Flow transmitter provided with double differential pressure sensors and pressure difference measurement method

A flow transmitter and sensor technology, which is applied in the direction of measuring fluid flow by measuring differential pressure, volume/mass flow generated by mechanical effects, etc., can solve problems such as complexity, high cost, and the inability of low-pressure differential sensors to withstand high pressure differential, and achieve The effect of widening the measurement range and overcoming technical difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

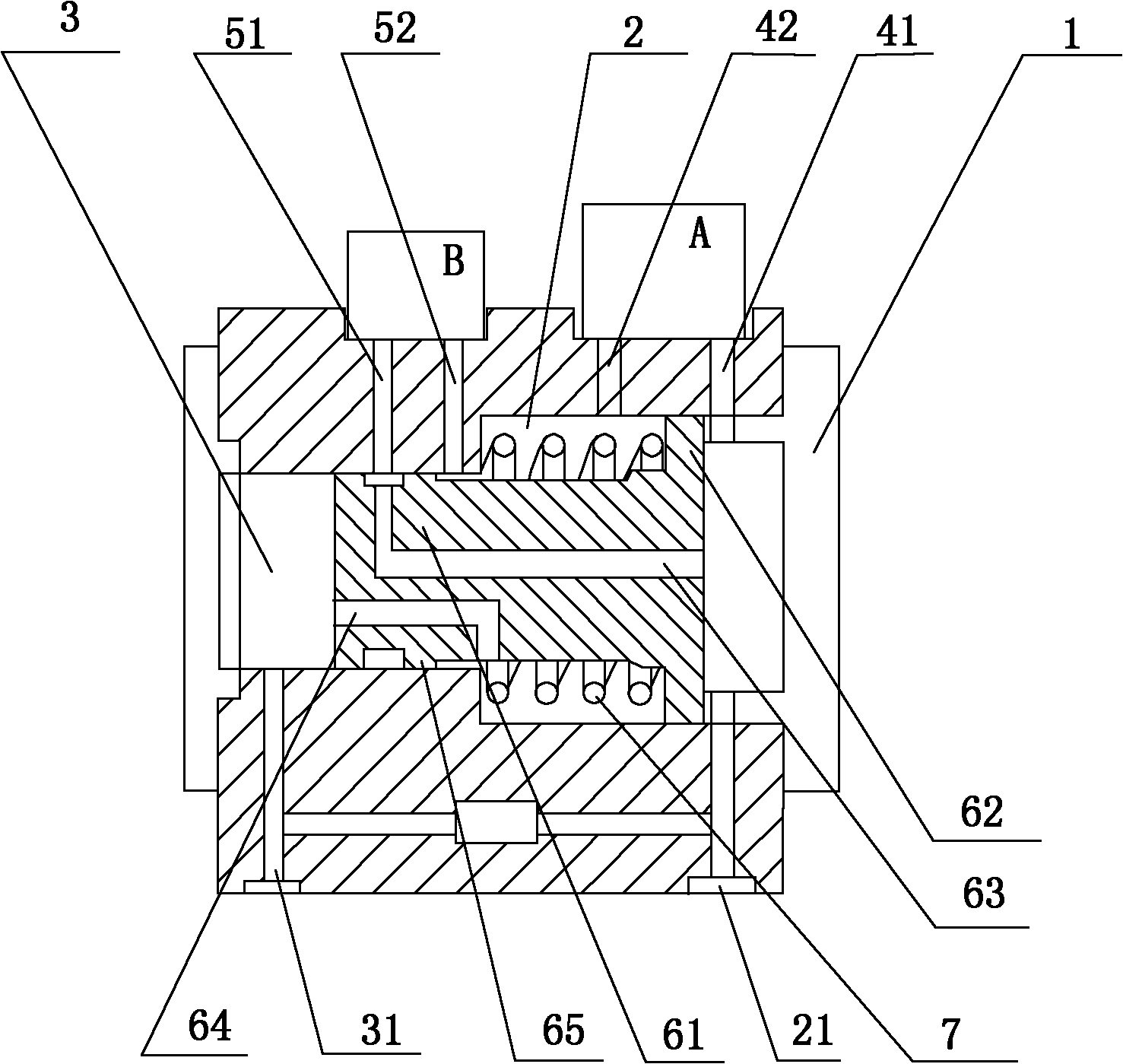

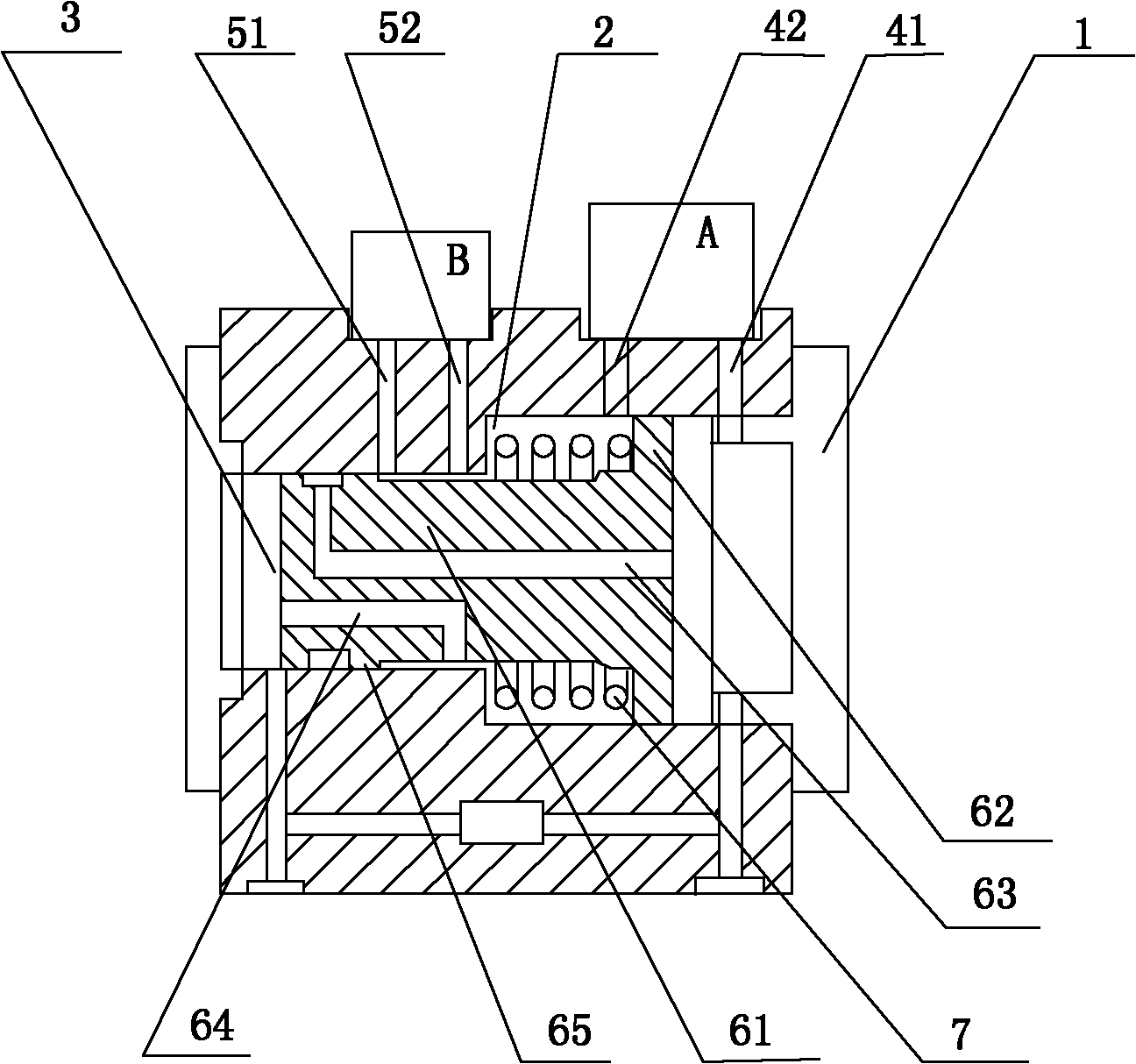

[0025] Embodiment 1: as figure 1 , the end side of the cylinder 61 of the piston 6 is in a sealed state with the inner wall of the small cavity 3, the rest of the cylinder 61 is not sealed, and the elastic component 7 is a spring. When the spring is not compressed, that is, when the piston 6 is not moving, corresponding to the positions of the two low-pressure differential measurement module (B) measuring holes 51 and 52 on the small chamber 3, an annular sealing step 65 is provided on the cylinder 61, and the barrier height Low-pressure measuring holes 51, 52. The piston 6 is provided with a high-pressure communication hole 63 and a low-pressure communication hole 64. The high-pressure communication hole 63 is connected to the high-pressure side of the large chamber 2 and the high-pressure measuring hole 51 of the low-pressure differential measurement module (B); the low-pressure communication hole 64 is connected to the piston rod of the small chamber 3. The outside of the ...

Embodiment 2

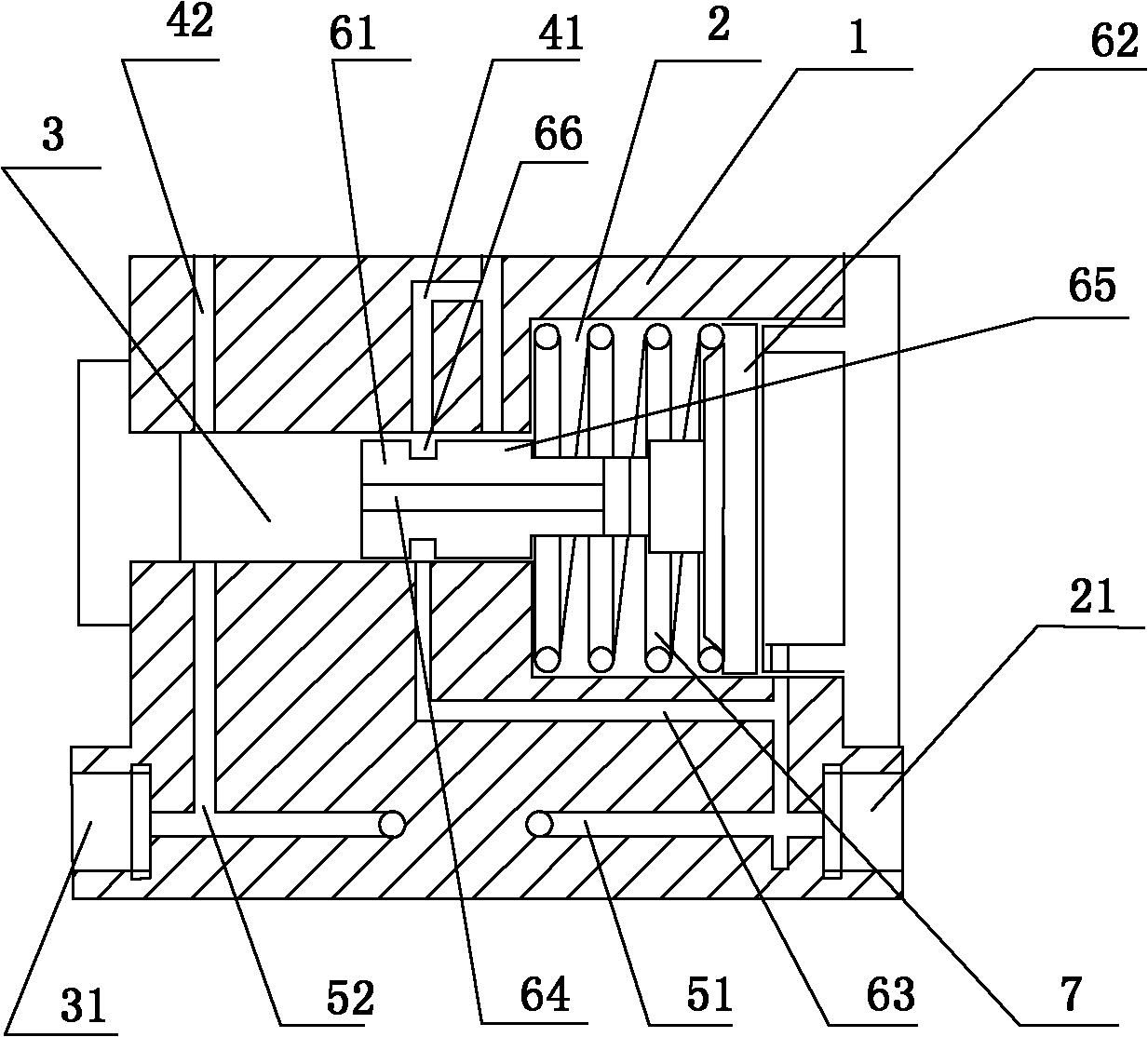

[0029] Example 2: image 3 As shown, the low-pressure measuring hole 42 of the high-pressure differential measurement module (A) is connected to the outside of the cylinder 61 of the small cavity 3; The inner wall is divided into two holes, one is connected to the high pressure measuring hole 41 of the high pressure difference measurement module (A) through the groove 66 on the surface of the cylinder and the high pressure communication hole 63 opened on the shell shell, and the other is blocked by the sealing step 65 . A low-pressure communication hole 64 is opened on the cylinder 61 .

[0030] Figure 4 After the piston 6 moves, the sealing step 65 blocks the passage between the original high-pressure measuring hole 51 and the high-pressure communication hole 6, and opens the connection between the high-pressure measuring hole 51 and the low-pressure side of the large chamber 2. At this time, the low-pressure differential measurement module (B) Both the high and low press...

Embodiment 3

[0031] Example 3: Figure 5, the cylinder 62 is in sealing fit with the inner wall of the small cavity 3, and an annular groove is formed on the cylinder 62, and the high-pressure communication hole 63 is communicated with the high-voltage measuring hole 51 of the low-pressure differential measurement module (B) through the annular groove; the low-pressure communication hole 64 It communicates with the low-pressure measuring hole 42 of the high-pressure differential module (A), and is sealed by the cylinder 62 when the elastic component 7 is not working. At this time, the high-pressure measuring hole 51 of the low-pressure differential measurement module (B) bears the high pressure from the outside of the piston head flange 62 introduced from the high-pressure communication hole 63 and coming through the annular groove.

[0032] Figure 6 , the pressure difference is too large, the elastic component 7 is compressed to the dead point position, and the annular groove connects t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com