Full-automatic spin lock for container

A fully automatic, container technology, applied in the field of mechanical design and manufacturing, container transportation equipment, can solve the problem that the container cannot be effectively fixed, and achieve the effect of improving loading and unloading efficiency, transportation safety, convenient operation, and avoiding corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

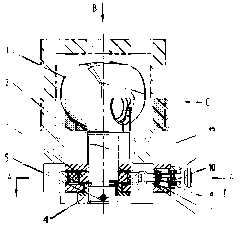

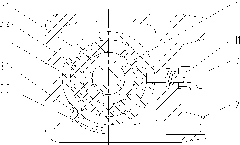

[0025] combine Figure 1 to Figure 7 , figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 A-A direction view, image 3 for figure 1 B direction view, Figure 4 for figure 1 C direction view, Figure 5 It is a structural schematic diagram of the lock shaft of the present invention, Figure 6 It is a schematic structural view of the end cap of the present invention, Figure 7 It is a structural schematic diagram of the lock seat of the present invention. Including lock shaft 1, lock seat 2, torsion spring 3, lock nut 4, connecting pin 5, limit pin 6, emergency release pin 7, round pin 8, washer 9, spring 10 and end cover 11; the lock shaft 1 The lock head 1.1 is an inclined hyperboloid structure, the bottom of the lock head 1.1 is provided with a limit pin 6, the lock rod 1.2 of the lock shaft 1 passes through the lock seat 2, the torsion spring 3, and the lower end is connected with a lock nut 4; using a connecting pin 5 Pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com