Wabbler mechanism of electric seat

A technology of electric seats and electric cylinders, which can be used in chairs, other seating furniture, theaters, auditoriums or similar places, and can solve the problems of large occupied area, non-environmental protection, and pollution of dynamic seats.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

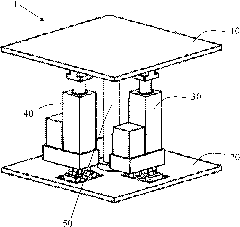

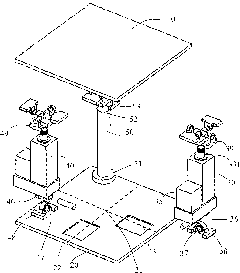

[0024] refer to figure 1 , 2 As shown, the electric seat rocking mechanism 1 of the present invention mainly includes an upper base 10, a lower base 20, a first electric cylinder 30, a second electric cylinder 40 and a support mechanism 50, wherein:

[0025] The bottom end 51 of the support mechanism 50 is affixed to the upper surface center 21 of the lower base 20, and the top end 52 of the support mechanism 50 is connected with the lower surface center of the upper base 10 through a cross universal joint 53. The support mechanism 50 can be adopted as figure 1 fixed-height support columns as shown, alternatively such as Figure 12 electric cylinder shown;

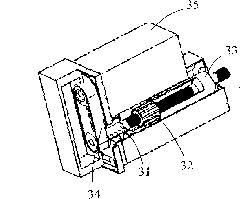

[0026] refer to image 3 , 4 As shown, the first electric cylinder 30 is mainly composed of a ball screw 31, a screw nut 32 and a lifting sleeve 33, wherein the ball screw 31 is in transmission conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com