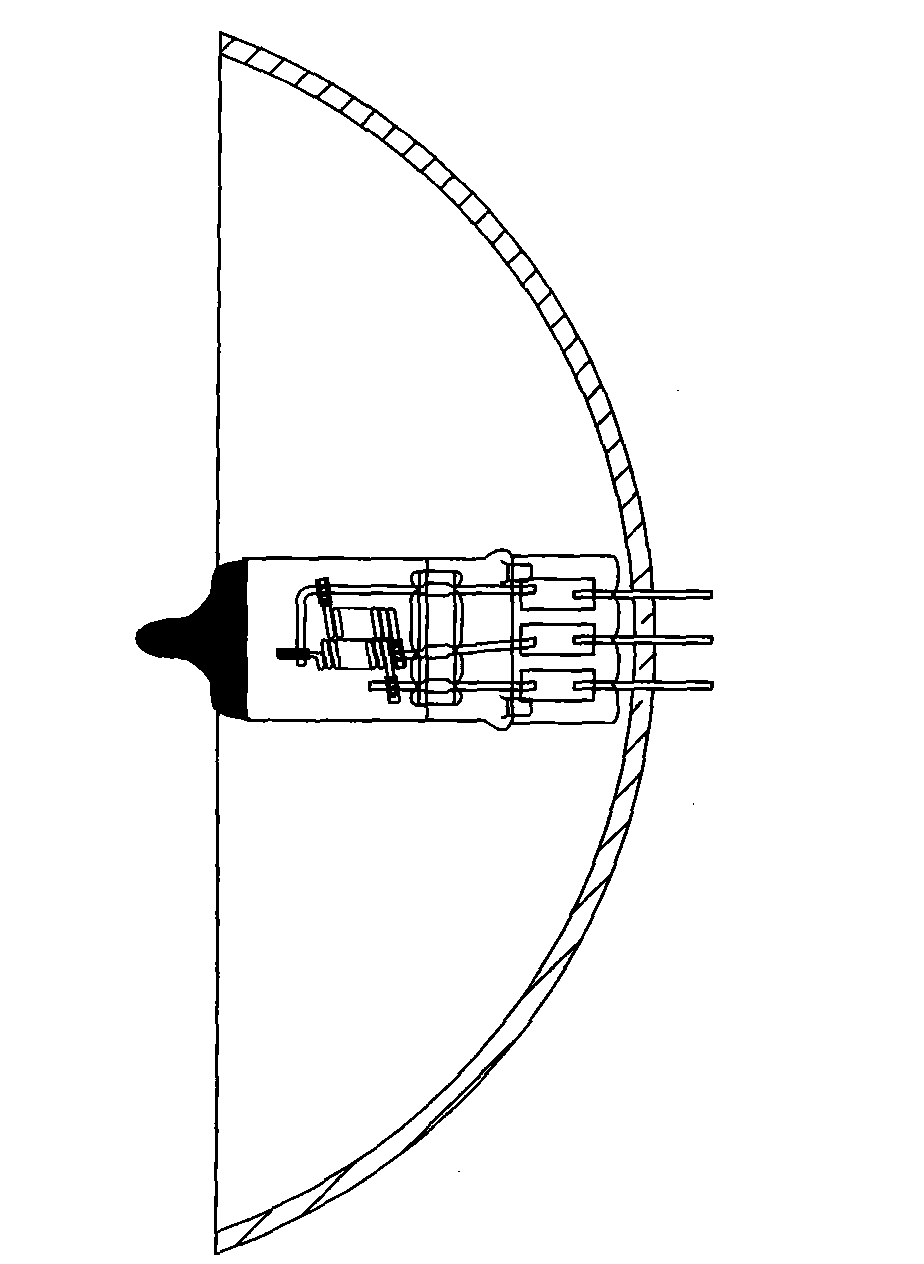

[0025] refer to Figure 4 and Figure 5 , a new type of closed halogen tungsten automotive headlamp, comprising a lampshade 1, a lamp body 2 and a luminous body 3, the inner surface of the lamp body 2 is provided with a reflective curved surface 4, and the luminous body 3 is installed on the lamp body 2 rear end, the front end of the lamp body 2 is connected to the lampshade 1, a groove 5 is provided in the center of the bottom of the reflective curved surface 4, and the tail of the illuminant 3 is located in the groove.

[0026] The illuminant is an H4 type halogen hair-bubble illuminant, and the high-beam filament and the low-beam filament of the illuminant 3 are arranged in front and back. Or: the illuminant is a halogen hair bulb illuminant, and the high-beam filament and the low-beam filament of the illuminant are arranged side by side.

[0027] The depth of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com